PT&P custom designed C-type constant spring supports for an oil refinery in the Virgin Islands. They are fabricated entirely from 304 stainless steel to support piping in a highly corrosive environment. The design loads are 7,000 lb., 9,500 lb., and 11,000 lb. with movements of 2-1/2″ and 3″. The constants measure 29″ L x 22″ W x 20″ H. Standard load and travel testing was conducted prior to shipment.

Read MoreBlog Category: ENGINEERED SPRING SUPPORTS

New Webinar: Pipe Supports for Beginners- Constants & Variables

View the recording at: Webinars

This webinar series was created to explain the basic principles of different types of pipe supports in the simplest way possible. It is geared towards “non-engineers” who want to have a better understanding of pipe supports. This particular presentation will give you a brief introduction to pipe supports and will then solely concentrate on constant and variable spring supports. It will explain the various designs, applications, and details of each support using simple terms and a lot of visual aids. The presentation will conclude with general guidelines of the maintenance and ordering process of constants and variables.

Read MoreOver 40 Constant Spring Supports Designed to Support Production Pipes

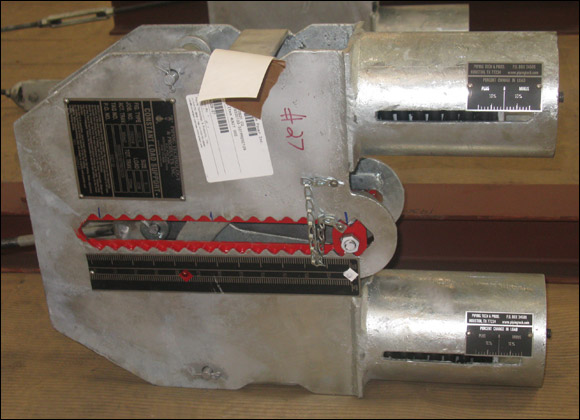

Over 40 constant spring supports were custom designed to support production pipes in an oil refinery. This picture shows a Fig. 200 U-Type constant spring support.

This picture shows a Fig. 100 B-Type constant spring support.

The constants range in size from 22″ to 30″ in height, 35″ to 85″ in length, and 12″ to 31″ in width. Their load capacities range from 1,800 lb. to 20,800 lb. with a vertical movement ranging from 7″ to 11-1/2″. All constants were fabricated from A-36 carbon steel and painted with a 3-coat paint system. Each constant went through standard load and travel testing per MSS Standards prior to shipment.

Read MoreVariable Spring Hanger and Structural Steel Assembly for a Solar Electric Generating System

These variable spring hangers were designed for a 10″ pipe line in a solar electric generating system. All assemblies were fabricated from A-36 carbon steel with a hot-dipped galvanize finish. The picture on the left shows a structural steel assembly supporting a PTP-1 variable spring and a Fig.80 heavy 3-bolt clamp designed for a 3,789 lb. load. The picture on the right shows two PTP-2 variable spring hangers welded to a structural steel beam designed for a 675 lb. load. Each pipe hanger assembly went through standard load and travel testing prior to shipping.

Read More200 E-Type Horizontal Constant Spring Supports for a Fired Heater Radiant Manifold

These 200 E-Type horizontal constant spring supports are fabricated from A-36 carbon steel with a hot-dipped galvanize finish. The pins made for constants operation are A-322-4140 high strength carbon steel. The constants range in size from 22-3/4″ to 26-1/4″ heights, 60″ to 90″ lengths, 18″ width, and 19-1/2″ to 23-1/2″ in coil housing diameters. They are designed for 23,160 lb. to 33,700 lb. loads and 6-1/2″ to 14″ of total travel. A total of sixteen assemblies were custom designed for a fired heater radiant manifold. Each pipe hanger assembly went through standard load and travel testing prior to shipping.

Read MoreVariable Spring Supports with Permanent Upward Travel Stops

Five total assemblies of custom designed variable spring supports were made for an oil refinery in the United Arab Emirates. These springs required a permanent upward travel stop. The spring cans were supplied with PTFE and polished stainless steel slide plates attached to carbon steel load flange. All materials used were domestic (from the U.S.). The springs were tested for lateral loads. The spring coils were stress tested and can withstand temperatures of 176°F (80°C), with a downward movement of 30mm – 45mm.

Read MoreBig Tons with W-Beams as Stilts

Stilts using W-Beams were added to these big ton variable assemblies in order to meet height requirements for an oil refinery in Port Arthur, TX. Entirely fabricated with carbon steel, these big tons measure 50 1/2″ – 70″ L x 18″ – 22″ W by 37″ H and are capable of supporting loads up to 113,734 lb with an upward travel range of .076″ – .816″. Permanent travel stops were later installed in order to prevent any chances of downward shift.

Read More113 F-Type Variable Spring Cans with PTFE Slide Plates

These F-Type variable spring cans were designed with PTFE, 25% glass filled slide plates for a local oil refinery. Slide plates are used to reduce the friction between the load flange of the spring and the pipe support. This allows for easier adjustment of the spring’s installed height. These variables include external travel stops. The external travel stops are sometimes referred to as universal travel stops and can be utilized to adjust the installed load (also called the cold load) to other installed loads within the working range of the spring. 113 variable springs were supplied for this job. The variables have an installed load ranging from 95 lb. to 11,000 lb. and an operating load ranging from 90 lb. to 10,703 lb. They are part of a plant expansion and will be used to support horizontal piping in an oil refinery.

These F-Type variable spring cans were designed with PTFE, 25% glass filled slide plates for a local oil refinery. Slide plates are used to reduce the friction between the load flange of the spring and the pipe support. This allows for easier adjustment of the spring’s installed height. These variables include external travel stops. The external travel stops are sometimes referred to as universal travel stops and can be utilized to adjust the installed load (also called the cold load) to other installed loads within the working range of the spring. 113 variable springs were supplied for this job. The variables have an installed load ranging from 95 lb. to 11,000 lb. and an operating load ranging from 90 lb. to 10,703 lb. They are part of a plant expansion and will be used to support horizontal piping in an oil refinery.

Read More

Big Ton Variable Spring Supports with Rollers Designed to Support a Load up to 60,000 lb.

These are custom designed big ton variable spring assemblies manufactured for a chemical plant in Brazil. They are fabricated from A-36 carbon steel, with monel rods, nuts and hardware. They measure 18″ L x 26″ H x 26-1/2″ W and are capable of supporting loads up to 60,000 lb. with down travel of .52″. These big tons employ the use of rollers for adequate mobility and are painted to protect against corrosion.

Read MoreSpecial E-Type Constant Springs Designed to Support Boiler Trim Piping

Special PTP-100 E-Type constant spring supports were custom designed to support boiler trim piping for steam generating in an upper thermal power unit. The constants measure 5-3/8″ W x 16-3/4″ L x 23-1/2″ H. They are highly customized to meet the customer’s space requirements and operating method to eliminate the hanger rod from shifting, allowing it to move only vertically while going from cold to hot position. Standard constant assemblies of this size, are about 50% larger and the hanger rod would shift horizontally as the travel reaches the hot position. These constants are designed for loads ranging from 72 lb. to 92 lb. and movements ranging from 10″ to 11-1/2″ downward. Standard load and travel tests were conducted prior to shipment

Read More