Thermoplastic Isolator (TPI)

Thermoplastic isolators (TPI) provide optimum support and eliminate pipe contact with the supporting steel. TPI is used as corrosion prevention between the steel pipe and steel pipe support.

General Dimensions & Specifications

View PDF Version of Thermoplastic Isolator (TPI)

PT&P’s TPI – The Lowest Cost, Most Comprehensive Solution for Corrosion at Pipe Supports

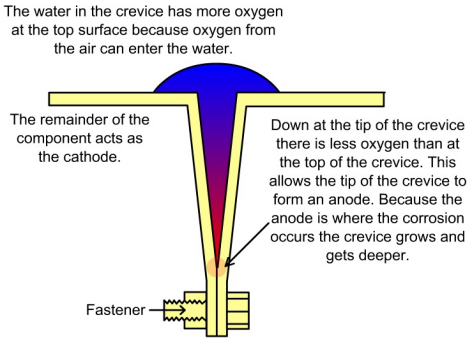

PT&P has consulted with hundreds of customers on one of the most common problems for operating plants – corrosion at the point of contact between the steel pipe and the steel pipe support. As seen in Figure 1, a crevice is formed at the point of contact. When water accumulates in the crevice, the oxygenation level of the water at the surface is higher than the water at the depth of the crevice.

Figure 1 Crevice Corrosion

PT&P has used its 40+ years of experience as a leader in pipe supports in designing our TPI solution to be the most effective and easiest to deploy solution in the market. Key advantages of PT&P’s TPI offering include:

Economical Pricing – PT&P’s TPI offering is priced to be highly cost-effective compared to other providers

Highly Customizable – Our unique manufacturing approach allows us to customize far more easily than any other provider. Customization options include height/width/length of TPI, hole sizes, hole locations, and special shapes. *View more on manufacturing

Complete Assemblies – PT&P reduces complexity in product selection by offering complete assemblies rather than just individual components. We are the only provider of TPI type of solutions that is not a “point solution” provider. Also, we are the ONLY global provider to integrate vibration pads and TPI into our assemblies. If you wanted to purchase a configuration for a clamp with both TPI equivalent and vibration pads, you would have to develop the design, source the materials with requests for customization, and assemble it yourself.

Assemblies that can be purchased include:

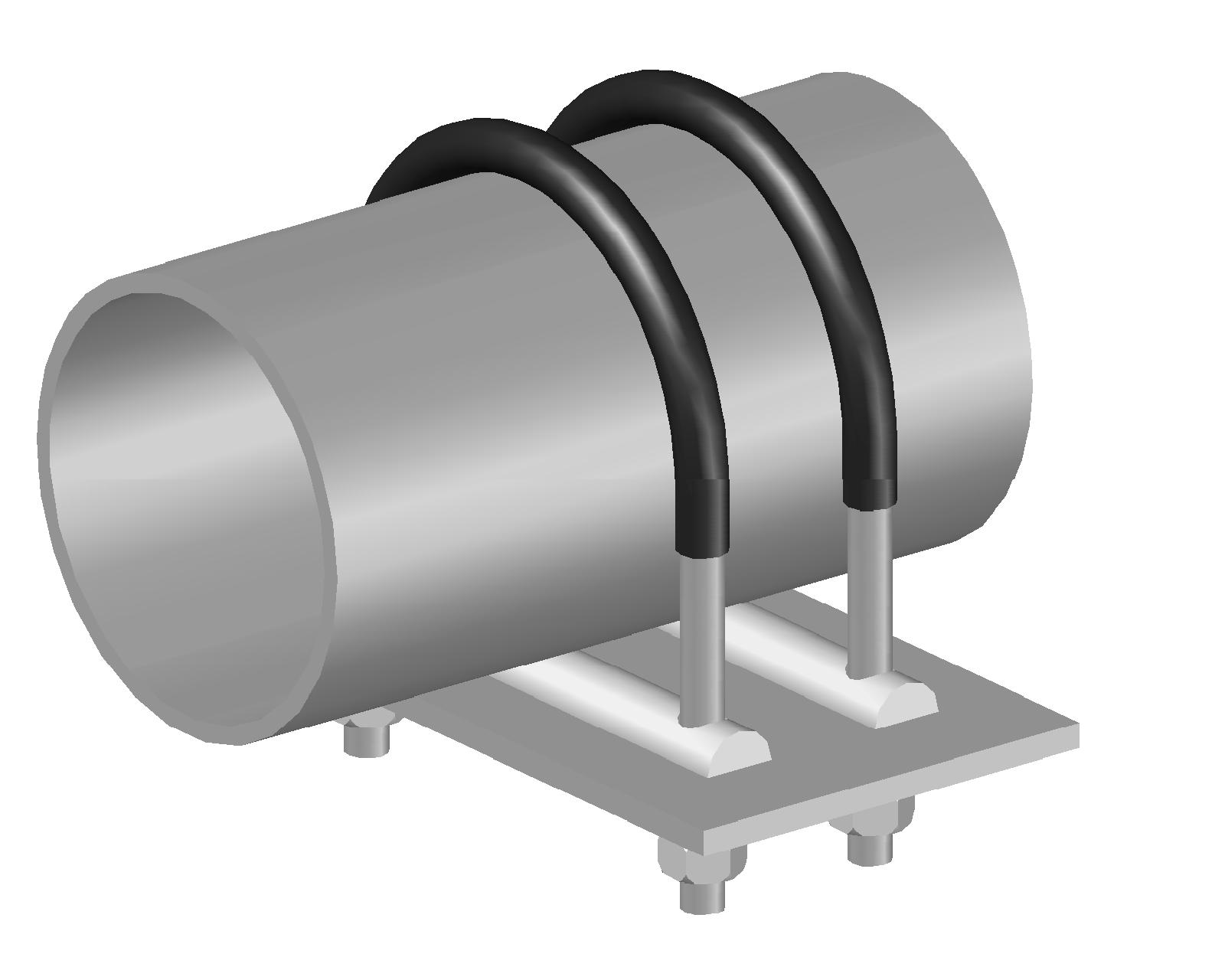

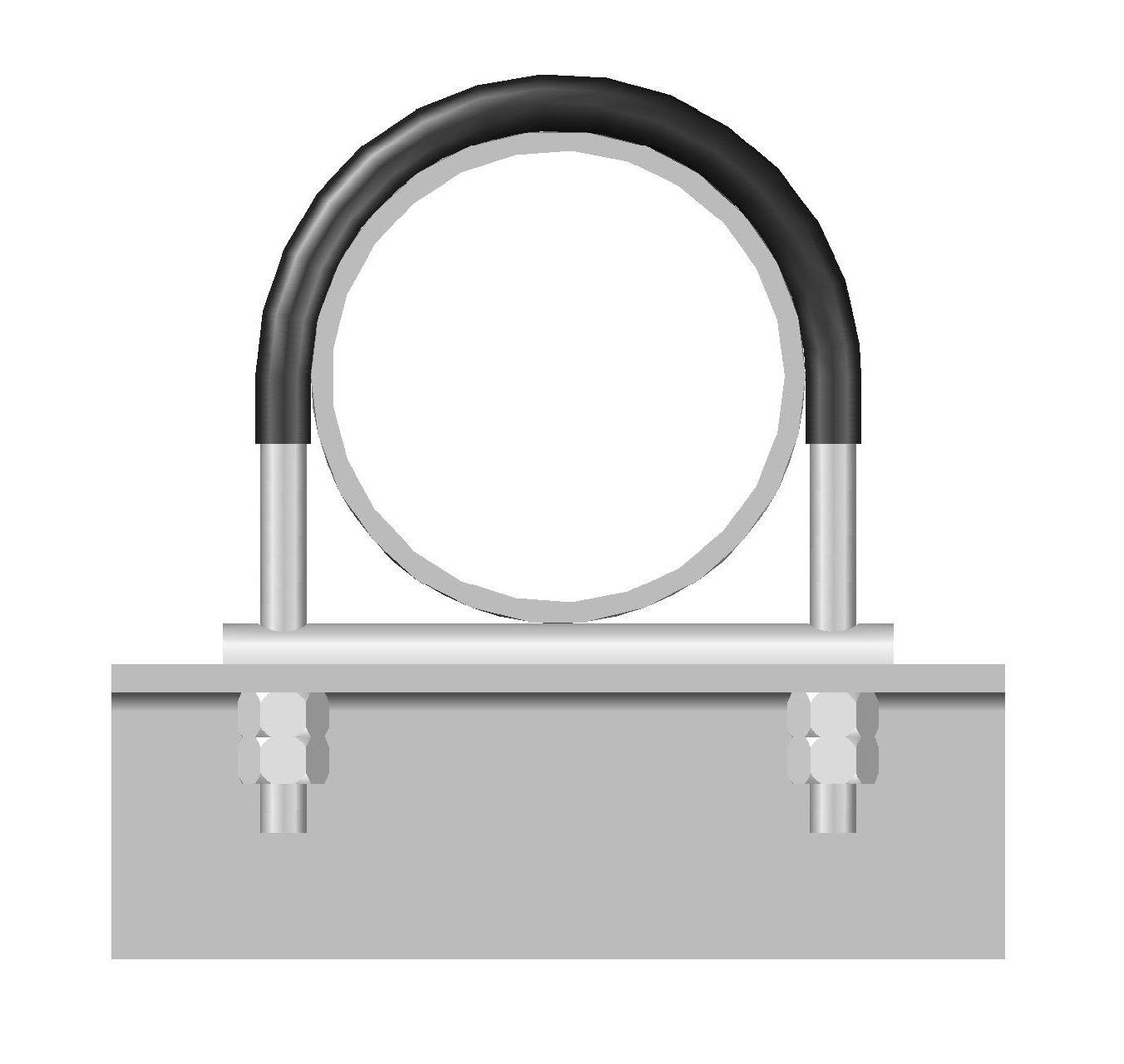

U-Bolts – including the addition of vibration pads (optional) – see Figure 2

Clamps – PT&P’s entire range of clamps can be integrated with TPI Clips as well as vibration pads – see Figure 3

Hold-Downs – PT&P’s entire range of Hold-Downs can be integrated with TPI clips and rods as well as vibration pads – see Figure 4

Figure 2 – PT&P Super U-Bolt with TPI and Vibration Pad |

Figure 3 – PT&P Pre-Assembled Pipe Clamp with TPI Clips and Vibration Pad |

Figure 4 – PT&P Pre-Assembled Hold-Down Pipe Clamp with TPI |

|

|

|

Extreme Loads and Temperature Requirements – PT&P has extensive experience supporting custom requirements. We can develop solutions for unique scenarios by selecting different materials and developing a custom design. *View more on Finite Element Analysis (FEA)

Proven Performance – the performance of PT&P TPI is comparable to or superior to other providers. We have supplied solutions to the largest Engineering, Procurement, and Construction (EPC) in the US as well as many major Oil and Gas and Chemical operating companies.

For PT&P U-Bolts, Clamps, and Hold-Downs, all items in the PT&P catalog can be ordered with TPI. However, the addition of TPI will alter the clamp or hold-down sizing requirement. PT&P simplifies the process by taking care of all the work in terms of designing the appropriate clamp sizing to accommodate the TPI and vibration pad if that is added.

PT&P needs the following information for completed assemblies:

U-Bolts – specify U-Bolt figure and whether a vibration pad should be added *View Super U-Bolts

Clamps – specify clamp type, pipe size and whether a vibration pad should be added

Hold-Downs – specify pipe size and Hold-Down type and whether vibration pad should be added

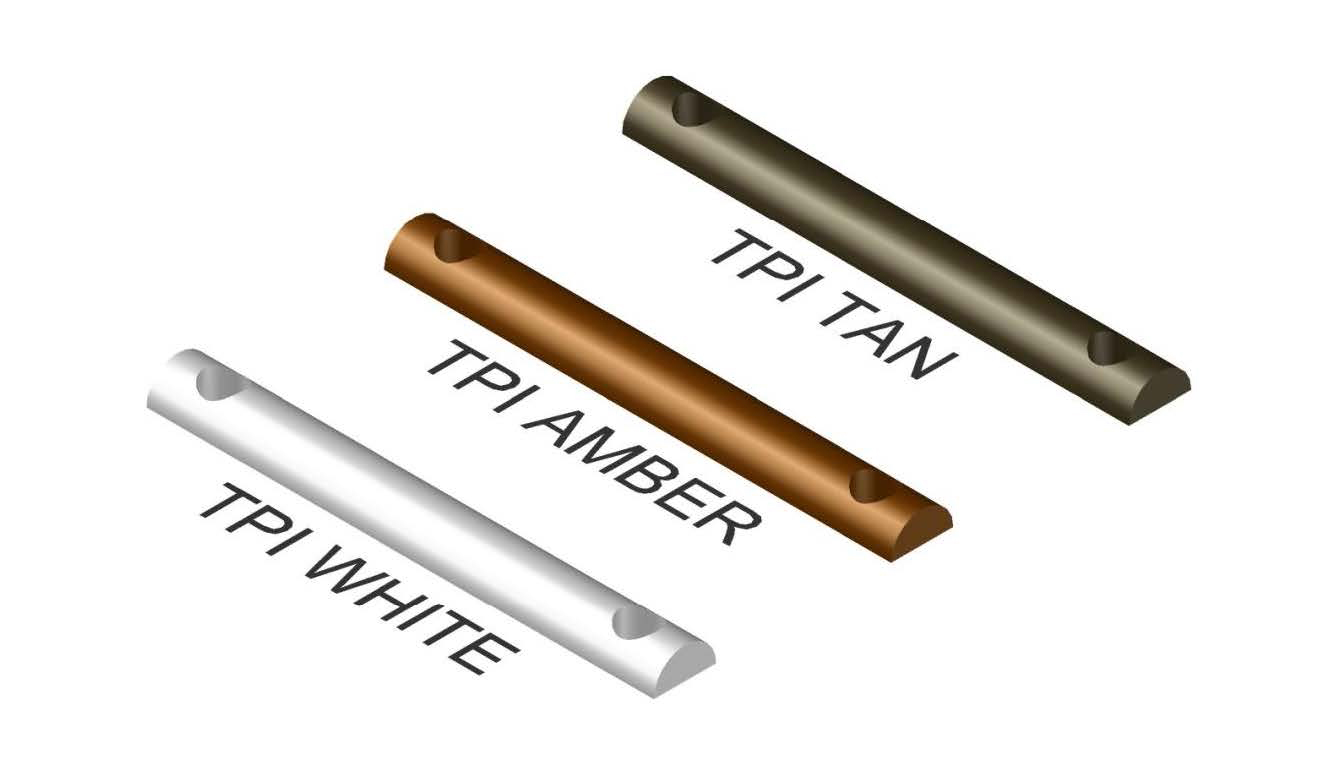

TPI can also be ordered stand-alone. It is also offered in strip format, clips, or pre-configured to be part of a U-Bolt. TPI Strips are offered in the sizes shown below. PT&P will cut to length per the customer request with lengths up to 10 feet.

Figure 5 PT&P TPI Strip Options

| TPI Width | TPI Height | TPI Length |

|---|---|---|

| 3/4” | 5/16" | Customer Specified up to 10 ft |

| 1" | 7/16" | Customer Specified up to 10 ft |

| 1-1/2" | 11/16" | Customer Specified up to 10 ft |

| 2" | 1" | Customer Specified up to 10 ft |

| Custom per Request | Custom per Request |

PT&P options for TPI clips are shown in Figure 5. For clips, customers need to specify the width of clamps.

Figure 6 PT&P Clip Options

| Pipe Size | Clips Per Clamp | Width |

|---|---|---|

| 3" | 4 | Customer Specified |

| 4" | 4 | Customer Specified |

| 6" | 6 | Customer Specified |

| 8" | 8 | Customer Specified |

| 10" | 8 | Customer Specified |

| 12" | 8 | Customer Specified |

| 14" | 8 | Customer Specified |

| 16" | 10 | Customer Specified |

| 20" | 10 | Customer Specified |

| 24" | 12 | Customer Specified |

| 26" | 14 | Customer Specified |

| 28" | 14 | Customer Specified |

| 30" | 16 | Customer Specified |

| 36" | 16 | Customer Specified |

| >36" | Custom Designed | Customer Specified |

For TPI U-Bolts Strips (e.g. PT&P does not supply U-Bolt, just TPI), Figure 6 shows PT&P options.

Figure 7 TPI U-Bolt Strip Options

| Pipe Size | Bolt Diameter | TPI Length | TPI Hold Dia. | TPI Width | TPI Height |

|---|---|---|---|---|---|

| 1/2" | 1/4" | 2-1/2" | 3/8" | 3/4" | 5/16" |

| 1/2" | 3/8" | 2-1/2" | 1/2" | 1" | 7/16" |

| 3/4" | 1/4" | 3" | 3/8" | 3/4" | 5/16" |

| 3/4" | 3/8" | 3" | 1/2" | 1" | 7/16" |

| 1" | 1/4" | 3" | 3/8" | 3/4" | 5/16" |

| 1" | 3/8" | 3" | 1/2" | 1" | 7/16" |

| 1-1/4" | 3/8" | 3-1/2" | 1/2" | 1" | 7/16" |

| 1-1/2" | 3/8" | 4" | 1/2" | 1" | 7/16" |

| 2" | 3/8" | 4-1/2" | 1/2" | 1" | 7/16" |

| 2-1/2" | 1/2" | 5" | 5/8" | 1" | 7/16" |

| 3" | 1/2" | 6" | 5/8" | 1" | 7/16" |

| 4" | 1/2" | 7" | 5/8" | 1" | 7/16" |

| 5" | 1/2" | 8" | 5/8" | 1" | 7/16" |

| 6" | 5/8" | 9" | 11/16" | 1" | 7/16" |

| 8" | 5/8" | 11" | 11/16" | 1" | 7/16" |

| 10" | 3/4" | 13-1/2" | 7/8" | 1-1/2" | 11/16" |

| 12" | 7/8" | 16" | 1" | 1-1/2" | 11/16" |

| 14" | 7/8" | 17" | 1" | 1-1/2" | 11/16" |

| 16" | 7/8" | 19" | 1" | 1-1/2" | 11/16" |

| 18" | 1" | 21-1/2" | 1-1/8" | 1-1/2" | 11/16" |

| 20" | 1" | 23-1/2" | 1-1/8" | 1-1/2" | 11/16" |

| 24" | 1" | 27-1/2" | 1-1/8" | 1-1/2" | 11/16" |

| 28" | 1" | 31-1/2" | 1-1/8" | 1-1/2" | 11/16" |

| 30" | 1" | 33-1/2" | 1-1/8" | 1-1/2" | 11/16" |

| 36" | 1" | 39-1/2" | 1-1/8" | 1-1/2" | 11/16" |

| Custom on Request |

Installation of TPI:

TPI can be placed or attached to structural steel by three different methods.

• Self-tapping screw or bolting

• Double-sided adhesive tape

• With u-bolt

There is a total of 3 different types of TPI available based on thermal properties.

• TPI White – Maximum Service Temperature 181°F

• TPI Amber – Maximum Service Temperature 340°F

• TPI Tan – Maximum Service Temperature 480°F

| TPI White | TPI Amber | TPI Tan | ||

| Property Value | ASTM Test | Imperial | Imperial | Imperial |

| Density | D792 | 0.0516 lb/in3 | 0.0458 lb/in3 | 0.047 lb/in3 |

| Tensile Strength | D638 | 11,000 psi | 17,000 psi | 16,000 psi |

| Tensile Modulus of Elasticity | D638 | 450 ksi | 500 ksi | 630 ksi |

| Elongation (At Break) | D638 | 30% | 60% | 40% |

| Flexural Modulus of Elasticity | D790 | 450 ksi | 500 ksi | 600 ksi |

| Flexural Strength | D790 | 13 ksi | 20 ksi | 25 ksi |

| Compressive Stress | D695 | 16 ksi | 22 ksi | 20 ksi |

| Coefficient of Friction | QTM 55007 | 0.25 | 0.42 | 0.32 |

| IZOD Impact (Notched) | D256 | 1 ft-lb/in | 0.5 ft-lb/in | 0.6 ft-lb/in |

| Rockwell Hardness | D785 | M 88 | M 115 | M 105 |

| Maximum Service Temperature | (Long Term) | 181ºF | 340ºF | 480ºF |

| Melting Point | D3418 | 347ºF | 410ºF | 644ºF |

| Coefficient of Linear Expansion | E831 | 47 µin/in/ºF | 31 µin/in/ºF | - |

| Flammability Rating | UL94 | HB | V-0 | V--0 |

| Electric Strength | D149 | 450 V/mil | 830 V/mil | 480 V/mil |

The tables below show a comparison of TPI versus a leading competitor.

| Property Value | ASTM Test | TPI - White | Competitor |

| Density | D792 | 0.0516 lb/in3 | 0.0509 lb/in3 |

| Tensile Strength | D638 | 11,000 psi | 9,400 psi |

| Tensile Modulus of Elasticity | D638 | 450 ksi | 380 ksi |

| Elongation (At Break) | D638 | 0.3 | 30-60% |

| Flexural Modulus of Elasticity | D790 | 450 ksi | 400 ksi |

| Flexural Strength | D790 | 13 ksi | 13 ksi |

| Compressive Stress | D695 | 16 ksi | 15 ksi |

| Coefficient of Friction | QTM 55007 | 0.25 | 0.25 |

| IZOD Impact (Notched) | D256 | 1 ft-lb/in | 1 ft-lb/in |

| Rockwell Hardness | D785 | M 88 | M 88 |

| Maximum Service Temperature | (Long Term) | 181ºF | 181ºF |

| Melting Point | D3418 | 347ºF | 329ºF |

| Coefficient of Linear Expansion | E831 | 47 µin/in/ºF | 54 µin/in/ºF |

| Heat Deflection Temperature, 264 psi | D648 | 250ºF | 220ºF |

| Flammability Rating | UL94 | HB | HB |

| Electric Strength | D149 | 450 V/mil | 420 V/mil |

| Result from above comparison, both products are equivalent | |||

| Property Value | ASTM Test | TPI – Amber | Competitor |

| Density | D792 | 0.0485 lb/in3 | 0.0462 lb/in3 |

| Tensile Strength | D638 | 17,000 psi | 16,500 psi |

| Tensile Modulus of Elasticity | D638 | 500 ksi | 500 ksi |

| Elongation (At Break) | D638 | 0.6 | 30-60% |

| Flexural Modulus of Elasticity | D790 | 500 ksi | 500 ksi |

| Flexural Strength | D790 | 20 ksi | 20 ksi |

| Compressive Stress | D695 | 22 ksi | 22 ksi |

| Coefficient of Friction | QTM 55007 | 0.42 | 0.42 |

| IZOD Impact (Notched) | D256 | 0.5 ft-lb/in | 0.5 ft-lb/in |

| Rockwell Hardness | D785 | M 115 | M 112 |

| Maximum Service Temperature | (Long Term) | 340ºF | 340ºF |

| Melting Point | D3418 | 410ºF | 410ºF |

| Coefficient of Linear Expansion | E831 | 31 µin/in/ºF | 31 µin/in/ºF |

| Heat Deflection Temperature, 264 psi | D648 | 400ºF | 400ºF |

| Flammability Rating | UL94 | V-0 | V-0 |

| Electric Strength | D149 | 830 V/mil | 830 V/mil |

| Result from above comparison, both products are equivalent. | |||

| Property Value | ASTM Test | TPI - Tan | Competitor |

| Density | D792 | 0.047 lb/in3 | 0.047 lb/in3 |

| Tensile Strength | D638 | 16 ksi | 16 ksi |

| Tensile Modulus of Elasticity | D638 | 630 ksi | 500 ksi |

| Elongation (At Break) | D638 | 0.4 | 0.2 |

| Flexural Modulus of Elasticity | D790 | 600 ksi | 1000 ksi |

| Flexural Strength | D790 | 25 ksi | 25 ksi |

| Compressive Stress | D695 | 20 ksi | 20 ksi |

| Coefficient of Friction | QTM 55007 | 0.32 | 0.4 |

| IZOD Impact (Notched) | D256 | 0.6 ft-lb/in | 1.0 ft-lb/in |

| Rockwell Hardness | D785 | M 105 | M103 |

| Maximum Service temperature | (Long Term) | 480ºF | 480ºF |

| Melting Point | D3418 | 644ºF | 644ºF |

| Coefficient of Linear Expansion | E831 | - | - |

| Heat Deflection Temperature, 264 psi | D648 | 320ºF | 320ºF |

| Flammability Rating | UL94 | V--0 | V--0 |

| Electric Strength | D149 | 480 V/mil- | 480 V/mil- |

| Result from above comparison, both products are equivalent. | |||

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});