Blog Category: ENGINEERED SPRING SUPPORTS

300 Variable Spring Supports Designed for a Furnace Application

PT&P designed and fabricated 300 variable spring supports for use in a furnace within a methanol processing facility in Mexico. We manufactured the ”housing” of these variable springs using seamless pipe (in order to prevent the springs’ coils from rubbing against the ”weld seam” of a standard pipe) so that the exact spring rate (+/- 5%) can be calculated without discrepancies or variations. The reason that an accurate spring rate is important is because furnace springs function as a ”scale” in order to determine the weight of the radiant coils within the unit. These springs are coated with red oxide primer to protect against corrosion. We manufactured these furnace spring assemblies for an operating load of 1,036 lb. and a movement up to 8 1/2″. Each spring is traceable to test data and tagged with its’ unique spring rate along with other standard information use for identification.

Read MorePipe Supports and Expansion Joints for Furnace Applications Webinar

This webinar is over, view the recording in the webinar archives

Join us for this Webinar focusing on the unique design aspects of pipe supports and expansion joints operating in furnace applications. See how these non-standard designs impact the overall construction and fabrication processes. Learn the differences between standard supports and those specifically used in furnace applications. View the in-depth testing processes and learn what to watch for during inspection and maintenance intervals.

Join us for this Webinar focusing on the unique design aspects of pipe supports and expansion joints operating in furnace applications. See how these non-standard designs impact the overall construction and fabrication processes. Learn the differences between standard supports and those specifically used in furnace applications. View the in-depth testing processes and learn what to watch for during inspection and maintenance intervals.

The featured presenter, Jerry Godina has over 15 years experience as a pipe support designer and manages PT&P’s engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

Read More

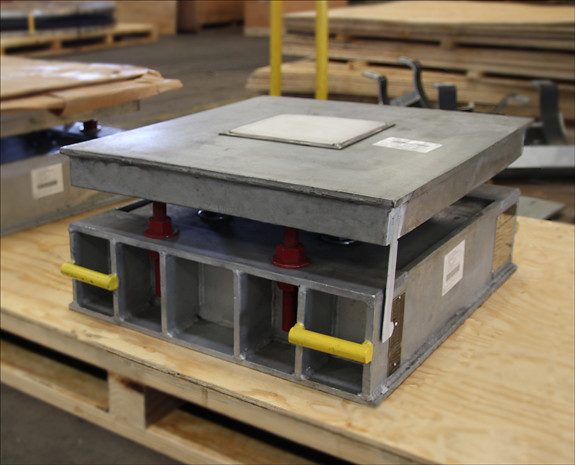

Big Ton Spring Supports Designed to Support a Pressure Vessel

These big ton spring supports were custom designed for an LNG plant in Australia. These units were designed with PTFE, 25% glass filled slide plates, and will be used under the saddle supports of a horizontal pressure vessel. The big tons were selected due to a combination of confined space, heavy loads, and thermal expansion. The units measure 28-3/8″ x 25-3/8″ x 13” and are capable of supporting a load up to 11,488 lb while accommodating a down travel of 0.31 inches.

Read MoreConstant Spring Supports Designed for a Power Plant in New Mexico

PT&P fabricated constant support assemblies for a power plant in New Mexico. The constant assemblies will be used in conjunction with structural supports also provided by PT&P. Operating loads range between 7,000 lb. and 20,000 lb. and designed for movements from 10-1/2″ to 12″. All thread rods were coated with rust prevention compound and the constants were painted with Intergard® 475 HSS. The travel stops are wired to the constants frame and can be reused to lock the constant, preventing travel during plant maintenance or shutdowns. Standard load and travel tests were completed according to MSS standards prior to shipment.

Read MoreSign-up for our next Webinar on Variable Spring Supports

This webinar is over, view the recording in our webinar archives

![]() Variable Spring Support Design, Size Selection, Installation & Maintenance Webinar

Variable Spring Support Design, Size Selection, Installation & Maintenance Webinar

This Webinar will focus on the different types of variable spring supports and big ton variable spring supports. Learn about the special features available, in addition to the design of a variable support. View how the different coil configurations produce a unique response to an applied load and see how a spring assembly is loaded. Discover the basic steps in selecting a hanger design and the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to replace or re-calibrate a variable spring support, as well as adjustments, shutdown and isolation procedures.

Read More

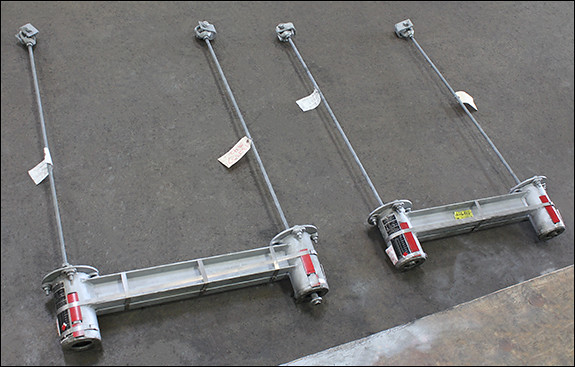

G-Type Variable Springs Support Designed for an LNG Facility

PT&P designed these G-Type variable spring support assemblies for an LNG facility in Saudi Arabia. The variables are comprised of two standard spring housing joined together with an intermediate bridge assembly. They are designed for an upwards travel range of 0.078″ to 0.118″. The variables were fabricated from carbon steel with a hot-dipped galvanized finish. Standard load and travel testing was completed prior to shipment.

Read MoreCompact Spring Supports Designed for a Pump Application in Wyoming

These compact spring supports were custom designed and built within 4 weeks to support a pump for a facility in Wyoming. The housing was fabricated from A-36 carbon steel and hot-dipped galvanized to protect them against corrosion. The disc springs are engineered using the stainless steel Belleville disc springs designed for large loads but small movements. In this case, the springs are designed to support a load of 11,137 lb. and movement of 0.018″ (upward). Each assembly underwent load testing prior to shipment.

The compact size and resistance to corrosion attributes of these compact spring supports make them ideal for placement under the discharge piping of a pump at this facility. By using these compact spring supports directly on the pump, excessive thermal loading on the pump’s discharge nozzle is resolved and brings it within the pump manufacturer’s allowable limit, so the pump will operate safely, as intended which also results in extended life and low maintenance.

Read MoreRegister for the next Webinar: Engineered Spring Supports (Practical, Hands-on Approach)

This webinar is over… view the recording at: https://devptp.fronekgrp.com/resources/media/webinars/

Live Webinars are worth 1 PDH Credit for TX Professional Engineers

Learn how the theoretical applications of spring supports are put into use in the real world. We will start with a review of the working principles of both variable and constant springs. See how brand new spring looks at delivery, and review installation guidelines. Learn the key points to review through the total installation process and subsequently when the springs are in operation. See how to determine if springs need adjustments, re-calibration, refurbishment or replacement. View in field examples, shutdown and isolation procedures. See the selection process required when there are significant changes to the operating condition.

The featured presenter, Jerry Godina has over 16 years experience as a pipe support designer and manages PT&P’s engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

Read More