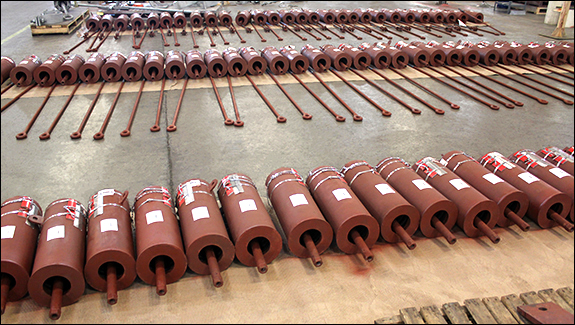

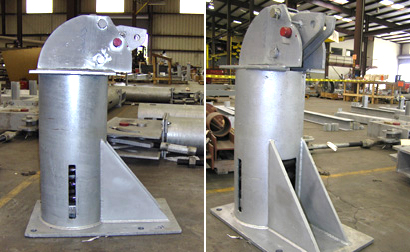

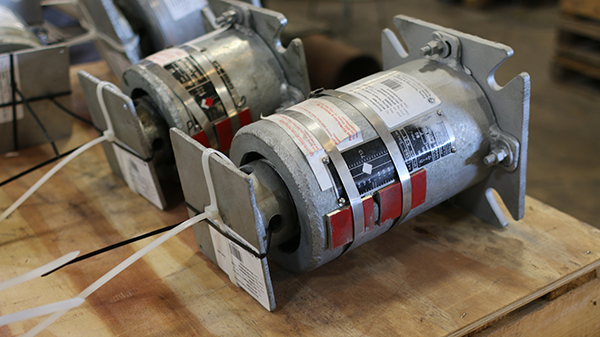

| Type: | Constant Spring Supports |

| Size: | 15-¼” W x 17″ H x 46″ L with 9-¼” OD |

| Material: | Carbon Steel | Hot-dipped Galvanized |

| Design: | 2,379 lb. Load | 10″ Upward Movement |

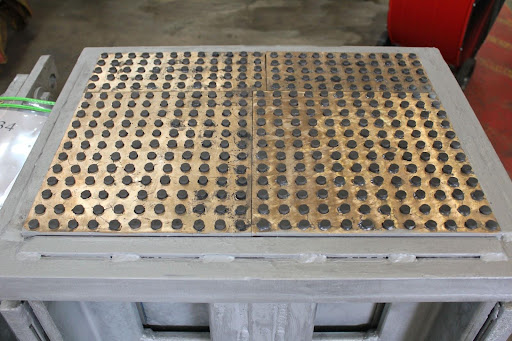

PT&P custom designed and manufactured constant spring supports for a chemical plant in Singapore. The constants are fabricated from A36 carbon steel and include alloy coil springs. The dimensions are 15-¼” W x 17″ H x 46″ L with 9-¼” OD. They were designed for an operating load of 2,379 lb. and movement of 10” upward and were specially designed to incorporate “telescoping spring coil housings ” and painted to protect against corrosion. Standard load and travel tests were performed prior to shipment. As part of the standard quality control process, we test every constant that we build before it is shipped. We are ISO-9001:2015 Certified by DNV GL. Last year we built over 1500 constants alone for our customers. Some were designed to support loads up to 150,000lbs with movements over 48 inches.

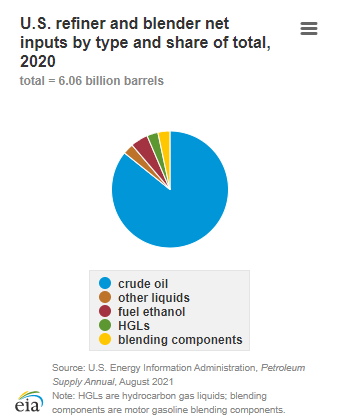

These specific constants were for a plant that manufactures industrial gasses such as hydrogen, carbon monoxide, and synthesis gasses. Constant spring assemblies are used in a variety of applications ranging from CDU (crude distillation units), hydrocracking units, RFCC (residual fluid catalytic cracking), naphtha hydrotreater and hydrodesulfurization units (also known as alkylation units), and sulphuric acid regeneration (SAR) units in refineries, LNG, Geothermal, Coker units, HRSG units, and other facilities where there is substantial thermal growth in the piping. They can be configured to accommodate horizontal or vertical movement.

Constants use a spring coil (or set of coils) to accommodate pipe movement from the initial (installed) condition to the final (operating) condition of the piping system. For all constant spring supports there is no difference in the load to be supported. Instead, these spring supports are designed to accommodate movement due to thermal expansion or contraction. PT&P has set up its manufacturing department to offer an unparalleled set of customization options with minimal impact on delivery timeframes. In addition to our standard (hot-dipped galvanized, neoprene coated spring coils) variable spring supports, we can customize any material, finish, dimension, load, load adjustment, travel, travel stops, and provide sensors for remote monitoring.

PT&P REF. ORIGINAL POST 12112018

Read More