We just posted a new video that discusses our spring loading procedure of standard variable springs. Watch our field service representative talk you through the process of loading a variable spring before it is shipped.

We just posted a new video that discusses our spring loading procedure of standard variable springs. Watch our field service representative talk you through the process of loading a variable spring before it is shipped.

These PT&P 200 series constants are fabricated from A36 carbon steel. The 200-A constants measure 18.5″w x 20″H x 65″L and will support a 22,200 lb. load. They are modified to avoid interference with the structure by shortening the frame. The 200-C constants measure 18.5″w x 29″H x 80″L and will support a 32,000 lb. load. The constants have specially fabricated lugs to allow for a 3 ton trolley to connect with it.

Do you have a need for constants in a current or upcoming project? Let us price them for you!

PTP-2 Type-G variable spring support assemblies were designed and fabricated for an expansion project at an oil refinery. The G-type spring is comprised of two standard variable spring housing-coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions, which allows for use in applications with limited space or interferences. This particular assembly was provided with extra large channels because the specified C-C dimension of 59″ exceeded the maximum (48″) of our standard G-type variable springs. The housings, internal components and channels were fabricated from carbon steel, and spring steel was used for the coils. The assembly was designed for a total operating load of 24,014 lb. with a design travel of 0.76″ upward.

PTP-2 Type-G variable spring support assemblies were designed and fabricated for an expansion project at an oil refinery. The G-type spring is comprised of two standard variable spring housing-coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions, which allows for use in applications with limited space or interferences. This particular assembly was provided with extra large channels because the specified C-C dimension of 59″ exceeded the maximum (48″) of our standard G-type variable springs. The housings, internal components and channels were fabricated from carbon steel, and spring steel was used for the coils. The assembly was designed for a total operating load of 24,014 lb. with a design travel of 0.76″ upward.

Want to learn more about variable springs? Watch an instant recording of a past variables webinar.

Don’t know your cold / installed load? Use our new web-based spring sizing calculator to find all the springs that can fit your design parameters.

These figure 100 C-type constant springs were manufactured from A36 carbon steel for an oil refinery in Canada. Each constant was designed for 7″ of travel with a load of 35,144 lb. They measure 21.5″ W x 42″ L x 80″ H, and were specially designed to match a competitor’s dimensions in order to fit in the required application.

Do you require constant spring supports for your piping system? Get pricing today!

Read More

——————————————————————————————————————————

A “U-Type” and 6 “C-Type” constant spring supports were designed to support piping in a corrosive environment located off-shore in Malaysia. The U-Type measures 21″ x 25″ x 57″ and C-Types range in size from 11-5/8″ x 17″ x 4″ to 18-3/4″ x 32″ x 80″.

The constants are fabricated from A36 carbon steel with a fluorocarbon coating on the pins. The frame, housing, and all components were coated with a 3-coat paint system to resist corrosion. Standard load and travel tests were performed prior to shipping the constants on a rush basis.

Want to learn more about constant springs? Instantly view a past webinar on constants now!

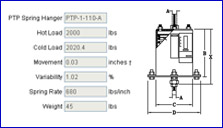

An assortment of standard variable spring supports were manufactured ranging in size from 8-5/8″ to 12-3/4″ dia. with installed heights ranging from 9-7/16″ to 18-1/8″. The F-Type pipe hanger assembly is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The various springs shown are designed for operating conditions ranging from loads of 1750 lb. with .02″ travel to 21,280 lb. loads with .13″ travel. As with all of our variable supports, these were quality checked with a 100% spring coil deflection test and a load cell calibration to set the assembly at the prescribed installed load.

Do you see a need for variable springs in your piping system? Let us price them for you!

Ever wonder what makes a constant spring support different from a variable spring support? How does each one function? How do they support loads and allow for movement in a pipeline? Check out our new spring support article that provides all the answers to these questions and more.

Want to learn more about constants? Instantly view a past constants webinar now!

Read MoreThis big ton spring support measures 40″ length x 36″ width x 43″ height. It is composed of a carbon steel frame, neoprene coated spring steel coils, and has a hot-dipped galvanize finish. It also includes a guided load table to ensure stability when supporting the maximum load of 93,000 lb. Standard load and travel tests were performed prior to shipping.

Do you see a need for big tons springs in your piping system? Get pricing today!

This 200 E-Type horizontal constant spring support is fabricated from carbon steel with a

hot-dipped galvanize finish. It is designed for a 54,020 lb. load with a total travel of 15.5″. The 3-bolt pipe clamp is designed for a 26″ diameter pipe and is coated with a red oxide primer. Each pipe hanger assembly went through standard load and travel testing prior to shipping. PT&P will design and fabricate any size constant spring support in addition to the sizes listed in our catalog.

Want to learn more about spring supports or clamps? Instantly view a past webinar now!