Pipe Support and Expansion Joint Manufacturing

One of the major challenges faced by many Pipe Support and Expansion Joint manufacturers is trying to serve Major EPCs, Operating Plants, and Mechanical Contractors. The following is a summary of the needs of these different customer groups:

Figure 1 – Customer Requirements for Different Segments of Customers

| Major EPC | Mechanical Contractor | Operating Plan | |

| Typical Project | New Plant Build | Small Plant Modification | Maintenance in Turnaround |

| Volume Requirements | Large | Small/Medium | Small |

| Lead Time for Products | Long | Short/Medium | Short/Medium |

| Engineering Support from Vendor | Low | Medium | Medium/High |

| Customization Requirements | Low | Medium | Medium |

| Customer Operating Time Horizon | Turnover of Plant in 1 yr. | Varies | 10+ Years |

The challenge for this mix of customers is that the differences in customer needs’ leads to a fundamental set of choices in terms of manufacturing configuration. Figure 1 shows the choices we see in the marketplace. As can be seen from the table, the big difference is in the target customer for which the operation was designed. The following is a summary of Manufacturing Strategies we have seen:

- Steel Fabricator – this type of company is typically founded by someone who is skilled at steel fabrication and is a smaller operation with a group of reasonably skilled fabricators. This type of firm tends to be good at customization but struggles at scale. It is also typically pushing for any work it can get with the goal of ultimately attaining scale.

- Mass Production – almost all of the larger-scale firms in the industry fall into this category. For a steel fabricator, a transformation into mass production is a natural outcome of serving the Major EPCs. The volumes seen from major EPCs can dwarf other segments. In addition, major EPCs tend to allocate far more resources to purchasing and vendor management than other customers (Purchasing is actually the middle man). As a result, we have seen most major players migrate aggressively to this setup.

- PT&P Mass Customization – PT&P’s approach is unique in the Pipe Support and Expansion Joint market. The fundamental reason for this is that our DNA is not Steel Fabrication. PT&P was founded as a Pipe Stress Engineering company and migrated into manufacturing over time from the encouragement of our customers. We grew the business from serving operating plants to partnering with Major EPCs but never left our origins of serving operating plants. Fundamentally, serving the tremendously varying needs of different customers has become an engineering problem to be solved for PT&P.

Figure 2 – Manufacturing Approach for Pipe Support / Expansion Joint Manufacturers

| Steel Fabricator (Owner/Operator) | Mass Production | PT&P Mass Customization | |

| Machinery | Simple | Scale | Scale and Artisan |

| Advanced Skills (e.g. TIG welding Inconel) | Varies | Limited | Yes |

| Systems | Limited | For Mass Production | Advanced Systems allow Management of Complexity |

| Customization/Flexibility | High | Low | High |

| Short Turnaround | Yes | No | Yes |

| Scale | Low | High | High |

| Outsourced Offshore | No | Yes | No |

| Engineering Knowledge | Low | Medium | High |

| Ability to Manage Contamination Across Materials | ? | No | Yes |

| Breadth of Product Line | Medium | Low/Medium | Large |

| Target Customer | ? | Major EPCs | All |

How Does PT&P Manage Mass Customization?

Most companies do not do mass customization because it is very, very difficult and really takes an engineering, not steel fabrication mindset. The following are some of the key elements that allow PT&P to offer Mass Customization:

- Scale – PT&P has over 500 production employees and 70 Design Engineers at our Houston Headquarters location. With 40+ years in business, we have developed the reputation required to be a scale operator in terms of the quality of our products and reputation within every customer segment.

- Industrial Engineering – PT&P has 10 Industrial Engineers in our manufacturing operation with most having a Master Degree. This provides both the intelligence to manage a high degree of complexity as well as a mindset of making continual process improvements.

-

-

- Centralized Scheduling for 50+ Operations – The key to the operation is the ability to schedule down to the part level in over 50 individual operations. Jobs, Items, and Parts are analyzed on a variety of factors including lead time, natural “clubbing” between different jobs, material, complexity, run time, the status of other parts in the job or item, etc. This leads to a daily schedule for every operation that communicated to every lead and operator.

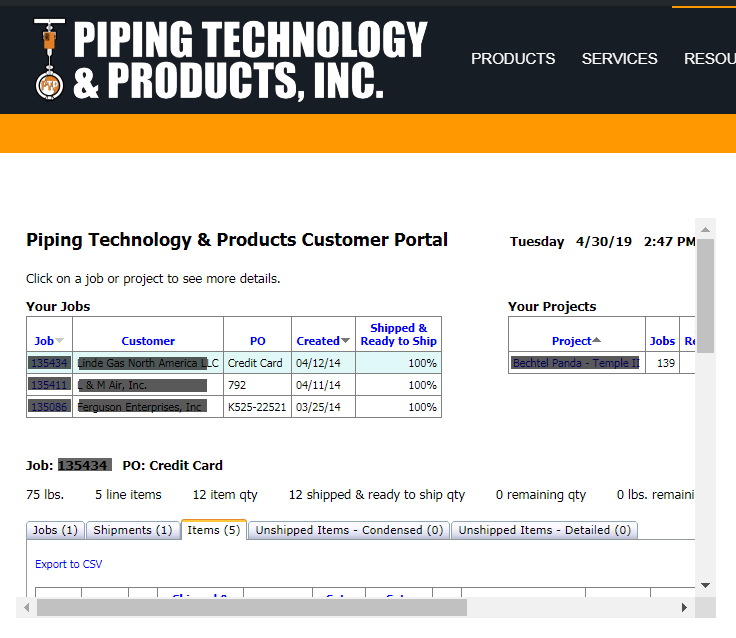

- Manage By Job – every job is easily viewable with a detailed view of status. Figure 3 shows an example of the visibility we have into every order. This is also the same visibility that customers have via the customer portal.

Figure 3 – Sample Job Status Available via Customer Portal

- Manage By Critical Path Operation – PT&P can view backlog, average daily production, and staffing by 50+ detailed operations across all of the production. This allows us to constantly identify bottlenecks and move resources to the most backlogged operation.

- Manage By Short Lead Time Orders – PT&P maintains an entire section of production for short lead-time, smaller volume orders. These orders are delivered within 2 weeks and often times within 48 hours.

- Manage By Product – Because of our scale, we maintain a specialized area of production for a number of products including Expansion Joints, Variables, Constants, Struts, Sway Braces, Pre-Insulated Supports, and Slide Plates. We are able to assess production by product to see how each of these operations are performing.

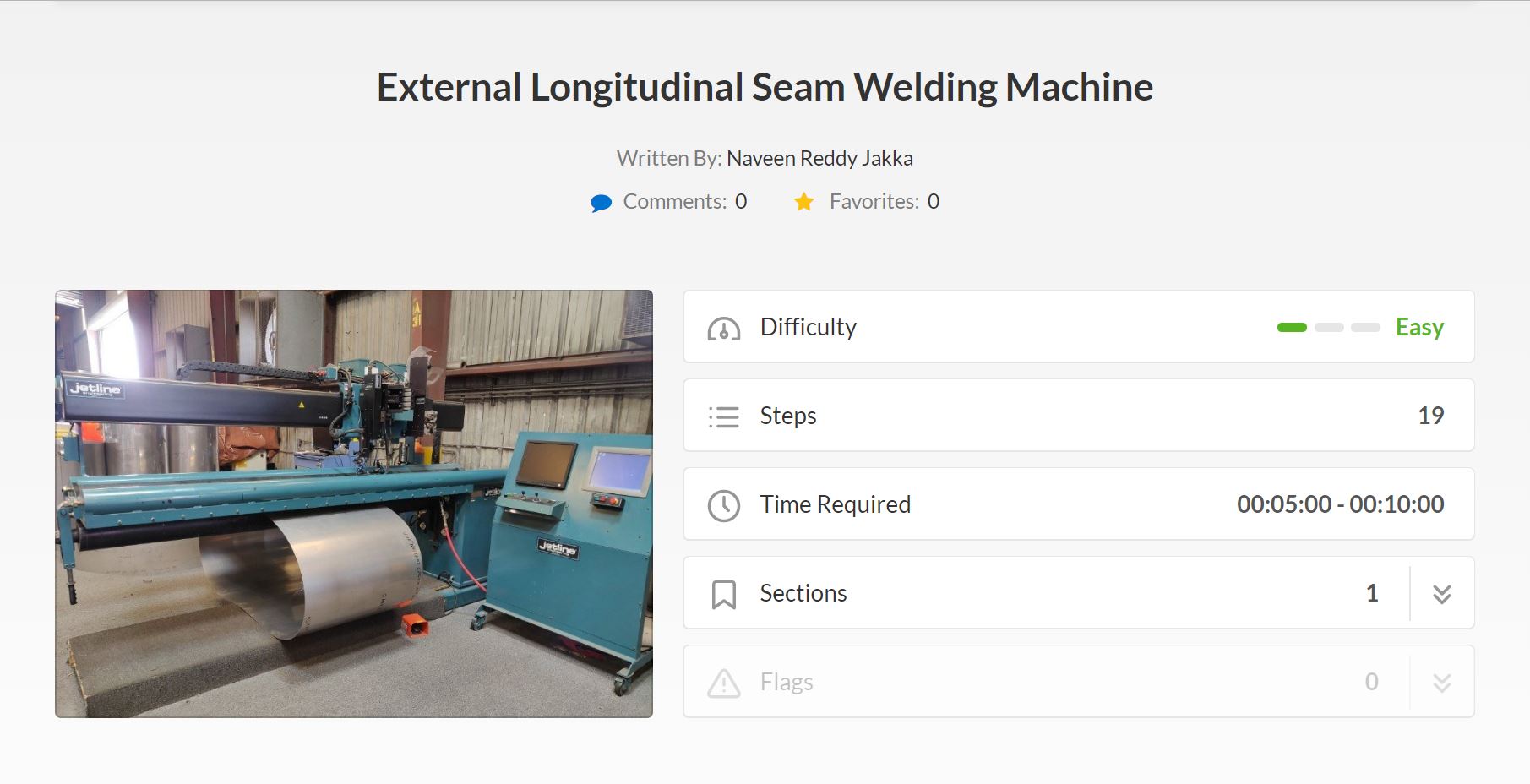

- Work Instructions Software – One of the most difficult aspects of mass customization is how to deal with “tribal” knowledge. In a steel fabrication operation, high degrees of individual knowledge is relied upon for production. In a Mass Production operation, flexibility is eliminated in order to reduce dependence on specialized individual knowledge. PT&P has taken a different approach. It encapsulates complex operations into its Work Instructions Software. The challenge with complex operations is all of the “edge” cases that require “non-intuitive” procedures. For example on our Automatic Long Seam welder in the Expansion Joint operation, sheet metal must be measured as the mill tolerance is not tight enough to specify the program to be used on the welder (e.g. there is a different program for 18 Gauge vs 17 Gauge).

Figure 4 – Sample Work Instructions Software

-

- Partnerships with Houston Colleges – PT&P has established partnerships with key colleges throughout Houston. This allows us to maintain even the most scarce skills within our production operation. PT&P has an unusually deep commitment to learning and education with our founder serving on the Board of Regents of the University of Houston.

- Automation – PT&P’s scale has allowed it to invest in automation which both increases volume and quality. Automated Machinery includes CNC Plasmas, CNC Rolls, CNC Mills, Robotic Welding, Automatic Saws, Automatic Long Seam Welding, and High Volume Foam Pouring.

- Product Specialization – PT&P uses scale across products where appropriate but also has specialized products for some aspects of key products including Expansion Joints, Variables, Constants, Struts, Sway Braces, Snubbers, and Pre-Insulated Supports.

- Growth Plans for Key Skills – anyone with a welding background could tell you that welding carbon steel plate is a piece of cake compared to welding thin gauge Inconel. We start our welders working with carbon steel plate and structure and allow those who show the desire and skills to grow into the higher-skilled areas of welding.

- Management of Material Contamination – PT&P has specific procedures in place to ensure the material remains separated to avoid contamination such as Carbon Steel contaminating Stainless. The combination of material contamination management and skill level required for thin gauge Super Alloys is one of the major reasons PT&P is the ONLY major Pipe Support manufacturer that also manufactures Expansion Joints.

The Benefit for our Customers: Always the Best Solution

Mass Production companies and Steel Fabricators will by their nature be limited in the solutions they can offer. This means they will be tempted to “force fit” customers into their capabilities. The following are just some of the options that PT&P offers with ALL of its products:

- Schedule – approximately 15% of PT&P production is for short lead-time orders in 2 weeks or less with some of these even being less than 24 hours from order to delivery.

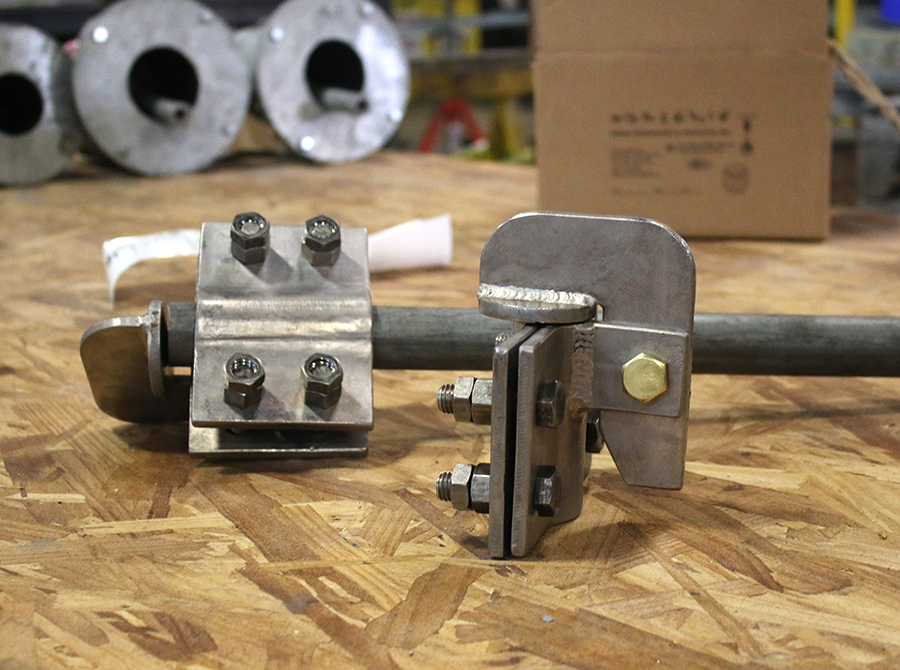

- Material/Unusual Environments – one of the biggest advantages PT&P offers is that it has engineering and production skills to work with almost any type of steel or alloy. In our Expansion Joint operation, we work daily with Stainless Steel and Super Alloys including Monel 400, Inconel, Hastelloy, and INCOLOY®. For example, a customer recently asked us about a Paint over Galvanizing finish for plant struggling with a Caustic Environment and we educated them on the range of options offered by PT&P including an all stainless option along with the ability to even move to Super Alloys. In this case, the customer was supporting Nickel 200 piping which costs over $10/pound with a Variable made of carbon steel which costs under $1 per pound and was failing every 2-3 years.

Figure 5 – Monel 400 Clamps

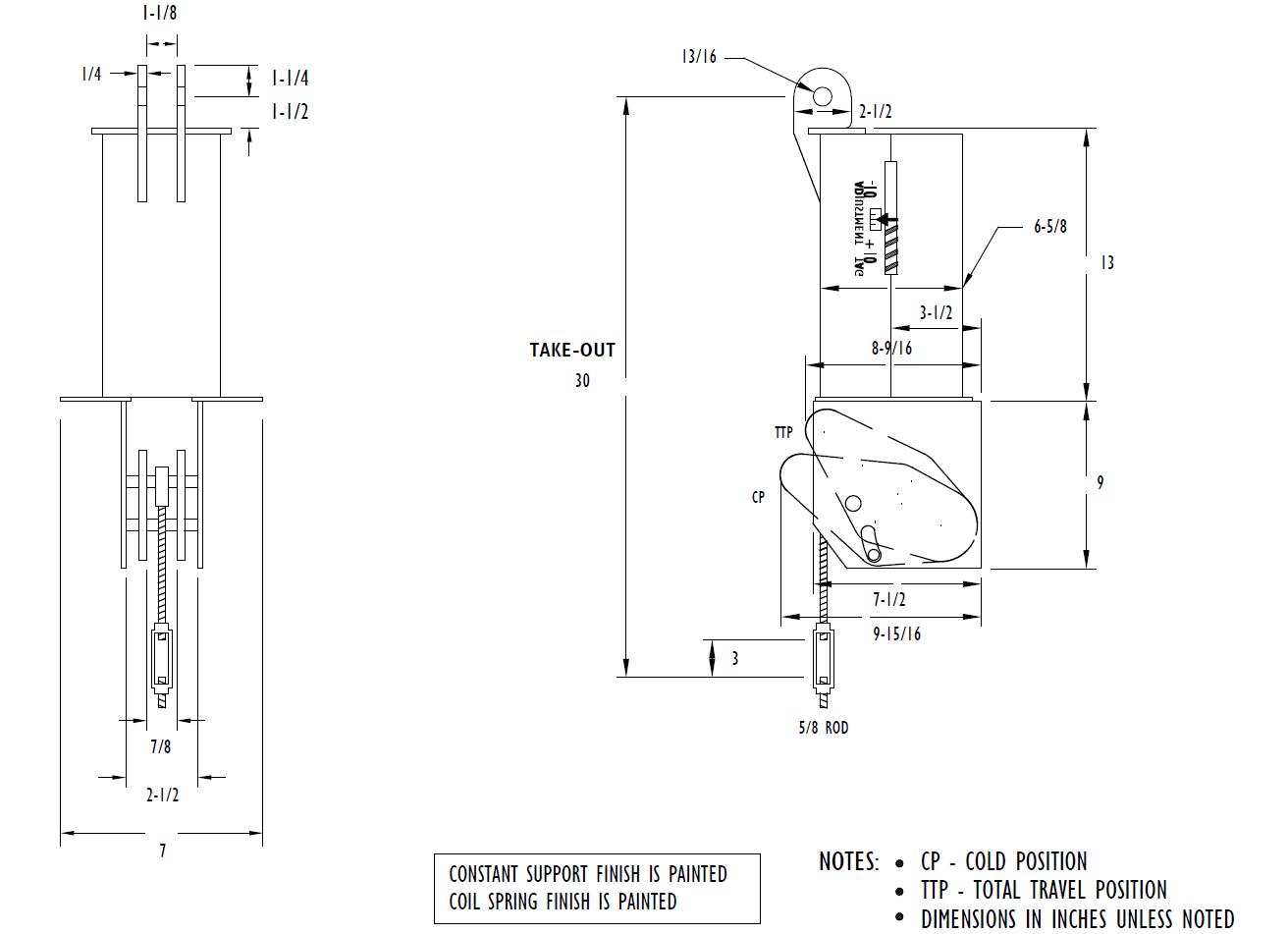

- Space Constraints/Size – PT&P can engineer to any dimensions feasible including the world’s smallest Constant Spring Hanger Designs. If there are challenging space requirements, PT&P can engineer the most efficient solution possible. Figure 6 shows a Nano Constant Design for 750-pound load and 77″ of movement. The overall dimensions of the Frame and Cam are 227″ x 7″ x 9-15/167″. This means PT&P is supporting over 700 pounds and 7″ of movement in with a Constant Hanger that is only 0.89 Cubic Feet!

Figure 6 – Nano Constant Design for 750 Pound Load and 7″ Movement

- Challenging Load Requirements – PT&P invented the Big Ton in 1980 which placed springs in series in order to accommodate larger loads. We have engineered solutions up to 1M pounds of load including complete FEA analysis.

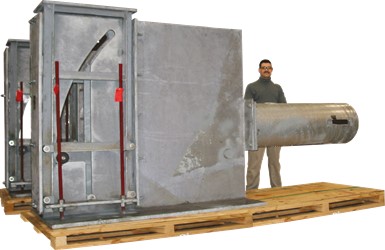

Figure 7 – PT&P 600,000 lb. Load Mega Ton Spring Support with Bronzphite® Slide Plates

- Movement – PT&P has engineered designs across its products for larger more challenging movement requirements. For example, Figure 8 shows a Constant that was designed and produced to support 46″ of movement for a Geothermal plant in Hawaii.

Figure 8 – Constant Load Hanger for 46″ of Movement