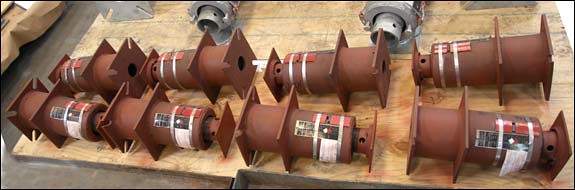

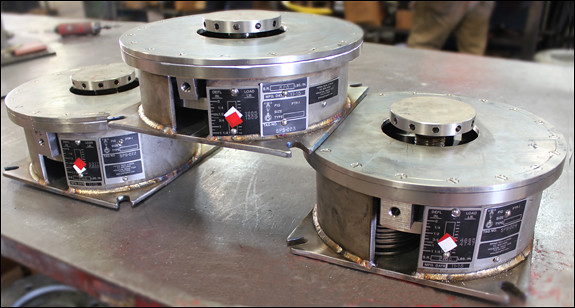

| Type: | Variable Spring Supports |

| Material: | Alloy 2205 Duplex/SAE 5160H |

| Design: | Operating Load up to 3,597 lbs./Operating Temperatures of -15-200°F |

| Testing: | Standard Load & Travel Tests |

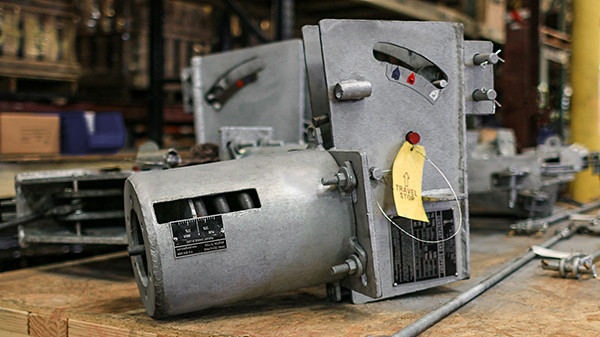

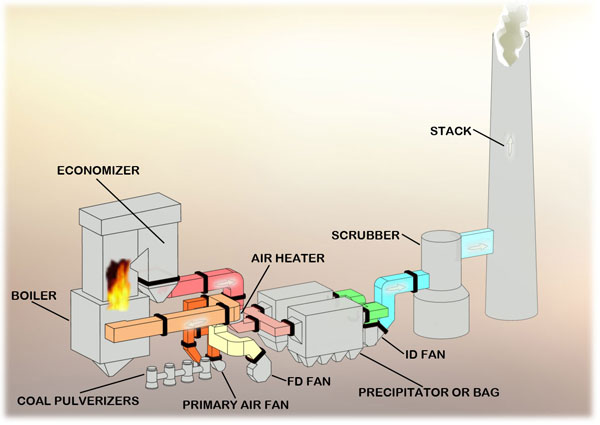

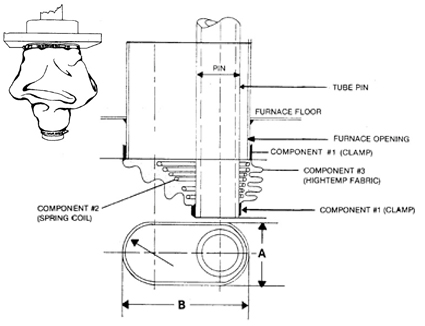

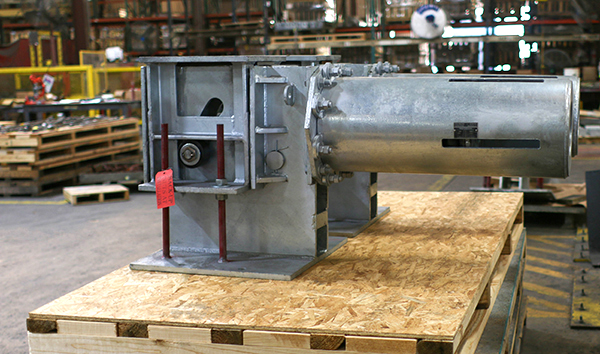

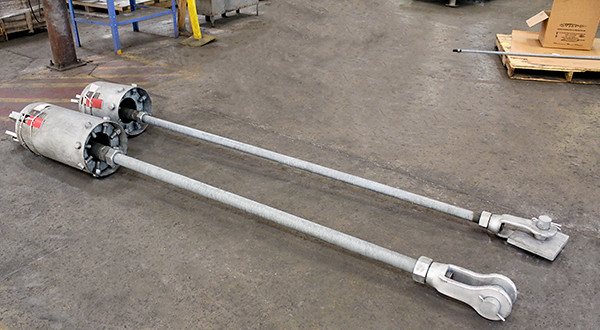

PT&P manufactured these custom variable spring supports for a floating LNG platform in Singapore. The spring housings are fabricated with alloy 2205 duplex, and the coil is manufactured from – SAE 5160H to help prevent corrosion due to sea salt. The variables installed heights range from 10-3/4″ to 12-1/16″ and are designed for an operating load of up to 3,597 lbs. Also, load tests were performed at operating temperatures of -15°F, along with liquid penetrant testing of the welds. These variable springs are also designed to suit a highly corrosive environment such as sea salt. They can operate in temperatures ranging from -14 to 200°F without compromising their load-carrying capacity. We offer a full range of pipe supports and expansion joints for offshore applications, including floating platforms for cryogenic systems for offshore LNG transfer, both for ship-to-ship and ship-to-shore. Our team of engineers and field service technicians have assisted in offshore diving examinations to both inspect and recommend solutions to help solve emergency needs.

As the floating LNG market continues to grow at a rate of almost 5% year over year, it is evident the increased demand for clean energy is the driving factor. Piping Technology and Products and its subsidiaries are well-positioned to support the global pivot to renewable and clean energy needs. In the last year alone, we designed and delivered products and services in most associated sectors, including solar, wind, water, geothermal, bioenergy, nuclear, hydrogen & fuel cell sectors worldwide.

PT&P REF. ORIGINAL POST 01022018

Read More