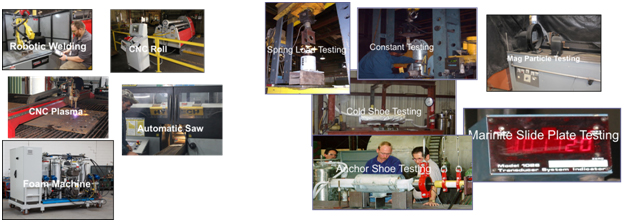

The advantage of scale is that it has allowed us to invest in automation and specialization. This includes:

|

|

Figure 1 – PT&P Key Machinery

Beyond the investment in automation and testing, scale has allowed PT&P to set up it’s manufacturing with a much higher degree of specialization than a small scale steel fabricator. Key departments in PT&P Manufacturing include:

|

|

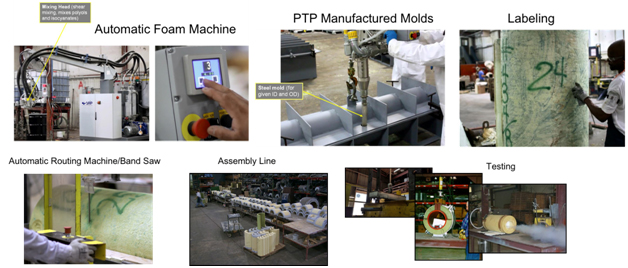

Figure 2 shows an example of how scale impacts the operation of one of our departments. PT&P’s Foam department is configured with the following:

- High Volume Automatic Foam Pouring Machines

- Molds

- Automatic Band Saws

- Labeling and Inventory System

- Assembly Line with Testing

PT&P’s scale allows us to make investments in equipment that produces consistency and allows us to scale up our production quickly. We recently had an inspector from a large EPC visit our operation. Her comment to us was that our operation was far different from others she had visited where they were using buckets as part of their foam pouring process.

Figure 2 – PT&P Foam Department