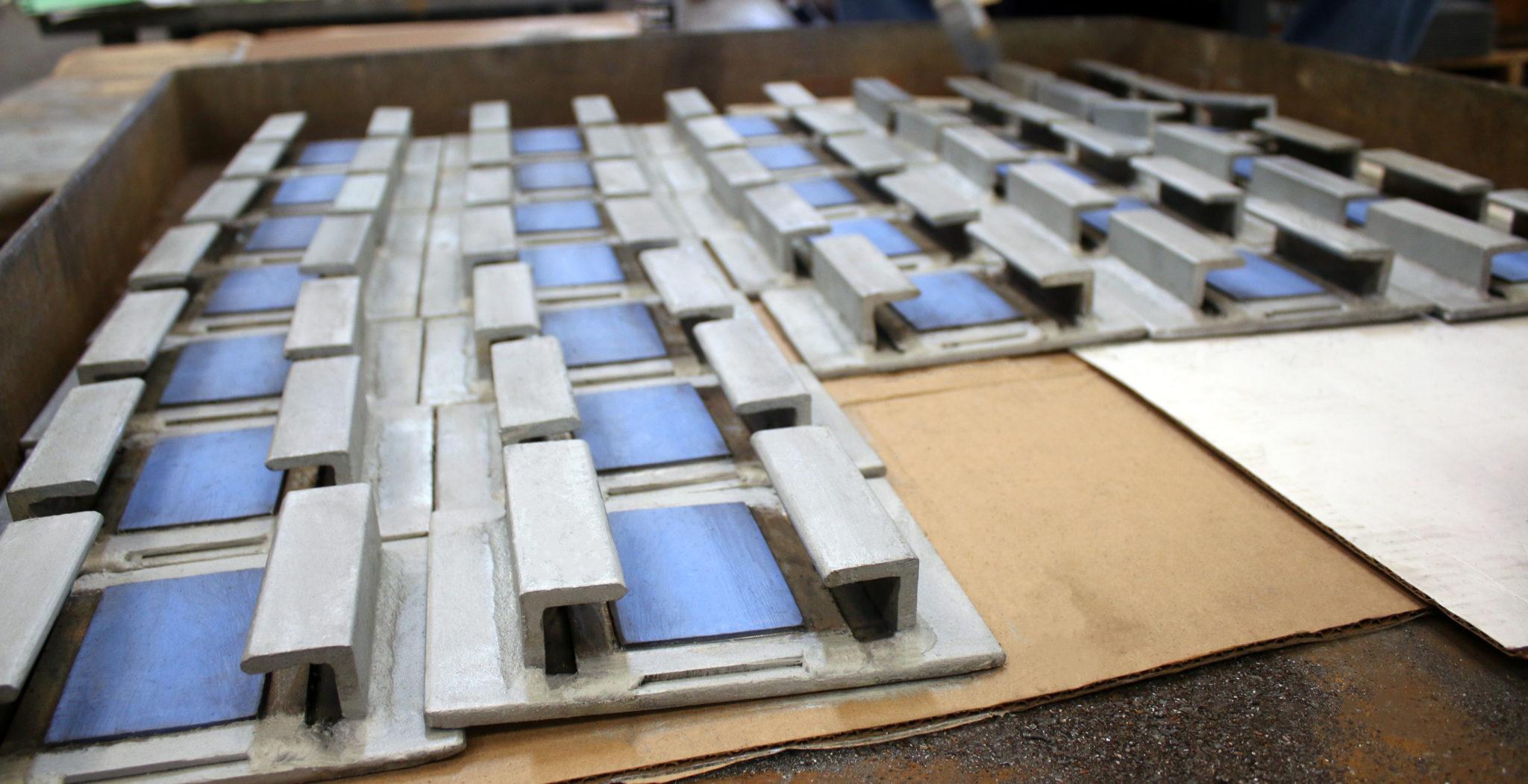

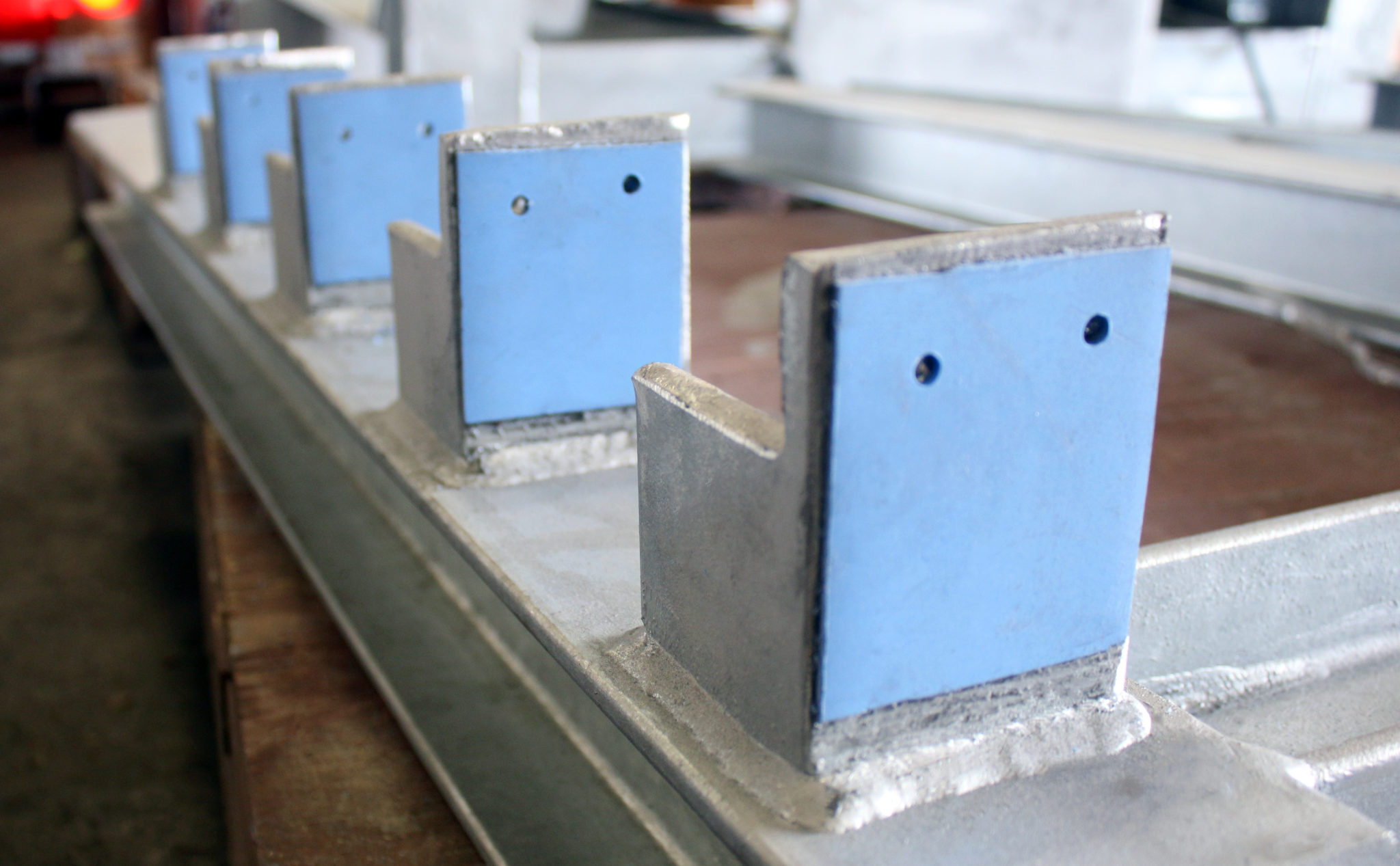

PTFE, 25% Glass Filled Slide Plates

PTFE, 25% glass filled slide plates are primarily used in low heat and high velocity conditions; however, this material can be used in high heat applications in conjunction with other materials. We also use this type of slide plate where there is high wear resistance, no surface treatments necessary or is unaffected by weather conditions.

Acid Plants

Bioenergy Plant

Chemical Plant

Clean Fuels

Cogeneration Plant

Cold / Cryogenc Service

Commercial

Electric Plant

Energy Facility

Ethylene Plant

LLDPE Chemical Plant

LNG Plant

MTBE Plant

Natural Gas Combined Cycle Facility

Natural Gas Processing & Separation

See All

Slide bearings are provided to decrease excessive friction forces that would be generated with direct steel to steel contact. Structural ...Continue Reading

A slide plate is a component that can be fabricated from a variety of materials including PTFE, 25% glass filled, ...Continue Reading

In the majority of cases, bond between the material and its backing plate would become degraded in the presence of ...Continue Reading

The PTFE is generally used as a slide plate either affixed to the supporting steel or the bottom of the ...Continue Reading

More FAQs…

General Dimensions & Specifications

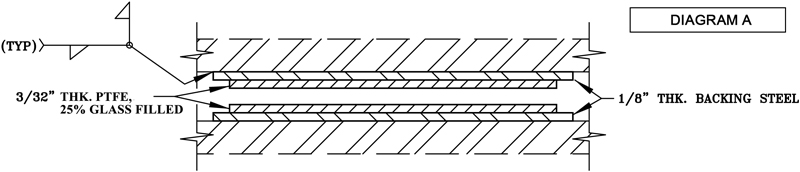

PTFE Standard Assembly

ASSEMBLY:

Standard Assembly: 2 units of 3/32″ PTFE, 25% glass filled, bonded to 1/8″ carbon steel. For field tack welding. 1/2″ lip. Loads to 2000 PSI, Temperature: -320°F to +500°F

Full Weld Assembly:

2 units of 3/32″ PTFE, 25% glass filled, bonded to indicated backing material with 1/2″ lip all around for full welding. Loads to 2000 PSI, Temperature: -320°F to +500°F

PART # — PTP — 3/32″ TFE — 10 Ga. SS — 1/2″ LIP AND SIZE

ORDERING:

1. Please specify the dimensions of the upper plate and dimensions of the lower plate. It is common practice that the upper plate is generally larger than the lower plate.

2. Specify lip dimension (if different than the standard 1/2″).

3. Specify base plate thickness (if different than standard 1/8″).

ADVANTAGES:

• Ease of installation.

• No setting problems.

• Low coefficient of friction.

• No surface treatments, grouting, or expensive mechanical attachment necessary.

• Chemically inert.

• Unaffected by weather conditions.

• Ability to absorb dirt and grit within itself.

• Self-aligning when used in conjunction with elastomeric backing pads.

APPLICATIONS:

• Bridges: Highway bridges, overpasses, railroad bridges.

• Architectural in Wood, Concrete or Steel: Cross beam and girder slip joints, roof slabs and corbels, vibration pads, airport hangar doors, domes.

• Industrial: Heat exchangers, dust collectors, heavy machinery, refinery equipment, wind tunnels, penstocks, vessels, pipelines, air preheaters, atomic energy applications, transmission towers, storage tanks, offshore drilling rigs.

Effect Of Temperature

It has been determined from basic testing that the “ideal” thickness of PTFE, 25% Glass Filled, should be 3/32”. If the design engineer follows the given chart (left) for the Effect of Temperature on PTFE, 25% Glass Filled, there will not be a failure.

Coefficient Of Friction

The Coefficient of Friction of PTFE, 25% Glass Filled, slide plates has been reported to be from 0.01 to 0.2. This depends on the surface preparation, loading, velocity, and the duration of the test. Bonding PTFE, 25% Glass Filled, to metal increases the load capabilities in excess of 2,000 PSI (For design purposes, use 500 PSI). This table shows the coefficient of friction due to the load applied. A maximum coefficient of 0.1 can be used in PTFE, 25% Glass Filled, slide bearing designs without considering sliding speed, temperature, or maintenance.

| Property | Value | ASTM Test Method | |

| Mechanical | Specific Gravity Measured | 2.1-2.3 | D638 |

| Water Absorption (%) | 0.013 | D570-59T | |

| Hardness, Shore D @ 78°F @ 300°F | 57 56 | D2240 | |

| Wear Factor K | Less than 10 x 10-10 | ||

| Tensile Strength (PSI) | 2,000 min. | D1457-56T | |

| Tensile Elongation | 200 - 250 | D1457-56T | |

| Flexural Strength (PSI) | 606 | D790-59T | |

| Modules (PSI) | 2.93 x 105 | D638 | |

| Compressive Strength (PSI) 0.2% offest | 1870 | D790-59T | |

| Deformation at 78°F, 200 PSI 24 hr. Permanent Deformation (%) | 7.1 3.9 | D621-59 (modified) | |

| Deformation at 78°F, 200 PSI 100 hr. Permanent Deformation (%) | 8.9 4.4 | ||

| Coefficient of Friction | 0.06 for loads > 500 PSI static | Modified | |

| Electrical | Dielectrical Strength in air (v per mil) | 327 | D149A |

| Dielectrical Constant @ 60 cps | 2.63 | D150-54T | |

| Volume Resistivity (ohm-cm) | 1013 | D257-57T | |

| Thermal | Coefficient of Linear Thermal Expansion (per °F) | 6.89 x 10-5 | D694-44 |

| Coefficient of Thermal Expansion Conductivity (Btu-In.) hr-sq. (ft. °F) | 3.12 | Cenco-Fitch | |

| Continuous Service Temperature | 550 | Various | |

| Weatherability | Unaffected | Physical exposure |

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});