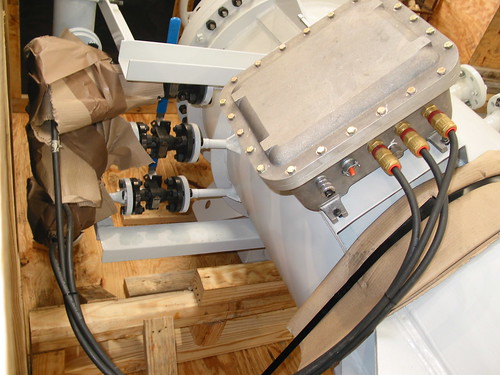

Piping Technology and Products, Inc. recently designed and fabricated two structural support units for a power plant in California.

The structural supports pipes are made of A106 Gr. B; the beam, angle and plate are made of carbon steel. They have an overall height of 11 feet with a weight of 672 lbs. The purpose of these products is to support a 3 inch intermediate pipe.

Do you see a need for structural supports in your current job? Get pricing today!