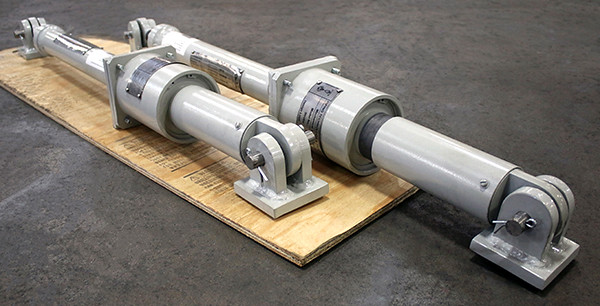

| Type: | Mechanical Snubbers |

| Size: | Length: 40-3/8” to 60-3/4″ |

| Material: | Carbon Steel | Hot-dipped Galvanized | Paint |

| Design: | 1,000 lb. – 6,000 Load | Stroke: 4″ – 5″ |

Mechanical snubbers are designed to allow pipe deflection in tension or compression when operating under normal conditions, but if an impulse load occurs (such as a water hammer, earthquake, wind, or other transient forces), the snubber becomes activated and acts as a rigid restraint to limit pipe movement. So, in general, mechanical snubbers t have two modes of operation. In passive mode, the resistance mechanism is disengaged and the snubber “free wheels” with very low resistance. In active mode, the mechanism is engaged, and the snubber limits the acceleration to a low threshold value, becoming a rigid restraint. Mechanical snubbers are used in nuclear, geothermal, and other green energy plants, as well as, the traditional chemical, refinery, and power plants. Our superior design combined with rugged construction and corrosion-resistant parts makes these units extremely reliable for a wide range of loads and movements. Typically mechanical snubbers require no maintenance. Our team of engineers can also custom design and test snubbers to accommodate your unique application.

For this particular project, in addition to the mechanical snubbers, we also supplied pre-insulated cold supports, constants, variables, and rod hangers which were delivered ahead of schedule to meet the client’s delivery needs. PT&P and its subsidiaries design and manufacture the largest range of products for piping systems globally. With today’s supply chain considerations, projects can mitigate risk by working with a single strategic supplier and ensuring timely project completion and success. Our approach is unique. The key factors are our focus on the following:

- Systems – Proprietary systems allow PT&P to manage complexity

- Engineering – 10 Industrial Engineers in Production

- Automation – extensive investment in automation

- Quality – IS0 9001 certified with a large QA team

- Training – programs to grow personnel to highly artisan/skilled functions (e.g. TIG Welding Gauge Material)

- Scale – 500+ Production Employees and over 10% of the team are engineers

- Experience – 40+ years with 5M+ products in service

PT&P REF. ORIGINAL POST 07152022