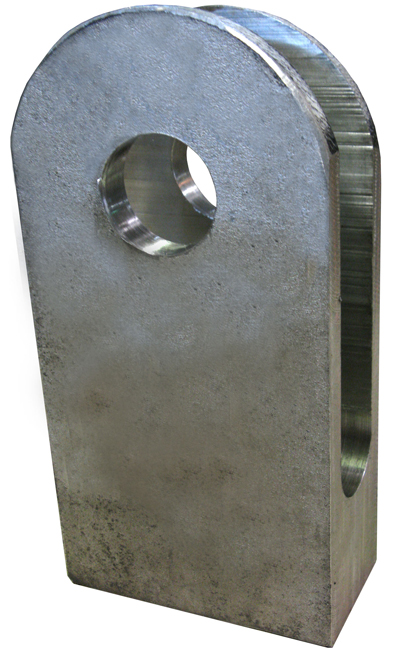

The clevis and turnbuckle pictured are each fabricated from individual solid pieces of 304H stainless steel. The 304H material, which has a maximum carbon content of 0.06%, was required because these items are designed to be used in an environment with temperatures up to 1000ºF. The customer’s specifications mandated that no welding would be allowed on either the clevises or turnbuckles. Additionally, no forgings were readily available, so blocks of 304H stainless steel were utilized in this design.

Both the clevises and turnbuckles are made to accommodate rod diameter ranges between 1-1/4″ to 1-3/4″. These components have a maximum load capacity of 18,600 lb. The clevises measure 3″ thick x 5-1/4″ wide x 10-5/8″ tall. The turnbuckles measure 2″ thick x 4″ wide x 9-1/4″ tall. Prior to fabrication, each component was modeled using finite element analysis to determine that stress levels are within the acceptable range.

Do you require some pipe support hardware for your project? Get pricing today!