Problem:

PT&P received an RFI from a refinery experiencing excessive vibration in the 16” heater outlet pipe. The outlet pipe from the heater was supported by 2 struts (size B), one of which broke due to the vibration. The struts were welded to the heater shell to support the 16” outlet pipe.

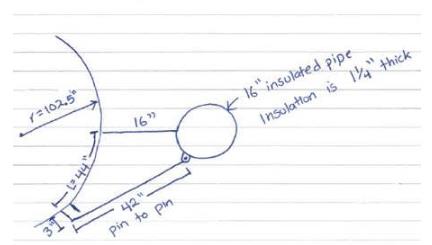

The client provided PT&P a sketch showing approximate dimensions and a couple of pictures.

They wanted PT&P’s expertise in designing more sturdy support that would withstand the vibrations in the outlet pipe.

The engineer at the plant was not sure how to connect the supports to the outlet pipe since the existing struts are connected to the pipe by lug welded to the pipe. They wanted to use the same structure on the heater shell to attach the new supports.

The existing supports were installed prior to 1999.

Picture: Existing struts connecting the 16” heater outlet pipe to the heater shell

Data received:

Load – Size B Struts – 1500 Lbs

Temperature – 600oF

Solution:

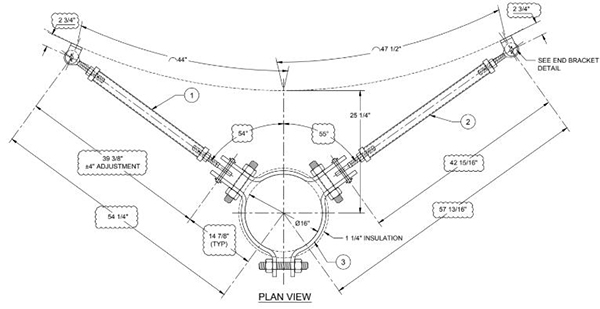

PT&P recommended replacing both the existing struts by one size bigger sway strut with allowable load-carrying capacity of 4500 Lbs. Also, PT&P designed a special Bi-way (three pieces) clamp that can be connected to the two struts and be clamped to the outlet pipe. There is no necessity of welding to the pipe or separate clamps for the two strut assemblies. The strut end brackets will be welded to the same structure on the heater shell that had the existing struts.

PT&P worked with the refinery engineers on gathering the distances of the heater shell structure from the outlet pipe and the outlet pipe centerline from the heater shell.

After several drawing iterations, PT&P submitted the support drawing for the modified design to the refinery engineer.

Summary:

PT&P has the expertise and in-depth knowledge of pipe supports and special designs to provide solutions for every unique scenario.

With minimum information, PT&P can work with the plant engineers directly and recommend solutions for piping problems and pipe support solutions.