Clevis Hangers

A clevis hanger is a pipe attachment providing vertical adjustment, consisting of a clevis type top bolted to a formed steel bottom strap. They are recommended for the suspension of non-insulated, stationary pipe lines.

Ammonia Plant

Chemical Plant

Clean Fuels

Commercial

Electric Plant

Energy Facility

Ethylene Plant

LLDPE Chemical Plant

LNG Plant

MTBE Plant

Natural Gas Combined Cycle Facility

Natural Gas Processing & Separation

Oil Refinery

Oil Sand Mine

Paper Manufacturer

See All

A trapeze hanger is a support assembly consisting of parallel vertical rods which are suspended from a structure and connected ...Continue Reading

More FAQs…

GENERAL DIMENSIONS & SPECIFICATIONS

- Fig. 83: Adjustable Clevis Hanger

- Fig. 89: Clevis Hanger for Insulated Lines

- Fig. 195: Roller Hanger

- Fig. 200: Trapeze Roller Hanger

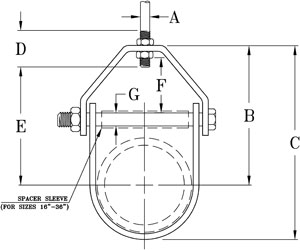

Fig. 83: Adjustable Clevis Hanger

SIZE RANGE: 1/2 inches thru 30 inches

MATERIAL: Carbon steel

FINISH: Black or galvanized: furnished galvanized unless otherwise specified.

SERVICE: Recommended for the suspension of non-insulated, stationary pipe lines.

MAX. TEMP: 650°F.

FEATURES: Designed with the yoke on outside of lower U-Strap so the yoke cannot slide toward the center of the bolt, thus bending of the bolt is minimized. Spacer sleeve used for size 16” thru 36”.

COMPONENTS: Top yoke, bottom strap, and bolt or stud with nut-assembled.

INSTALLATION: Hanger load nut ABOVE clevis must be tightened securely to assure proper hanger performance.

ORDERING: Specify figure number, pipe size, description and finish.

NOTE: Punched forming holes may be present on certain sizes of this clevis hanger. These holes are solely for the purpose of manufacturing and do not affect the structural integrity or load carrying capacities of these hangers.

| PIPE SIZE | MAX. RECOM. LOAD, lbs. | WEIGHT (APPROX.) lbs. per 100 | SIZE OF STEEL | A | B | C | D | E | ADJUSTMENT | G | |

| Upper | Lower | F | |||||||||

| 1/2 | 730 | 34 | 1/8 x 1 | 1/8 x 1 | 3/8 | 1 11/16 | 2 1/8 | 2 1/2 | 7/8 | 7/16 | 1/4 |

| 3/4 | 730 | 39 | 1/8 x 1 | 1/8 x 1 | 3/8 | 1 7/8 | 2 7/16 | 2 1/2 | 1 | 1/2 | 1/4 |

| 1 | 730 | 44 | 1/8 x 1 | 1/8 x 1 | 3/8 | 2 1/8 | 2 13/16 | 2 1/2 | 1 1/4 | 5/8 | 1/4 |

| 1 1/4 | 730 | 45 | 1/8 x 1 | 1/8 x 1 | 3/8 | 2 9/16 | 3 7/16 | 2 1/2 | 1 3/4 | 7/8 | 1/4 |

| 1 1/2 | 730 | 55 | 1/8 x 1 | 1/8 x 1 | 3/8 | 3 | 4 | 2 1/2 | 2 1/8 | 1 1/16 | 1/4 |

| 2 | 730 | 61 | 1/8 x 1 | 1/8 x 1 | 3/8 | 3 11/16 | 4 7/8 | 2 1/2 | 2 15/16 | 1 5/8 | 1/4 |

| 2 1/2 | 1350 | 140 | 3/16 x 1 1/4 | 3/16 x 1 1/4 | 1/2 | 4 11/16 | 6 1/8 | 3 | 3 13/16 | 2 | 3/8 |

| 3 | 1350 | 152 | 3/16 x 1 1/4 | 3/16 x 1 1/4 | 1/2 | 4 3/4 | 6 9/16 | 3 | 3 7/8 | 1 3/4 | 3/8 |

| 3 1/2 | 1350 | 170 | 3/16 x 1 1/4 | 3/16 x 1 1/4 | 1/2 | 4 15/16 | 6 15/16 | 3 | 4 1/16 | 1 3/4 | 3/8 |

| 4 | 1430 | 213 | 1/4 x 1 1/4 | 3/16 x 1 1/4 | 5/8 | 5 9/16 | 7 13/16 | 3 1/2 | 4 1/2 | 1 15/16 | 3/8 |

| 5 | 1430 | 244 | 1/4 x 1 1/4 | 3/16 x 1 1/4 | 5/8 | 6 3/16 | 9 | 3 1/2 | 5 1/8 | 1 3/4 | 1/2 |

| 6 | 1940 | 357 | 1/4 x 1 1/2 | 3/16 x 1 1/2 | 3/4 | 6 15/16 | 10 1/8 | 4 | 5 5/8 | 1 7/8 | 1/2 |

| 8 | 2000 | 497 | 1/4 x 1 3/4 | 3/16 x 1 3/4 | 7/8 | 8 3/8 | 12 5/8 | 4 1/4 | 7 | 2 1/8 | 5/8 |

| 10 | 3600 | 880 | 3/8 x 1 3/4 | 1/4 x 1 3/4 | 7/8 | 9 7/8 | 15 1/4 | 4 1/2 | 8 3/8 | 2 1/4 | 3/4 |

| 12 | 3800 | 1142 | 3/8 x 2 | 1/4 x 2 | 7/8 | 11 1/2 | 18 | 4 1/2 | 10 3/16 | 3 | 3/4 |

| 14 | 4200 | 1484 | 1/2 x 2 | 1/4 x 2 | 1 | 12 7/16 | 19 7/16 | 5 1/4 | 10 13/16 | 2 15/16 | 7/8 |

| 16 | 4600 | 2104 | 1/2 x 2 1/2 | 1/4 x 2 1/2 | 1 | 14 1/16 | 22 1/16 | 6 | 12 7/16 | 2 5/8 | 1 |

| 18 | 4800 | 2442 | 1/2 x 2 1/2 | 1/4 x 2 1/2 | 1 | 15 1/2 | 24 3/4 | 6 1/2 | 13 15/16 | 3 7/8 | 1 1/8 |

| 20 | 4800 | 4265 | 3/4 x 3 | 3/8 x 3 | 1 1/4 | 17 1/4 | 27 3/8 | 7 | 14 7/16 | 4 | 1 1/4 |

| 24 | 4800 | 4853 | 3/4 x 3 | 3/8 x 3 | 1 1/4 | 19 5/8 | 31 5/8 | 7 1/2 | 17 1/2 | 4 1/4 | 1 1/4 |

| 30 | 6000 | 6964 | 1 x 3 | 3/8 x 3 | 1 1/4 | 24 1/8 | 39 1/8 | 8 1/4 | 21 7/8 | 5 | 1 1/4 |

| 36 | | 7716 | 1 x 3 | 3/8 x 3 | 1 1/4 | 27 1/8 | 46 3/16 | 8 1/4 | 25 1/2 | 5 1/2 | 1 1/4 |

Fig. 89: Clevis Hanger for Insulated Lines

MATERIAL: Carbon steel

FINISH: Black

FUNCTION:Equivalent to Fig. 83, except bottom has been lengthened to allow covering without interfering with the bolt.

APPROVALS:Conforms to Federal Specification WW-H-171-E, Type 1 and Manufacturers Standardization Society SP-69, Type 1

COMPONENTS: Top yoke, bottom strap, and bolt or stud with nut-assembled.

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. | APPROX. WEIGHT | SIZE OF STEEL | ADJUST. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LOAD, lbs. | lbs. per 100 | upper | lower | A | B | C | D | E | F | G | H | |

| 1/2 | 730 | 44 | 1/8 x 1 | 1/8 x 1 | 3/8 | 3 5/8 | 4 3/16 | 2 1/2 | 2 7/8 | 1/2 | 1/4 | 2 |

| 3/4 | 730 | 51 | 1/8 x 1 | 1/8 x 1 | 3/8 | 3 5/8 | 4 1/4 | 2 1/2 | 2 7/8 | 1/2 | 1/4 | 2 |

| 1 | 730 | 58 | 1/8 x 1 | 1/8 x 1 | 3/8 | 4 | 4 11/16 | 2 1/2 | 3 1/4 | 5/8 | 1/4 | 2 |

| 1 1/4 | 730 | 64 | 1/8 x 1 | 1/8 x 1 | 3/8 | 4 7/16 | 5 1/4 | 2 1/2 | 3 5/8 | 7/8 | 1/4 | 2 |

| 1 1/2 | 730 | 72 | 1/8 x 1 | 1/8 x 1 | 3/8 | 4 3/4 | 5 3/4 | 2 1/2 | 4 1/16 | 1 1/16 | 1/4 | 2 |

| 2 | 730 | 85 | 1/8 x 1 | 1/8 x 1 | 3/8 | 7 7/16 | 8 11/16 | 2 1/2 | 6 1/2 | 1 5/8 | 1/4 | 4 |

| 2 1/2 | 1350 | 191 | 3/16 x 1 1/4 | 3/16 x 1 1/4 | 1/2 | 8 7/16 | 9 15/16 | 3 | 7 1/2 | 2 | 3/8 | 4 |

| 3 | 1350 | 201 | 3/16 x 1 1/4 | 3/16 x 1 1/4 | 1/2 | 8 5/8 | 10 5/16 | 3 | 7 9/16 | 1 3/4 | 3/8 | 4 |

| 3 1/2 | 1350 | 210 | 3/16 x 1 1/4 | 3/16 x 1 1/4 | 1/2 | 8 11/16 | 10 3/4 | 3 | 7 3/4 | 1 3/4 | 3/8 | 4 |

| 4 | 1430 | 247 | 1/4 x 1 1/4 | 3/16 x 1 1/4 | 5/8 | 9 3/8 | 11 5/8 | 3 1/2 | 8 3/16 | 1 15/16 | 3/8 | 4 |

| 5 | 1430 | 309 | 1/4 x 1 1/4 | 3/16 x 1 1/4 | 5/8 | 9 7/8 | 12 5/8 | 3 1/2 | 8 3/4 | 1 3/4 | 1/2 | 4 |

| 6 | 1940 | 337 | 1/4 x 1 1/2 | 3/16 x 1 1/2 | 3/4 | 10 5/8 | 14 | 4 | 9 3/8 | 1 7/8 | 1/2 | 4 |

| 8 | 2000 | 673 | 1/4 x 1 3/4 | 3/16 x 1 3/4 | 7/8 | 12 3/8 | 16 3/4 | 4 1/4 | 11 | 2 | 5/8 | 4 |

| 10 | 3600 | 1102 | 3/8 x 1 3/4 | 1/4 x 1 3/4 | 7/8 | 13 3/4 | 19 3/16 | 4 1/2 | 12 1/4 | 2 1/8 | 3/4 | 4 |

| 12 | 3800 | 1382 | 3/8 x 2 | 1/4 x 2 | 7/8 | 15 1/8 | 21 9/16 | 4 1/2 | 13 5/8 | 2 7/16 | 3/4 | 4 |

Fig. 195: Roller Hanger

MATERIAL: Cast iron roll, carbon steel yoke, roll rod, and hex nuts.

SERVICE: For suspension of pipe from a single rod where horizontal movement may occur because of expansion or contraction.

HOW TO SIZE: If the roll is to support bare pipe, select the size directly from the nominal pipe size (see table below).

ORDERING: Specify figure number, pipe size, description and finish.

| NOMINAL PIPE SIZE | MAX. O.D. OF COVERING | MAX. RECOM. LOAD, lb. | APPROX. WEIGHT (lb. per 100) | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 3 | 225 | 170 | 1/2 | 5 3/4 | 3 1/4 | 1 15/16 | 2 7/8 | 1/2 | 3/16 x 1 | 1 11/16 |

| 3 | 3 5/8 | 310 | 220 | 1/2 | 6 3/8 | 3 7/8 | 2 1/4 | 3 1/8 | 1/2 | 1/4 x 1 | 1 5/8 |

| 3 1/2 | 4 1/8 | 390 | 253 | 1/2 | 7 | 4 3/8 | 2 9/16 | 3 1/2 | 1/2 | 1/4 x 1 1/4 | 1 11/16 |

| 4 | 4 11/16 | 475 | 321 | 5/8 | 7 9/16 | 4 15/16 | 2 13/16 | 3 5/8 | 1/2 | 1/4 x 1 1/2 | 1 5/8 |

| 5 | 5 3/4 | 685 | 627 | 5/8 | 9 1/8 | 6 | 3 7/16 | 4 1/2 | 5/8 | 3/8 x 1 3/4 | 1 15/16 |

| 6 | 6 7/8 | 780 | 927 | 3/4 | 10 5/16 | 7 1/8 | 4 | 5 | 3/4 | 3/8 x 2 | 1 7/8 |

| 8 | 9 | 780 | 1454 | 7/8 | 12 11/16 | 9 1/4 | 5 1/8 | 6 1/8 | 7/8 | 3/8 x 2 1/2 | 2 |

| 10 | 11 | 965 | 1880 | 7/8 | 15 1/16 | 11 1/4 | 6 3/8 | 7 1/4 | 7/8 | 3/8 x 2 1/2 | 2 1/16 |

| 12 | 13 | 1200 | 2774 | 7/8 | 17 7/16 | 13 1/4 | 7 7/16 | 8 3/8 | 1 | 1/2 x 2 1/2 | 2 1/4 |

| 14 | 14 1/4 | 1200 | 3913 | 1 | 18 7/8 | 14 1/2 | 8 3/8 | 8 3/4 | 1 1/8 | 1/2 x 2 1/2 | 2 |

| 16 | 16 1/4 | 1200 | 4905 | 1 | 20 13/16 | 16 1/2 | 9 3/8 | 9 11/16 | 1 1/4 | 1/2 x 2 1/2 | 1 15/16 |

| 18 | 18 1/4 | 1400 | 5780 | 1 1/8 | 23 3/4 | 18 1/2 | 10 7/16 | 11 7/16 | 1 1/4 | 1/2 x 3 | 2 11/16 |

| 20 | 20 1/4 | 1600 | 7594 | 1 1/4 | 26 | 20 1/2 | 11 5/8 | 12 1/4 | 1 3/8 | 5/8 x 3 | 2 1/2 |

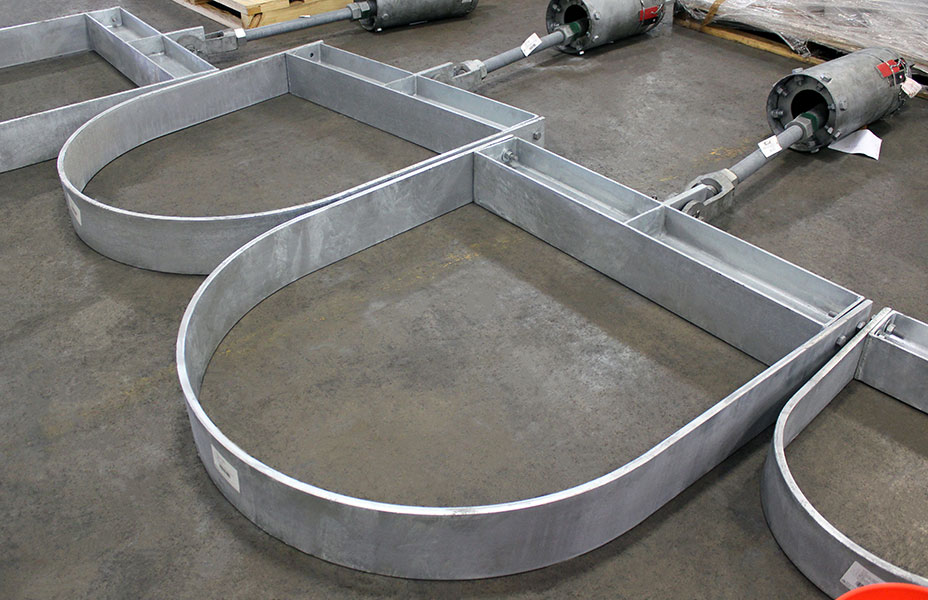

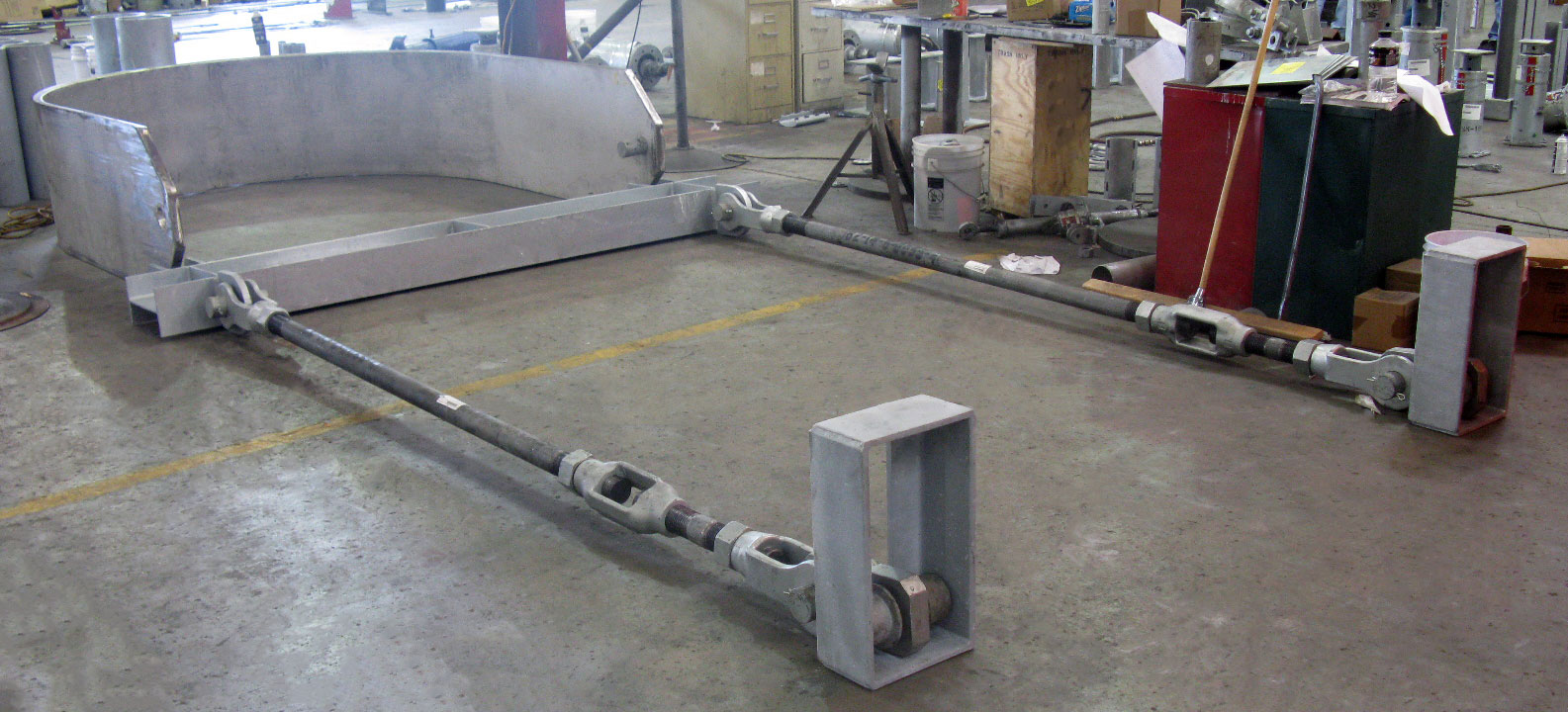

Fig. 200: Trapeze Roller Hanger

MATERIAL: Cast iron roll and sockets; steel roll rod.

SERVICE: For suspension of pipe from two rods where longitudinal movement due to expansion or contraction may occur.

ADJUSTMENT: Adjustment socket permits vertical adjustment at the roll.

HOW TO SIZE:

1. If the roll is to support non-insulated pipe, select the size directly from nominal pipe size.

2. If used with pipe covering protection saddle, see Fig, 184, 185, 186, 187, 188, and 189 for size of pipe roll.

3. If roll is to support covered pipe, select the nominal pipe size (column 1) which corresponds to the O.D. of covering and saddle (column 2).

ORDERING: Specify figure number, nominal pipe size, description and finish.

| NOMINAL PIPE SIZE | MAX. O.D. OF COVERING | ADJUSTED SOCKET No. | MAX. RECOM.SAFE LOAD (lb.) | APPROX. WEIGHT (lb. per 100) | A | B | C | D | E | F | G | H | J |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1 — 3/8 | 600 | 45 | 4 1/8 | 3 | 1 1/2 | 1 | 3/4 | 3/8 | 3/8 | 1 1/16 | 9/16 |

| 1 1/4 | 2 1/2 | 1 — 3/8 | 600 | 48 | 4 1/2 | 3 3/8 | 1 7/8 | 1 1/16 | 3/4 | 3/8 | 3/8 | 1 1/4 | 9/16 |

| 1 1/2 | 2 3/4 | 1 — 3/8 | 600 | 51 | 4 3/4 | 3 5/8 | 2 1/8 | 1 1/8 | 3/4 | 3/8 | 3/8 | 1 3/8 | 9/16 |

| 2 | 3 1/4 | 1 — 3/8 | 600 | 57 | 5 1/4 | 4 1/8 | 2 5/8 | 1 3/16 | 3/4 | 3/8 | 3/8 | 1 5/8 | 9/16 |

| 2 1/2 | 3 3/4 | 2 — 1/2 | 660 | 100 | 6 1/4 | 4 7/8 | 3 1/8 | 1 3/8 | 7/8 | 1/2 | 1/2 | 1 15/16 | 11/16 |

| 3 | 4 1/2 | 2 — 1/2 | 700 | 110 | 6 7/8 | 5 1/2 | 3 3/4 | 1 7/16 | 7/8 | 1/2 | 1/2 | 2 1/4 | 11/16 |

| 3 1/2 | 5 | 2 — 1/2 | 750 | 135 | 7 1/2 | 6 1/8 | 4 1/4 | 1 5/8 | 1 | 1/2 | 1/2 | 2 9/16 | 3/4 |

| 3 — 1/2 | 150 | 7 3/4 | 6 1/4 | 5/8 | 3/4 | ||||||||

| 4 | 5 1/2 | 2 — 1/2 | 750 | 150 | 8 | 6 5/8 | 4 3/4 | 1 3/4 | 1 | 1/2 | 1/2 | 2 13/16 | 3/4 |

| 3 — 1/2 | 165 | 8 1/4 | 6 3/4 | 5/8 | 3/4 | ||||||||

| 5 | 7 | 2 — 5/8 | 750 | 226 | 9 7/16 | 8 1/16 | 5 13/16 | 2 | 1 1/8 | 5/8 | 1/2 | 3 7/16 | 13/16 |

| 3 — 5/8 | 257 | 9 11/16 | 5/8 | 7/8 | |||||||||

| 6 | 8 1/4 | 2 — 3/4 | 1070 | 378 | 10 15/16 | 9 9/16 | 6 7/8 | 2 5/16 | 1 1/4 | 3/4 | 1/2 | 4 | 7/8 |

| 3 — 3/4 | 416 | 11 3/16 | 5/8 | 1 | |||||||||

| 4 — 3/4 | 445 | 11 7/16 | 3/4 | 1 | |||||||||

| 8 | 10 1/2 | 2 — 7/8 | 1350 | 585 | 13 5/16 | 11 15/16 | 8 7/8 | 2 13/16 | 1 1/2 | 7/8 | 1/2 | 5 1/8 | 15/16 |

| 3 — 7/8 | 625 | 13 9/16 | 5/8 | 1 1/16 | |||||||||

| 4 — 7/8 | 690 | 13 13/16 | 3/4 | 1 3/16 | |||||||||

| 5 — 7/8 | 715 | 14 1/16 | 7/8 | 1 1/8 | |||||||||

| 10 | 12 3/4 | 2 — 7/8 | 1730 | 838 | 15 7/16 | 14 1/16 | 11 | 3 3/8 | 1 3/4 | 7/8 | 1/2 | 6 3/8 | 15/16 |

| 3 — 7/8 | 862 | 15 11/16 | 5/8 | 1 1/16 | |||||||||

| 4 — 7/8 | 920 | 15 15/16 | 3/4 | 1 3/16 | |||||||||

| 5 — 7/8 | 950 | 16 3/16 | 7/8 | 1 1/8 | |||||||||

| 12 | 14 3/4 | 3 — 1 | 2400 | 1465 | 17 7/16 | 15 13/16 | 12 1/2 | 3 7/8 | 2 | 1 | 5/8 | 7 7/16 | 1 1/8 |

| 4 — 1 | 1525 | 17 11/16 | 3/4 | 1 1/4 | |||||||||

| 5 — 1 | 1590 | 17 15/16 | 7/8 | 1 1/4 | |||||||||

| 14 | 16 1/4 | 5 — 1 1/8 | 3130 | 2360 | 19 7/8 | 17 3/4 | 14 1/4 | 4 5/8 | 2 1/2 | 1 1/8 | 7/8 | 8 3/8 | 1 7/16 |

| 6 — 1 1/8 | 2425 | 20 1/8 | 1 | 1 3/8 | |||||||||

| 16 | 18 | 5 — 1 1/4 | 3970 | 3080 | 21 7/8 | 19 3/4 | 16 1/4 | 5 | 2 5/8 | 1 1/4 | 7/8 | 9 7/16 | 1 1/2 |

| 6 — 1 1/4 | 3185 | 22 1/8 | 1 | 1 1/2 | |||||||||

| 7 — 1 1/4 | 3260 | 22 3/8 | 1 1/8 | 1 1/2 | |||||||||

| 18 | 20 1/4 | 5 — 1 1/4 | 4200 | 3370 | 24 | 21 7/8 | 18 1/4 | 5 7/16 | 2 3/4 | 1 1/4 | 7/8 | 10 1/2 | 1 1/2 |

| 6 — 1 1/4 | 3475 | 24 1/4 | 1 | 1 1/2 | |||||||||

| 7 — 1 1/4 | 3550 | 24 1/2 | 1 1/8 | 1 1/2 | |||||||||

| 20 | 22 1/2 | 8 — 1 3/8 | 4550 | 4700 | 27 1/4 | 24 1/4 | 20 1/4 | 6 | 3 | 1 1/4 | 1 1/4 | 11 5/8 | 1 5/8 |

| 24 | 26 1/2 | 6 — 1 1/2 | 6160 | 7255 | 31 | 28 5/8 | 24 1/4 | 7 3/16 | 3 5/8 | 1 1/2 | 1 | 14 | 1 13/16 |

| 7 — 1 1/2 | 7365 | 31 1/4 | 1 1/8 | 1 15/16 | |||||||||

| 8 — 1 1/2 | 7500 | 31 5/8 | 1 1/4 | 2 1/16 | |||||||||

| 9 — 1 1/2 | 7630 | 32 1/8 | 1 1/2 | 1 3/4 | |||||||||

| 30 | 32 1/2 | 8 — 1 7/8 | 7290 | 12690 | 38 1/2 | 35 1/2 | 30 1/4 | 8 15/16 | 4 1/2 | 1 3/4 | 1 1/4 | 17 7/16 | 2 1/4 |

| 9 — 1 7/8 | 12990 | 39 | 1 1/2 | 2 7/16 | |||||||||

| 10 — 1 7/8 | 13400 | 39 7/8 | 1 7/8 | 2 1/8 |

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});