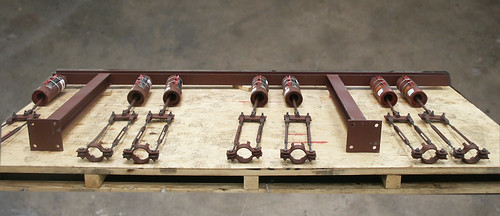

PT&P recently manufactured 1,520 PTP-2 and PTP-4 spring hanger assemblies designed specifically for a furnace application. These custom variable springs have welded components as opposed to bolted components found in standard assemblies. Due to the space limitation within the furnace, the spring coils were set in a welded housing which allows for the springs to be closely oriented within a smaller spatial envelope. The pipe hanger assemblies are made from carbon steel, consisting of variable spring, rod, and riser clamp components. Instead of galvanizing, the assemblies were coated with a red-oxide primer due to the high temperature operating conditions of the furnace. This prevents the possibility of molten zinc (from the galvanizing process) contaminating the furnace tubes.

The springs are designed for loads of 143 to 660 lbs. and for total travel ranging from 3/4 to 2″. Each assembly was pre-assembled to ensure free movement throughout the spring’s travel range before welding the bottom closure plate. Prior to shipment, all assemblies were calibrated to determine the exact spring rate and then were set to the customer’s designated cold load position. These springs are then located and installed into the furnace based on the spring rate.

Do you see a need for spring assemblies in your piping system? Get a quote today!