Pipe Saddles & Coverings

A pipe saddle is a structure consisting of a saddle and integral base that is used to support the pipe by transmitting the load or forces to the adjacent structure.

Acid Plants

Ammonia Plant

Chemical Plant

Clean Fuels

Cogeneration Plant

Cold / Cryogenc Service

Commercial

Electric Plant

Energy Facility

Ethylene Plant

Heat Recovery Steam Generation Plant

Hospital

LLDPE Chemical Plant

LNG Plant

MTBE Plant

See All

A saddle support is a support consisting of a stanchion that utilizes a curved section for cradling the pipe. Adjustable ...Continue Reading

A pipe saddle is a structure consisting of a saddle and integral base that is used to support the pipe ...Continue Reading

The pipe saddle size will be dependent upon the pipe diameter and the thickness of the insulation. 42″ Large Bore ...Continue Reading

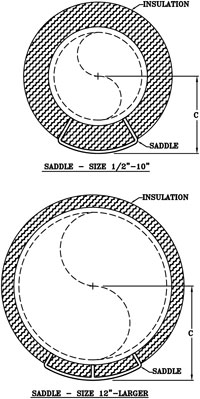

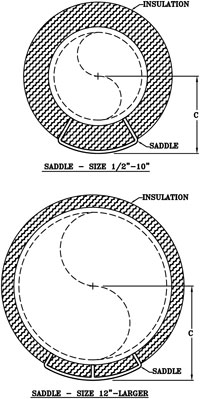

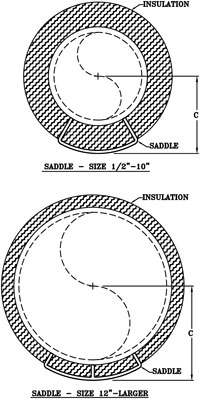

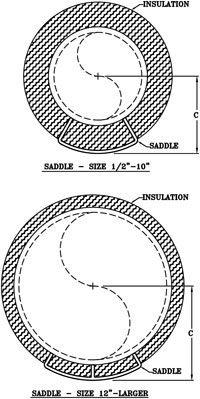

In order to determine the appropriate insulation covering saddle, one would measure the O.D. of the pipe and insulation together ...Continue Reading

For saddle supports that do not require welding, the installation process would involve locating the saddle support in the correct ...Continue Reading

More FAQs…

- Fig. 46: Adjustable Pipe Saddle Support

- Fig. 48: Pipe Saddle Support with U-Bolt

- Fig. 183: Pipe Insulation Protection Shield

- Fig. 184: Pipe Covering Saddle for 1" Insulation

- Fig. 185: Pipe Covering Saddle for 1 1/2" Insulation

- Fig. 186: Pipe Covering Saddle for 2" Insulation

- Fig. 187: Pipe Covering Saddle for 2 1/2" Insulation

- Fig. 188: Pipe Covering Saddle for 3" Insulation

- Fig. 189: Pipe Covering Saddle for 4" Insulation

- Fig. 2000: Heavy Duty Pipe Saddles

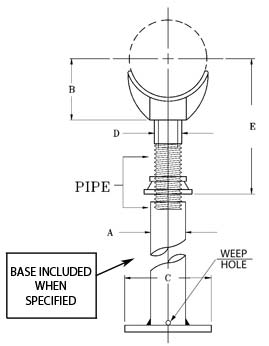

Fig. 46: Adjustable Pipe Saddle Support

MATERIAL: Carbon steel saddle, locknut nipple, and special cast iron reducer, assembled. Base included when specified.

SERVICE: Stanchion type support where vertical adjustment is required.

INSTALLATION: Adjustment is obtained by turning the lock-nut nipple, the lower end of the nipple, and coupling during adjustment.

ORDERING: Specify figure number, pipe size, description and finish.

*Max Load varies based on overall height

| PIPE SIZE | APPROX. WEIGHT lbs. per 100 | A | B | C | D | E | MAX LOAD* | ||

| Complete | Saddle Only | Square | Min. | Max. | |||||

| 2 1/2 | 900 | 480 | 2 1/2 | 3 1/2 | 9 | 1 1/2 | 8 | 13 | 2,000 |

| 3 | 920 | 500 | 2 1/2 | 3 3/4 | 9 | 1 1/2 | 8 1/4 | 13 1/4 | 2,000 |

| 3 1/2 | 940 | 520 | 2 1/2 | 4 | 9 | 1 1/2 | 8 1/2 | 13 1/2 | 2,000 |

| 4 | 1500 | 760 | 3 | 4 1/4 | 9 | 2 1/2 | 9 1/4 | 14 | 3,800 |

| 5 | 1665 | 925 | 3 | 4 7/8 | 9 | 2 1/2 | 10 | 14 3/4 | 3,800 |

| 6 | 1765 | 1025 | 3 | 5 1/2 | 9 | 2 1/2 | 10 1/2 | 15 1/4 | 3,800 |

| 8 | 2020 | 1280 | 3 | 6 7/8 | 9 | 2 1/2 | 11 3/4 | 16 1/2 | 3,800 |

| 10 | 2515 | 1775 | 3 | 8 1/2 | 9 | 2 1/2 | 13 1/2 | 18 1/4 | 3,800 |

| 12 | 2900 | 2160 | 3 | 9 15/16 | 9 | 2 1/2 | 15 | 19 3/4 | 3,800 |

| 14 | 4920 | 3800 | 4 | 10 15/16 | 11 | 3 | 16 1/4 | 20 3/4 | 5,300 |

| 16 | 5320 | 4200 | 4 | 12 3/8 | 11 | 3 | 17 3/4 | 22 1/4 | 5,300 |

| 18 | 7080 | 5100 | 6 | 13 7/8 | 13 1/2 | 3 1/2 | 19 1/2 | 24 | 6,700 |

| 20 | 10480 | 8500 | 6 | 15 3/8 | 13 1/2 | 3 1/2 | 21 | 25 1/2 | 6,700 |

| 24 | 13000 | 11000 | 6 | 17 15/16 | 13 1/2 | 4 | 23 3/4 | 28 1/4 | 7,300 |

| 30 | 17000 | 15000 | 6 | 21 5/16 | 13 1/2 | 4 | 27 | 31 1/2 | 7,300 |

| 32 | 18100 | 16100 | 6 | 22 1/2 | 13 1/2 | 4 | 28 1/4 | 32 3/4 | 7,300 |

| 36 | 24900 | 22900 | 6 | 24 1/2 | 13 1/2 | 4 | 30 1/4 | 34 3/4 | 7,300 |

Fig. 48: Pipe Saddle Support with U-Bolt

MATERIAL: Carbon steel stanchion saddle with steel U-Bolt and nuts.

INSTALLATION:

1. Slip saddle base into riser pipe.

2. If riser pipe and flange are used, flange is drilled for bolting to steel beam or floor.

3. Yoke is attached to saddle after pipe is in place.

ORDERING: Specify figure number, pipe size, description, material and finish.

| PIPE SIZE | APPROX. WEIGHT (lbs. per 100) | A | B | MAX LOAD |

| 4 | 1075 | 3 | 4 3/16 | 3,800 |

| 5 | 1210 | 3 | 4 13/16 | 3,800 |

| 6 | 1270 | 3 | 5 7/16 | 3,800 |

| 8 | 2130 | 3 | 6 15/16 | 3,800 |

| 10 | 2570 | 3 | 8 7/16 | 3,800 |

| 12 | 3120 | 3 | 9 15/16 | 3,800 |

| 14 | 5000 | 4 | 10 15/16 | 5,300 |

| 16 | 5700 | 4 | 12 3/8 | 5,300 |

| 18 | 6400 | 4 | 13 7/8 | 6,700 |

| 20 | 11350 | 6 | 15 3/8 | 6,700 |

| 24 | 13700 | 6 | 17 15/16 | 7,300 |

| 30 | 14650 | 6 | 19 1/8 | 7,300 |

| 32 | 17400 | 8 | 21 5/16 | 7,300 |

| 36 | 26800 | 8 | 24 1/2 | 7,300 |

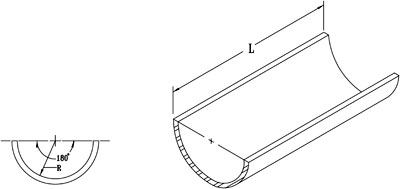

Fig. 183: Pipe Insulation Protection Shield

MATERIAL: Carbon steel

FINISH: Galvanized and black

SIZE RANGE: For use with ½” thru 24” pipe with insulation thickness ½”, 3/4”, 1”, 1 ½” and 2”.

SERVICE: Recommended for outside of foam or fiber glass insulation to preclude crushing of insulation without breaking the vapor barrier.

APPROVALS: Complies with Federal Specification WW-H-171E (Type 41) and Manufacturers Standardization Society SP-69 (Type 40).

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

| Shield Size Selection Table Insulation Thickness (in.) |

|||||

| SIZE | 1/2 | 3/4 | 1 | 1-1/2 | 2 |

| 1/2 | 1A | 1A | — | — | — |

| 3/4 | 1A | 1A | 2A | 4A | 6A |

| 1 | 1A | 2A | 3A | 5A | 7A |

| 1 1/4 | 2A | 3A | 3A | 6A | 7A |

| 1 1/2 | 2A | 3A | 4A | 6A | 7A |

| 2 | 3A | 4A | 5A | 7A | 8A |

| 2 1/2 | 4A | 5A | 6A | 7A | 8A |

| 3 | 5A | 6A | 7A | 8A | 9A |

| 3 1/2 | — | — | 8A | 9A | 10A |

| 4 | — | — | 8A | 9A | 10A |

| 5 | — | — | 9B | 10B | 11B |

| 6 | — | — | 10B | 11B | 12B |

| 8 | — | — | — | 13C | 14C |

| 10 | — | — | 14C | 15C | 16C |

| 12 | — | — | 16C | 17C | 18C |

| 14 | — | — | 17C | 18C | 19C |

| 16 | — | — | 19C | 20C | 21C |

| 18 | — | — | 21C | 22C | 23C |

| 20 | — | — | 23C | 24C | 25C |

| 24 | — | — | 26C | 27C | 28C |

| SHIELD DIMENSION | ||||

| SHIELD SIZE | STOCK SIZE (GAGE ) | APPROX. WEIGHT each | LENGTH L | RADIUS R |

| X1A | 18 | 0.54 | 12 | 0.95 |

| 1A | 18 | 0.69 | 12 | 1.19 |

| 2A | 18 | 0.84 | 12 | 1.44 |

| 3A | 18 | 0.99 | 12 | 1.75 |

| 4A | 18 | 1.1 | 12 | 2.00 |

| 5A | 18 | 1.3 | 12 | 2.25 |

| 6A | 18 | 1.4 | 12 | 2.50 |

| 7A | 18 | 1.6 | 12 | 2.78 |

| 8A | 16 | 1.9 | 12 | 3.32 |

| 9A | 16 | 2.7 | 12 | 3.82 |

| 10A | 16 | 3.1 | 12 | 4.32 |

| 9B | 16 | 4.0 | 18 | 3.82 |

| 10B | 16 | 4.6 | 18 | 4.32 |

| 11B | 16 | 5.1 | 18 | 4.82 |

| 12B | 16 | 5.6 | 18 | 5.38 |

| 13C | 14 | 10.2 | 24 | 5.88 |

| 14C | 14 | 11.1 | 24 | 6.38 |

| 15C | 14 | 11.9 | 24 | 7.00 |

| 16C | 14 | 12.7 | 24 | 7.50 |

| 17C | 14 | 13.6 | 24 | 8.00 |

| 18C | 14 | 14.5 | 24 | 8.50 |

| 19C | 12 | 21.2 | 24 | 9.00 |

| 20C | 12 | 22.4 | 24 | 9.50 |

| 21C | 12 | 23.6 | 24 | 10.00 |

| 22C | 12 | 24.8 | 24 | 10.50 |

| 23C | 12 | 25.9 | 24 | 11.00 |

| 24C | 12 | 27.1 | 24 | 11.50 |

| 25C | 12 | 28.3 | 24 | 12.00 |

| 26C | 12 | 31.0 | 24 | 13.00 |

| 27C | 12 | 31.8 | 24 | 13.50 |

| 28C | 12 | 33.0 | 24 | 14.00 |

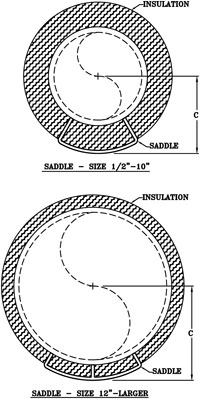

Fig. 184: Pipe Covering Saddle for 1″ Insulation

FINISH: Black, galvanized, or painted.

SERVICE : Designed to keep insulation from crushing and to reduce heat losses.

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

NOTE: All saddles are 12” long with the side edges turned up.

| FIG. 184 - 1″ INSULATION | ||||

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT (lb. per 100) | COVERING THK. | C |

| 3/4 | 1200 | 141 | 7/8 | 1 9/16 |

| 1 | 1200 | 141 | 1 1/16 | 1 7/8 |

| 1 1/4 | 1200 | 141 | 7/8 | 1 7/8 |

| 1 1/2 | 1200 | 151 | 1 | 2 1/8 |

| 2 | 1200 | 167 | 1 1/16 | 2 3/8 |

| 2 1/2 | 1200 | 167 | 1 1/16 | 2 5/8 |

| 3 | 1200 | 188 | 1 | 2 15/16 |

| 3 1/2 | 1200 | 228 | 1 1/4 | 3 7/16 |

| 4 | 1200 | 228 | 1 1/16 | 3 7/16 |

| 5 | 1200 | 228 | 1 | 3 15/16 |

| 6 | 1800 | 378 | 1 | 4 1/2 |

Fig. 185: Pipe Covering Saddle for 1 1/2″ Insulation

FINISH: Black, galvanized, or painted.

SERVICE: Designed to keep insulation from crushing and to reduce heat losses.

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

NOTE: All saddles are 12” long with the side edges turned up.

| FIG. 185 - 1 1/2″ INSULATION | ||||

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT per 100 | COVERING THK. | C |

| 3/4 | 1200 | 210 | 1 7/16 | 2 1/8 |

| 1 | 1200 | 210 | 1 9/16 | 2 3/8 |

| 1 1/4 | 1200 | 210 | 1 5/8 | 2 5/8 |

| 1 1/2 | 1200 | 210 | 1 1/2 | 2 5/8 |

| 2 | 1200 | 234 | 1 9/16 | 2 15/16 |

| 2 1/2 | 1200 | 276 | 1 7/8 | 3 7/16 |

| 3 | 1200 | 276 | 1 9/16 | 3 7/16 |

| 3 1/2 | 1200 | 321 | 1 13/16 | 3 15/16 |

| 4 | 1200 | 321 | 1 9/16 | 3 15/16 |

| 5 | 1200 | 321 | 1 1/2 | 4 7/16 |

| 6 | 1800 | 442 | 1 1/2 | 5 |

| 8 | 5000 | 581 | 1 1/2 | 6 1/8 |

| 10 | 5000 | 581 | 1 9/16 | 7 1/4 |

| 12 | 5000 | 781 | 1 9/16 | 8 1/4 |

| 14 | 5000 | 781 | 1 1/2 | 8 3/4 |

| 16 | 5000 | 844 | 1 1/2 | 9 3/4 |

| 18 | 5000 | 912 | 1 1/2 | 10 3/4 |

| 20 | 7200 | 1044 | 1 1/2 | 11 7/8 |

| 24 | 7200 | 1231 | 1 1/2 | 13 7/8 |

| 30 | 7200 | 1333 | 1 1/2 | 16 7/8 |

| 36 | 7200 | 1803 | 1 1/2 | 19 7/8 |

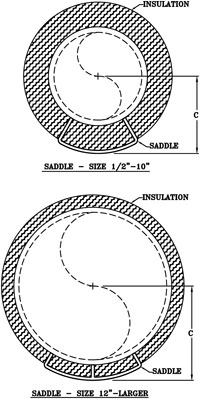

Fig. 186: Pipe Covering Saddle for 2″ Insulation

FINISH: Black, galvanized, or painted.

SERVICE: Designed to keep insulation from crushing and to reduce heat losses.

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

NOTE: All saddles are 12” long with the side edges turned up.

| FIG. 186 - 2″ INSULATION | ||||

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT per 100 | COVERING THK. | C |

| 3/4 | 1200 | 276 | 1 7/8 | 2 5/8 |

| 1 | 1200 | 276 | 2 1/8 | 2 15/16 |

| 1 1/4 | 1200 | 276 | 1 15/16 | 2 15/16 |

| 1 1/2 | 1800 | 318 | 2 5/16 | 3 1/2 |

| 2 | 1800 | 319 | 2 1/8 | 3 1/2 |

| 2 1/2 | 1800 | 319 | 2 5/16 | 4 |

| 3 | 1800 | 358 | 2 1/16 | 4 |

| 3 1/2 | 1800 | 358 | 2 1/4 | 4 1/2 |

| 4 | 1800 | 358 | 2 1/16 | 4 1/2 |

| 5 | 1800 | 358 | 2 | 5 |

| 6 | 1800 | 573 | 2 | 5 9/16 |

| 8 | 1800 | 634 | 2 | 6 9/16 |

| 10 | 5000 | 765 | 2 1/16 | 7 3/4 |

| 12 | 5000 | 988 | 2 1/16 | 8 3/4 |

| 14 | 5000 | 988 | 2 | 9 1/4 |

| 16 | 5000 | 1040 | 2 | 10 1/4 |

| 18 | 7200 | 1040 | 2 | 11 3/8 |

| 20 | 7200 | 1161 | 2 | 12 3/8 |

| 24 | 7200 | 1335 | 2 | 14 3/8 |

| 30 | 7200 | 1408 | 2 | 17 3/8 |

| 36 | 7200 | 1893 | 2 | 20 3/8 |

Fig. 187: Pipe Covering Saddle for 2 1/2″ Insulation

FINISH: Black , galvanized, or painted.

SERVICE: Designed to keep insulation from crushing and to reduce heat losses.

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

NOTE: All saddles are 12” long with the side edges turned up.

| FIG. 187 - 2 1/2″ INSULATION | ||||

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT (lb. per 100) | COVERING THK. | C |

| 1 1/4 | 1200 | 361 | 2 7/16 | 3 7/16 |

| 1 1/2 | 1800 | 361 | 2 13/16 | 4 |

| 2 | 1800 | 361 | 2 5/8 | 4 |

| 2 1/2 | 1800 | 406 | 2 7/8 | 4 1/2 |

| 3 | 1800 | 406 | 2 9/16 | 4 1/2 |

| 3 1/2 | 1800 | 446 | 2 3/4 | 5 |

| 4 | 1800 | 446 | 2 9/16 | 5 |

| 5 | 1800 | 446 | 2 9/16 | 5 9/16 |

| 6 | 1800 | 651 | 2 1/2 | 6 1/16 |

| 8 | 1800 | 721 | 2 11/16 | 7 3/16 |

| 10 | 5000 | 820 | 2 9/16 | 8 1/4 |

| 12 | 5000 | 1045 | 2 5/8 | 9 1/4 |

| 14 | 5000 | 1045 | 2 1/2 | 9 3/4 |

| 16 | 7200 | 1107 | 2 1/2 | 10 7/8 |

| 18 | 7200 | 1239 | 2 1/2 | 11 7/8 |

| 20 | 7200 | 1239 | 2 1/2 | 12 7/8 |

| 24 | 7200 | 1434 | 2 1/2 | 14 7/8 |

| 30 | 7200 | 1999 | 2 1/2 | 17 7/8 |

| 36 | 7200 | 2020 | 2 1/2 | 20 7/8 |

Fig. 188: Pipe Covering Saddle for 3″ Insulation

FINISH: Black , galvanized, or painted.

SERVICE: Designed to keep insulation from crushing and to reduce heat losses.

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

NOTE: All saddles are 12” long with the side edges turned up.

| FIG. 188 - 3″ INSULATION | ||||

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT (lb. per 100) | COVERING THK. | C |

| 2 | 1800 | 449 | 3 1/8 | 4 1/2 |

| 2 1/2 | 1800 | 449 | 3 3/8 | 5 |

| 3 | 1800 | 491 | 3 1/16 | 5 |

| 3 1/2 | 1800 | 491 | 3 5/16 | 5 9/16 |

| 4 | 1800 | 491 | 3 1/16 | 5 9/16 |

| 5 | 1800 | 491 | 3 1/16 | 6 1/16 |

| 6 | 1800 | 773 | 3 | 6 9/16 |

| 8 | 1800 | 773 | 3 1/8 | 7 11/16 |

| 10 | 5000 | 884 | 3 1/16 | 8 3/4 |

| 12 | 5000 | 1135 | 3 1/16 | 9 3/4 |

| 14 | 5000 | 1135 | 3 | 10 1/4 |

| 16 | 7200 | 1330 | 3 | 11 3/8 |

| 18 | 7200 | 1330 | 3 | 12 3/8 |

| 20 | 7200 | 1342 | 3 | 13 3/8 |

| 24 | 7200 | 2034 | 3 | 15 3/8 |

| 30 | 7200 | 2137 | 3 | 18 3/8 |

| 36 | 7200 | 2158 | 3 | 21 3/8 |

Fig. 189: Pipe Covering Saddle for 4″ Insulation

FINISH: Black , galvanized, or painted.

SERVICE: Designed to keep insulation from crushing and to reduce heat losses.

ORDERING: Specify figure number, pipe size, description, insulation thickness and finish.

NOTE: All saddles are 12” long with the side edges turned up.

| FIG. 189 - 4″ INSULATION | ||||

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT (lb. per 100) | COVERING THK. | C |

| 4 | 1800 | 611 | 4 1/16 | 6 9/16 |

| 5 | 1800 | 611 | 4 3/16 | 7 3/16 |

| 6 | 1800 | 1020 | 4 1/8 | 7 11/16 |

| 8 | 1800 | 1020 | 4 3/16 | 8 11/16 |

| 10 | 5000 | 1083 | 4 1/16 | 9 3/4 |

| 12 | 5000 | 1398 | 4 1/8 | 10 3/4 |

| 14 | 5000 | 1398 | 4 | 11 1/4 |

| 16 | 7200 | 1530 | 4 | 12 3/8 |

| 18 | 7200 | 1530 | 4 | 13 3/8 |

| 20 | 7200 | 2279 | 4 | 14 3/8 |

| 24 | 7200 | 2305 | 4 | 16 3/8 |

| 30 | 7200 | 2396 | 4 | 19 3/8 |

| 36 | 7200 | 2413 | 4 | 22 3/8 |

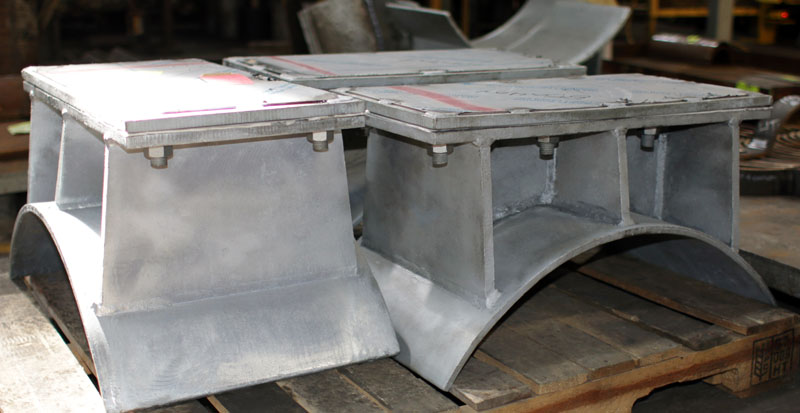

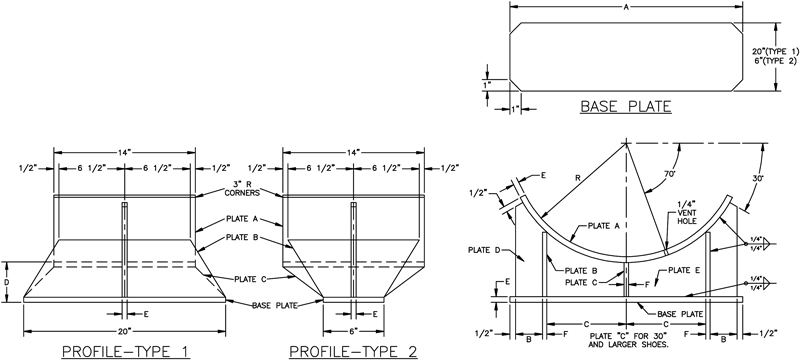

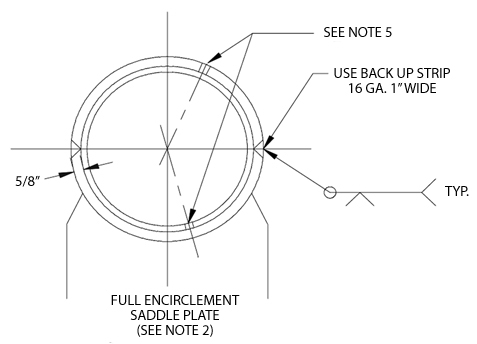

Fig. 2000: Heavy Duty Pipe Saddles

NOTE:

1. Tolerances: R=1%-0

Other Dimension – 1/16, Except Plate Thickness – 1/32 Angle – 1 1/4 Deg.

2. Full Encirclement Saddle Plates shall be used on all cross-country pipelines, on Grade X-46 or higher strength pipe, and on all station pipework designed to operate at or in excess of 90% of Min. Specified yield strength. Segmental Saddle Plates shall be used on station pipework designed to operate at less than 50% of min. yield strength.

3. For maximum spans of pipelines using saddles use Standard Engineering Practice.

4. Pipe Support of Sleeper Under the Saddle shall be designed to accommodate full axial movement of the pipeline and saddle.

5. Vent hole 1/4 to be drilled in each segment of saddle.

HOW TO ORDER: Specify figure number, pipe size, and description.

| PIPE SIZE | RADIUS | DIMENSIONS | APPROX. WEIGHT lbs. |

||||||

| R | A | B | C | D | E | F | Type 1 | Type 2 | |

| 20 | 10 | 20 1/2 | 2 3/8 | 7 | 4 | 1/2 | 3/8 | 165 | 90 |

| 22 | 11 | 22 | 2 5/8 | 7 1/2 | 4 | 1/2 | 3/8 | 185 | 100 |

| 24 | 12 | 23 1/2 | 2 7/8 | 8 | 4 | 1/2 | 3/8 | 195 | 105 |

| 26 | 13 | 25 1/2 | 3 3/8 | 8 1/2 | 4 | 1/2 | 3/8 | 210 | 110 |

| 28 | 14 | 27 | 3 5/8 | 9 | 4 | 1/2 | 3/8 | 230 | 120 |

| 30 | 15 | 29 | 4 | 9 1/2 | 4 | 5/8 | 1/2 | 315 | 175 |

| 32 | 16 | 31 | 4 1/2 | 10 | 4 | 5/8 | 1/2 | 330 | 190 |

| 34 | 17 | 32 | 5 | 10 | 4 | 5/8 | 1/2 | 355 | 200 |

| 36 | 18 | 34 | 5 | 11 | 4 | 5/8 | 1/2 | 375 | 210 |

| 38 | 19 | 36 | 6 | 11 | 4 | 5/8 | 1/2 | 395 | 220 |

| 40 | 20 | 38 | 6 | 12 | 4 | 5/8 | 1/2 | 420 | 235 |

| 42 | 21 | 40 | 6 | 13 | 4 | 5/8 | 1/2 | 440 | 250 |

| 48 | 24 | 46 | 6 | 16 | 4 | 5/8 | 1/2 | 510 | 285 |

| 54 | 27 | 52 | 7 | 19 | 4 | 5/8 | 1/2 | 575 | 320 |

| 60 | 30 | 58 | 8 | 20 | 4 | 5/8 | 1/2 | 625 | 360 |

Heavy Duty Pipe Saddles

FINISH: Black, galvanized, or painted.

SERVICE: General piping

ORDERING: Specify figure number, pipe size, description, finish and height.

*Max load varies based on height.

| PIPE SIZE | PLATE SIZE A | PIPE SIZE B | PIPE SIZE C | PLATE SIZE D | MAX LOAD* |

| 3 | 5 x 1/4 | 1 1/2 | 2 1/2 | 8 x 8 x 3/8 | 2,000 |

| 4 | 6 x 1/4 | 2 | 3 | 8 x 8 x 3/8 | 3,800 |

| 6 | 6 x 1/4 | 2 | 3 | 8 x 8 x 3/8 | 3,800 |

| 8 | 7 x 3/8 | 3 | 4 | 8 x 8 x 1/2 | 3,800 |

| 10 | 7 x 3/8 | 3 | 4 | 8 x 8 x 1/2 | 3,800 |

| 12 | 9 x 3/8 | 4 | 6 | 10 x 10 x 3/4 | 3,800 |

| 14 | 9 x 3/8 | 4 | 6 | 10 x 10 x 3/4 | 5,300 |

| 16 | 11 x 3/8 | 6 | 8 | 12 x 12 x 3/4 | 5,300 |

| 18 | 11 x 3/8 | 6 | 8 | 12 x 12 x 3/4 | 6,700 |

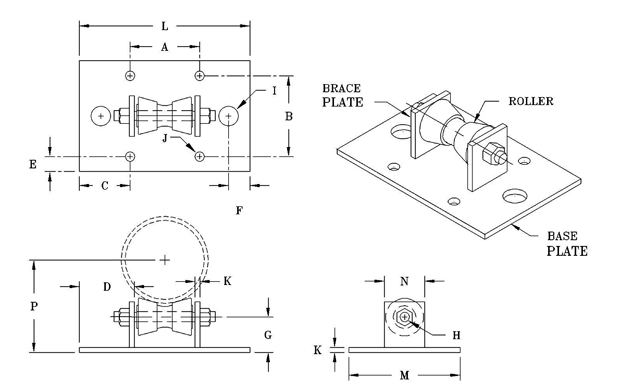

Fig. 210: Pipe Roller Chair

MATERIAL: Cast iron roll, steel roll rod, steel continuous thread rods and hex nuts.

SERVICE: For support of pipe where horizontal movement due to expansion and contraction will occur and where vertical adjustment up to 6” may be necessary.

HOW TO SIZE:

1. If roll is to support bare pipe, select the size directly from nominal pipe size.

2. If used with pipe covering protection saddle, see pipe insulation chart for size of pipe roll.

3. If roll is to support covered pipe, the O.D. of the covering should not be greater than the O.D. of the pipe for which the roll was designed.

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD (lb.) | WEIGHT (lb. per 100) | A | B | C | D | E | F | STEEL SIZE G | BOLT SIZE H |

| 2 | 600 | 110 | 3 1/16 | 1 9/16 | 1 1/2 | 3/8 | 1 1/4 | 3 7/8 | 1/4 x 1 1/4 | 3/8 x 1 1/4 |

| 2 1/2 | 660 | 136 | 3 1/2 | 1 7/16 | 1 5/8 | 1/2 | 1 1/4 | 4 3/4 | 1/4 x 1 1/4 | 3/8 x 1 1/4 |

| 3 | 700 | 164 | 3 15/16 | 2 3/16 | 1 3/4 | 1/2 | 2 | 5 1/2 | 1/4 x 1 1/4 | 3/8 x 1 1/4 |

| 3 1/2 | 750 | 250 | 4 1/2 | 2 1/2 | 2 | 1/2 | 2 | 6 | 3/8 x 1 1/2 | 1/2 x 1 1/2 |

| 4 | 750 | 305 | 5 1/16 | 2 3/4 | 2 5/16 | 1/2 | 2 | 6 1/2 | 3/8 x 1 1/2 | 1/2 x 1 1/2 |

| 5 | 750 | 428 | 5 15/16 | 3 7/16 | 2 1/2 | 5/8 | 2 1/2 | 7 7/8 | 3/8 x 1 1/2 | 1/2 x 1 1/2 |

| 6 | 1070 | 535 | 6 3/4 | 4 | 2 3/4 | 3/4 | 3 1/4 | 9 1/2 | 3/8 x 1 3/4 | 1/2 x 1 1/2 |

| 8 | 1350 | 690 | 8 1/4 | 5 1/4 | 3 | 7/8 | 4 | 11 3/4 | 3/8 x 2 | 1/2 x 1 1/2 |

| 10 | 1730 | 1263 | 9 7/8 | 6 1/4 | 3 5/8 | 7/8 | 5 | 14 1/4 | 1/2 x 2 | 1/2 x 1 1/2 |

| 12 | 2400 | 2060 | 11 9/16 | 7 7/16 | 4 1/8 | 1 | 6 | 16 1/2 | 1/2 x 2 | 1/2 x 1 1/2 |

| 14 | 3130 | 2680 | 13 1/16 | 8 5/16 | 4 3/4 | 1 1/8 | 7 | 18 5/8 | 1/2 x 2 1/2 | 5/8 x 2 |

| 16 | 3970 | 4575 | 14 3/8 | 9 3/8 | 5 | 1 1/4 | 8 | 21 | 5/8 x 2 1/2 | 5/8 x 2 1/2 |

| 18 | 4200 | 4700 | 15 5/8 | 10 3/8 | 5 1/4 | 1 1/4 | 9 | 22 7/8 | 5/8 x 2 1/2 | 5/8 x 2 1/2 |

| 20 | 4550 | 6200 | 17 1/4 | 11 1/2 | 5 3/4 | 1 3/8 | 10 | 25 1/2 | 5/8 x 3 | 3/4 x 3 |

| 24 | 6160 | 9990 | 20 13/16 | 13 13/16 | 7 | 1 1/2 | 12 | 30 | 3/4 x 3 | 3/4 x 3 |

Fig. 215: Adjustable Pipe Roll Support

MATERIAL: Cast iron roll and sockets, steel roll rod, steel continuous thread rods and hex nuts.

SERVICE: For support of pipe where horizontal movement due to expansion and contraction will occur and where vertical adjustment up to 6” may be necessary.

SIZE: If roll is to support bare pipe, select the size directly from nominal pipe size.

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | APPROX. WEIGHT lbs. per 100 | A | B | C | D | H |

| 1 | 113 | 3/8 | 3 | 1 1/2 | 9 1/2 | 1 1/16 |

| 1 1/4 | 117 | 3/8 | 3 3/8 | 1 7/8 | 9 1/2 | 1 1/4 |

| 1 1/2 | 120 | 3/8 | 3 5/8 | 2 1/8 | 9 1/2 | 1 3/8 |

| 2 | 125 | 3/8 | 4 1/8 | 2 5/8 | 9 1/2 | 1 5/8 |

| 2 1/2 | 229 | 1/2 | 4 7/8 | 3 1/8 | 9 1/2 | 1 15/16 |

| 3 | 242 | 1/2 | 5 1/2 | 3 3/4 | 9 1/2 | 2 1/4 |

| 3 1/2 | 269 | 1/2 | 6 1/8 | 4 1/2 | 10 | 2 9/16 |

| 4 | 375 | 5/8 | 6 3/4 | 4 3/4 | 10 | 2 13/16 |

| 5 | 469 | 5/8 | 8 1/16 | 5 13/16 | 10 | 3 7/16 |

| 6 | 757 | 3/4 | 9 9/16 | 6 7/8 | 11 | 4 |

| 8 | 1101 | 7/8 | 11 15/16 | 8 7/8 | 11 3/4 | 5 1/8 |

| 10 | 1374 | 7/8 | 14 1/16 | 11 | 11 3/4 | 6 3/8 |

| 12 | 1936 | 7/8 | 15 13/16 | 12 1/2 | 11 3/4 | 7 7/16 |

| 14 | 3116 | 1 | 17 3/4 | 14 1/4 | 11 3/4 | 8 3/8 |

| 16 | 4245 | 1 1/8 | 19 3/4 | 16 1/4 | 18 | 9 7/16 |

| 18 | 4655 | 1 1/8 | 21 7/8 | 18 1/4 | 18 | 10 1/2 |

| 20 | 6623 | 1 1/4 | 24 1/4 | 20 1/4 | 18 | 11 5/8 |

| 24 | 10252 | 1 1/2 | 28 5/8 | 24 1/4 | 24 | 14 |

| 30 | 18681 | 1 7/8 | 35 1/2 | 30 1/4 | 24 | 17 7/16 |

Fig. 230: Pipe Roller Chair

MATERIAL: Cast iron roll and stand.

SERVICE: For support of piping that expands and contracts longitudinally and where vertical adjustment is not necessary.

HOW TO SIZE:

1. If roll is to support bare pipe, select size from nominal pipe size.

2. If used with pipe covering protection saddle, see FIG. 183 for size of pipe roll.

INSTALLATION: Two cored holes “I” for anchorage bolting purpose.

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | 2 – 3 1/2 | 4 – 6 | 8 – 10 | 12 – 14 | 16 – 20 | 24 | 30 | 36 – 42 |

| MAX. RECOM. SIZE LOAD, lbs. | 390 | 950 | 2100 | 3075 | 4980 | 6100 | 7500 | 12000 |

| COMPLETE (APPROX. WEIGHT, lbs per 100) | 640 | 885 | 1530 | 2810 | 3965 | 4950 | 9925 | 15200 |

| ROLL AND ROD (APPROX. WEIGHT, lbs per 100) | 90 | 135 | 530 | 1010 | 1565 | 1950 | 3390 | 5700 |

| ROLL ONLY (APPROX. WEIGHT, lbs per 100) | 70 | 110 | 440 | 850 | 1270 | 1450 | 2400 | 4100 |

| PIPE SIZE | A | B | C | D | E | F | G | H | I | J | K | L | M | N | P |

| 2 | 3 7/16 | 4 | 2 1/2 | 2 11/16 | 3/4 | 1 1/16 | 1 3/4 | 9/16 | 1 | 1/2 | 1/4 | 8 7/16 | 5 1/2 | 2 | 3 1/2 |

| 2 1/2 | 3 7/8 | ||||||||||||||

| 3 | 4 1/8 | ||||||||||||||

| 3 1/2 | 4 3/8 | ||||||||||||||

| 4 | 4 11/16 | 4 1/4 | 2 5/8 | 3 | 7/8 | 1 1/16 | 2 | 9/16 | 1 | 1/2 | 1/4 | 9 15/16 | 6 | 3 | 4 3/4 |

| 5 | 5 3/8 | ||||||||||||||

| 6 | 6 | ||||||||||||||

| 8 | 7 | 5 | 3/4 | 1 1/8 | 1 1/2 | 2 1/4 | 3 3/8 | 3/4 | 1 | 5/8 | 3/8 | 8 1/2 | 8 | 3 | 8 5/8 |

| 10 | 9 3/4 | ||||||||||||||

| 12 | 9 1/16 | 6 | 1 | 1 7/16 | 1 | 2 1/2 | 3 3/4 | 7/8 | 1 | 3/4 | 3/8 | 11 1/16 | 8 | 3 | 11 1/4 |

| 14 | 11 7/8 | ||||||||||||||

| 16 | 10 1/4 | 6 1/2 | 1 3/8 | 1 7/8 | 1 1/4 | 2 3/16 | 4 1/4 | 1 1/4 | 1 | 13/16 | 1/2 | 13 | 9 | 4 | 13 5/8 |

| 18 | 14 5/8 | ||||||||||||||

| 20 | 15 5/8 | ||||||||||||||

| 24 | 11 3/8 | 6 1/2 | 1 | 1 9/16 | 1 1/4 | 3 | 4 3/8 | 1 1/2 | 1 | 13/16 | 1/2 | 13 3/8 | 9 | 4 | 17 3/4 |

| 30 | 14 1/4 | 8 | 1 3/8 | 2 3/8 | 1 1/2 | 3 1/2 | 5 1/8 | 1 7/8 | 1 | 1 1/16 | 1/2 | 17 | 11 | 5 | 21 7/8 |

| 36 | 17 | 9 | 1 1/2 | 2 7/16 | 1 1/2 | 4 | 5 3/4 | 2 1/8 | 1 | 1 5/16 | 3/4 | 20 | 12 | 6 | 25 3/4 |

| 42 | 28 7/8 |

Fig. 240: Adjustable Pipe Roller Stand

MATERIAL: Cast iron base plate, stand and roll, steel adjusting screws.

SERVICE: To support pipe lines where vertical and lateral adjustment during installation may be required in addition to provision for expansion and contraction.

HOW TO SIZE: If roll is to support bare pipe, select the size from nominal pipe size (see below).

ORDERING: Specify figure number, pipe size, description and finish.

| SIZE (inches) | MAX. RECOM. LOAD, lbs. | WEIGHT per 100 |

| 2 — 3 1/2 | 390 | 1525 |

| 4 — 6 | 950 | 1930 |

| 8 — 10 | 2100 | 3205 |

| 12 — 14 | 3075 | 5115 |

| 16 — 20 | 4980 | 7130 |

| 24 | 6100 | 8700 |

| 30 | 7500 | 16615 |

| PIPE SIZE | A | B | C | D | D1 | E | F | G | H | J | J1 | K | L | M MAX. | N | P | R | S | T | U | |

| MIN. | MAX. | ||||||||||||||||||||

| 2 | 5 1/8 | 5 3/8 | 1 3/4 | 1 3/4 | 6 7/8 | 8 3/8 | 5 1/2 | 2 3/4 | 1 7/8 | 1/2 | 3 7/8 | 6 3/8 | 1 | 11/16 | 7/8 | 1 | 1/4 | 1 | 5/8 | 3 7/16 | 4 |

| 2 1/2 | 5 3/8 | 5 5/8 | 2 1/8 | ||||||||||||||||||

| 3 | 5 3/4 | 6 | 2 3/8 | ||||||||||||||||||

| 3 1/2 | 6 | 6 1/4 | 2 5/8 | ||||||||||||||||||

| 4 | 6 1/2 | 7 | 2 3/4 | 2 1/16 | 8 1/8 | 9 7/8 | 5 3/4 | 3 3/4 | 2 1/16 | 1/2 | 5 1/8 | 7 3/8 | 1 | 7/8 | 1 1/8 | 1 | 1/4 | 1 | 5/8 | 4 11/16 | 4 1/4 |

| 5 | 7 | 7 1/2 | 3 3/8 | ||||||||||||||||||

| 6 | 7 5/8 | 8 1/8 | 4 | ||||||||||||||||||

| 8 | 10 3/8 | 11 5/8 | 5 1/4 | 3 7/16 | 10 5/8 | … | 6 3/4 | 6 | 3 1/4 | 3/4 | 7 3/8 | … | 1 | 7/8 | 1 3/4 | 1 1/8 | 3/8 | 1 | 3/4 | 7 | 5 |

| 10 | 11 1/2 | 12 3/4 | 6 3/8 | ||||||||||||||||||

| 12 | 13 | 14 1/4 | 7 1/2 | 3 7/8 | 13 | … | 8 | 8 | 4 | 7/8 | 9 1/2 | … | 1 | 7/8 | 1 3/4 | 1 1/8 | 3/8 | 1 | 7/8 | 9 1/16 | 6 |

| 14 | 13 5/8 | 14 7/8 | 8 1/8 | ||||||||||||||||||

| 16 | 15 1/4 | 16 5/8 | 9 3/8 | 4 1/4 | 14 5/8 | … | 8 5/8 | 9 | 4 1/2 | 1 1/4 | 11 1/8 | … | 1 | 1 | 1 7/8 | 1 1/4 | 5/8 | 1 3/16 | 1 | 10 1/4 | 6 1/2 |

| 18 | 16 3/8 | 17 3/4 | 10 3/8 | 1 3/8 | |||||||||||||||||

| 20 | 17 3/8 | 18 3/4 | 11 3/8 | ||||||||||||||||||

| 24 | 19 5/8 | 21 | 13 3/8 | 4 3/8 | 15 3/4 | … | 8 5/8 | 10 | 4 7/16 | 1 3/8 | 12 1/4 | … | 1 | 1 1/8 | 1 7/8 | 1 3/8 | 5/8 | 1 13/16 | 1 | 11 3/8 | 6 1/2 |

| 30 | 24 | 26 3/4 | 16 3/4 | 5 1/8 | 19 1/4 | … | 10 1/2 | 12 1/2 | 5 1/2 | 1 3/4 | 15 3/4 | … | 1 | 1 1/2 | 3 1/4 | 1 5/8 | 3/4 | 1 3/8 | 1 1/4 | 14 1/4 | 8 |

Fig. 182: Non-Metallic Wear Pad

MATERIAL: Vinyl resins

FINISH: As-Is

SIZE RANGE: 1/2″ thru 48″

SERVICE: Recommended to protect un-insulated pipe from the metal supporting structure. Pad to be secured to pipe using epoxy adhesive.

MAX TEMP.: 400°F

ORDERING: Specify figure number, pipe size, description, length and angle.

| PIPE SIZE | THICKNESS | LENGTH L | ANGLE A | RADIUS R |

| 1/2 | 1/4 | 12 | 90 | 7/16 |

| 3/4 | 1/4 | 12 | 90 | 9/16 |

| 1 | 1/4 | 12 | 90 | 5/8 |

| 1 1/4 | 1/4 | 12 | 90 | 7/8 |

| 1 1/2 | 1/4 | 12 | 90 | 1 |

| 2 | 1/4 | 12 | 90 | 1 3/16 |

| 2 1/2 | 1/4 | 12 | 90 | 1 7/16 |

| 3 | 1/4 | 12 | 90 | 1 13/16 |

| 3 1/2 | 1/4 | 12 | 90 | 1 3/4 |

| 4 | 1/4 | 12 | 90 | 2 1/4 |

| 5 | 1/4 | 12 | 90 | 2 13/16 |

| 6 | 1/4 | 12 | 60 | 3 5/16 |

| 8 | 1/4 | 12 | 60 | 4 5/16 |

| 10 | 1/4 | 12 | 60 | 5 3/8 |

| 12 | 1/4 | 12 | 30 | 6 3/8 |

| 14 | 1/4 | 12 | 30 | 7 |

| 16 | 1/4 | 12 | 30 | 8 |

| 18 | 1/4 | 12 | 30 | 9 |

| 20 | 1/4 | 12 | 30 | 10 |

| 24 | 3/8 | 12 | 30 | 12 |

| 26-48 | 3/8 | 12 | 30 | 1/2 of Pipe O.D. |

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});