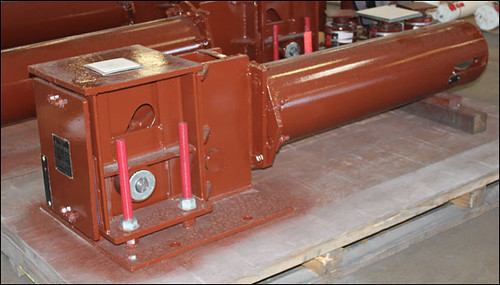

PT&P manufactured B type constant spring supports for a hydrocracker application at a refinery in Port Author, TX. These custom designed constants are 83″ x 41″ x 20″, and designed to support a 53,000 lb. riser pipe through two trunnions. The constants are designed for an operating load of 26,700 lb. with 10-1/2″ of total travel. They are fabricated from A36 carbon steel and underwent standard load and travel testing prior to shipment.

Read MoreBlog Category: ENGINEERED SPRING SUPPORTS

G-Type Variable Spring Supports Designed for a Chemical Plant

PT&P designed G-Type variable spring supports for a chemical plant in Texas. The variables are comprised of two standard spring housing joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions which allows for use in applications with limited space or interferences. The variables are fabricated from carbon steel with a hot-dipped galvanized finish. The assemblies were designed for a total operating load of 23,522 lb. with a downward design travel of 3/8″. Each assembly underwent a standard load test prior to shipment.

Read MoreVariable Spring Supports Custom Designed for a Furnace Application in an Ammonia Plant

PT&P custom designed variable spring supports for catalyst tubes in a furnace for an ammonia plant in Canada. The furnace springs are fabricated from carbon steel and painted with a red-oxide primer to help prevent corrosion. This project required special coils that were within +/- 5% of the calculated spring rate. Over 245 springs underwent calibration test prior to shipment. PT&P has been supplying furnace springs for over 25 years and can customize them to meet your specifications.

Read MoreVariable Spring Hangers Designed for an Oil Sands Expansion Project

Piping Technology & Products designed and fabricated 107 variable spring hanger assemblies for an Oil Sands Expansion Project in a central processing facility in Canada. We fabricated these C-type variable springs from hot-dipped galvanized carbon steel. The design loads range from 3,343 lb. to 3,417 lb., and each assembly underwent a series of tests and detailed quality control inspections prior to shipment.

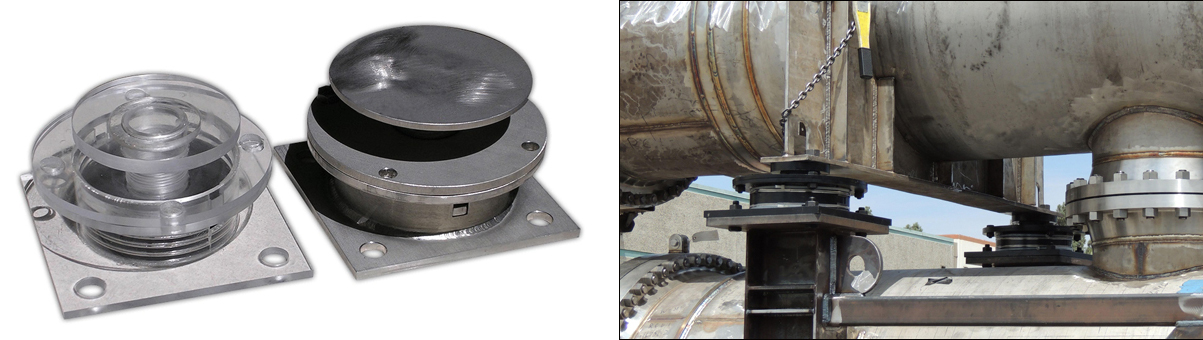

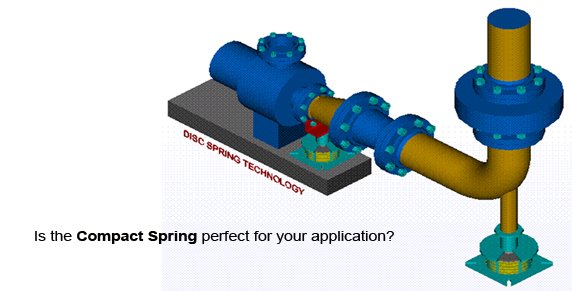

Read MorePT&P partners with Disc Spring Technology to offer you the Compact Spring Support

The compact spring is ideal for applications with large loads and limited space.

The compact spring is ideal for applications with large loads and limited space.

– Minimizes excessive loads on sensitive equipment

– Same load for smaller working range while consuming 25-50% less space

– Ideal for locating under equipment flanges

– Reduces design time, maintenance cost and accidents

>> Get a quote now or email us your questions at info@devptp.fronekgrp.com

These springs are the solution for satisfying excessive nozzle loads for load sensitive equipment, such as pumps, compressors, turbines, blowers, heat exchangers, pressure vessels and storage tanks. In addition, the entire spring support can be made from corrosion resistant stainless steels or other suitable alloys making it ideal for combating aggressive environments like seawater, marine air and harsh chemicals.

View the DST Catalog for more details

Read MoreF-type Variable Spring Supports Designed for a Petroleum Facility

PT&P designs thirty F-type variables spring supports for a petroleum facility in Canada. The springs are fabricated from carbon steel and with a hot-dipped galvanized finish. The assemblies are internally guided and have a 3,455 lb. operating load. A standard travel test was conducted on the variables prior to shipment.

Read MoreG-Type Variable Spring Supports Designed for a Paper Manufacturing Plant

PT&P designed G-Type variable spring supports for a paper manufacturing plant in Minnesota. The variables are comprised of two standard spring housing coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions which allows for use in applications with limited space or interferences. The variables are fabricated from carbon steel with a hot-dipped galvanized finish. The assemblies were designed for a total operating load of 1,348 lb. with an upward design travel of 0.8013″. Each assembly underwent a standard load test prior to shipment.

Read MoreU-Type Constant Spring Supports Designed to Support Ducts in an Acid Plant

U-Type constant spring supports were designed to support ducts in an acid plant. The constants are fabricated from carbon steel, galvanized and painted for extra protection against corrosion. The U-type constants are designed to support piping from below. The base plate is 25-7/8″ wide and bolted directly to the top of the steel or floor. The assemblies measure 84″ in length and 22-1/2″ in height. They only have vertical movement subjected by 6-1/2″ total upwards travel and are capable of supporting a 13,489 lb. load. The constants underwent standard spring testing prior to shipment.

Read MoreVariable Spring Supports Designed for a Coker Unit in an Oil Refinery

PT&P designed and fabricated D-type variable spring supports for a coker unit in an oil refinery in the UAE. The variables are designed for a special pipe diameter of 4-3/4″. The cans are fabricated from electro-galvanized carbon steel, and the springs are coated with an electrophoretic epoxy coating. The variable springs are designed for 2.79″ of upwards movement, 300 lb. at 81°F. Standard load test and a spring rate test was performed prior to shipment.

Read MoreG Type Constant Spring Supports Designed for a Power Plant in Mississippi

PT&P custom designed 16 G type constant spring supports for a power plant in Mississippi. The constants are comprised of two standard constant spring housing sub-assemblies joined together with an intermediate bridge assembly. They also include welded beam attachments, rods and hex nuts. The assemblies are designed to support pipes ranging from 80″ – 96″ in diameter. Standard load and travel tests were performed prior to shipment.

Read More