Problem:

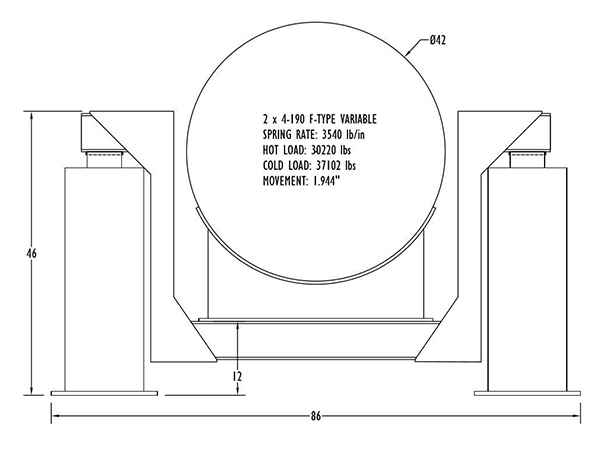

PT&P received an RFI on supporting a Coker duct with a base type spring support, which has been supported by a shoe and a short concrete beam, resting on a long concrete beam that is part of the plant structure.

Customer finding:

The duct needs to move upward for proper running operation and to relieve stress buildup. This can only be done by using a spring support. The short concrete beam below the shoe is only 12” high. Supports found in the market can not fit in a 12” space for the load being applied by the duct. Adding extra structure around and above the duct, for a hanger spring support, is costly.

Data received:

Duct diameter: 42”

Cold load: 36294 lbs

Hot load: 30220 lbs

Movement: 1.94” upward

Spring rate desired: 3125 lb/in

Support Type: Base type

Space available between the bottom of the shoe and main supporting concrete beam: 12”

Solution devised by PT&P:

Since a single support cannot fit underneath the shoe, PT&P explored the possibility of fitting variable supports around the duct, on the supporting beam. When the customer relayed the surrounding dimensions to PT&P, it was decided to use two standard PT&P variable supports and bridge them by using a specially designed bridging assembly.

Keeping in mind that the hot load and movement is what is important to consider for the support assembly, the load and spring rate was split into two to find an appropriate variable spring support set. To keep the assembly as short as possible, a slighter stronger spring rate variable supports were selected that are still within the specs. We could still go to a lighter spring rate variable support. The side effect would be longer variable supports.