Field Service

and

Smart Maintenance Solutions

- 40+ Years of Manufacturing & Field Services

- 3 Million Pipe Supports Installed Globally Today

- 1000+ Audits Done for Pipe Supports & Expansion Joints

- World’s 1st Use of Sensors/A.I. to Pipe Supports

- 50+ Pipe Support & Expansion Joint Design & Stress Engineers

PT&P In Action

PT&P In Action

Field Services was called out to consult on how to properly support a high temperature line with extreme movement at a coal refinery.

Clamp on pipe shoe was replaced 60 feet off the ground on a critical line at a LNG plant in Florida.

A Texas chemical plant sent us their old expansion joint to be replaced with a new one reusing the existing flanges for ease of installation.

A local refinery asked for our help to size and replace another manufacturer’s failed spring hanger for a PTP equivalent in under 24 hours.

An Oklahoma Coal Power Plant contracted Field Services to install a few 54,000 lb capacity Constant Spring hangers 250 feet up on the unit where a crane could only get so close.

A proactive pipe support inspection was done before a major turnaround in Illinois, which saved them from a few major issues.

After a hurricane in Southern Louisiana, a few of our snubbers were inspected for fluid leaks and visible damage, all passed.

This Field Engineer collected information from a coal dust covered tag so that he could replace it with a PTP equivalent.

What We Do

Services

- Audit

- Installation / Repair

- Isometrics and Database

- Troubleshooting

- Stress Analysis & FEA

- Turnaround Planning

- Reverse Engineering

- Testing**

Products Supported

- Snubbers

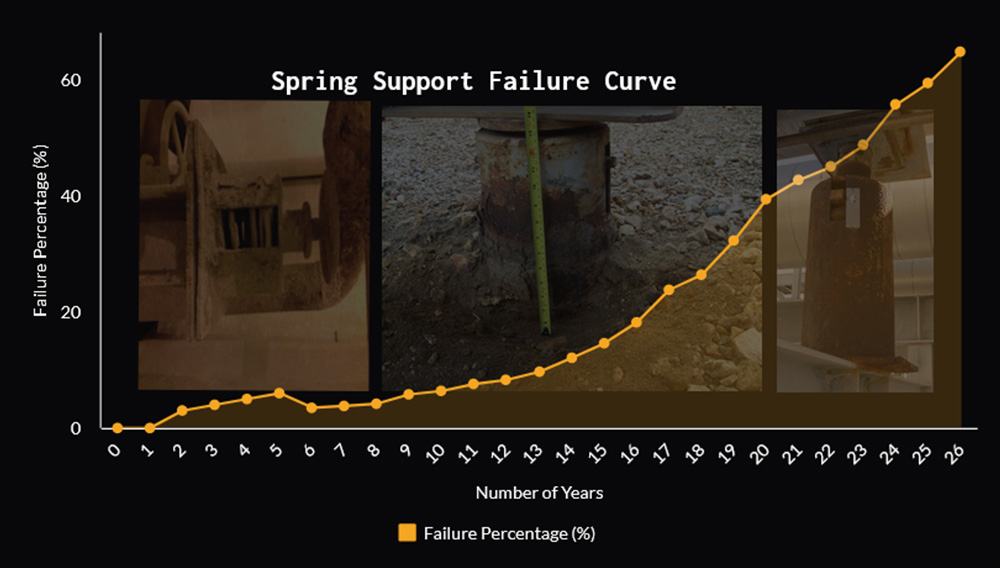

- Variables

- Constants

- Expansion Joints

- Hot & Cold Shoes

- Sway Braces

- *All Brands Supported

**Burst Testing, Helium Testing, Cycle Testing, Load Testing, Snubber Testing, Hydro-Static Testing, Bellows Fatigue Testing, Bellows Leak Test, Pneumatic Testing, Spring-rate Testing, Ultrasonic Testing, Radiography Testing, Magnetic Particle Testing, Liquid-Penetrant Inspection, Positive Material Identification (PMI)

Expertise & Service

- 24×7 Globally

- Field Team with Over 150 Years of Experience

- Access to 50+ Design Engineers

- 500+ Production Experts

- Grade A Safety Record

- Knowledge Base of 1000+ Audits

Who We Serve

- All Major Petro-Chemical

- Power Generation

- Industrial Food Production

- Semiconductor

- Automotive

- Military & Defense

- Shipping

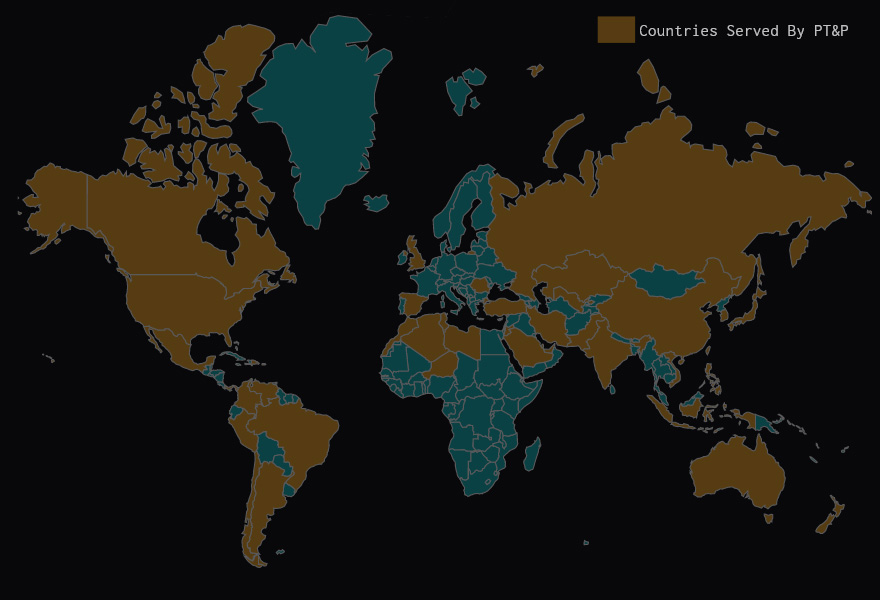

PT&P has serviced customers in 41 countries

Unparalleled Value

- On-Site Support for less than $75/day with Our Smart Maintenance Plan

- More than 30% of Critical Pipe Support Issues Missed by Generalist Engineers/Inspectors

- Over 80% of Unplanned Outage due to Pipe Supports Failure Resolved within 48 hours

- Over 20,000 Client Maintenance & Engineering Personnel Trained