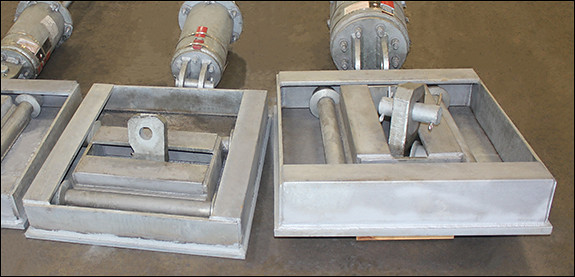

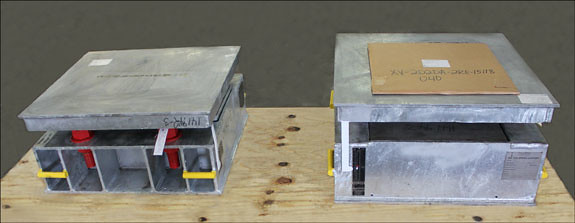

PT&P custom designed big ton spring supports for a propane dehydrogenation facility in Texas. The components within these assemblies include the spring housing, load columns, travel stops, spring coils and lifting lugs. While both assemblies measure 42” x 24” x 26-1/2”, they were each modified based on independent specifications for operating loads and movement. The first will accommodate a load of 94,261 lb. and 0.085” of movement, while the second will accommodate a load of 102,219 lb. with 0.08” of movement.

This type of support is ideal for applications, such as pressure vessels, that combine very heavy loads with thermal expansion because of the stability they provide. The big tons were tested in the load cell to insure proper operation throughout the entire working range of the coils.

Read More