PT&P designed 100-F type constant spring supports for an oil refinery in Alabama. These custom constant spring supports are 32” x 12” x 23.5” and designed to support an operating load of 650 lb. with 14” of total travel. The constants are fabricated from A36 carbon steel and the coil is from 5160H alloy material. Standard load and travel testing were completed to ensure the quality and performance of these constants.

Read MoreBlog Category: ENGINEERED SPRING SUPPORTS

Custom Variable Spring Supports Designed for a Furnace Application in an Ammonia Plant

Custom Variable Spring Supports Designed for a Furnace Application in an Ammonia Plant.

PT&P custom designed variable spring supports and hangers for a furnace application in an ammonia plant. The furnace springs are fabricated from carbon steel and painted with a red-oxide primer to help prevent corrosion. The spring supports are designed to support loads ranging from 400 lb. to 12,500 lb. Over 150 spring coils underwent calibration test prior to fabrication and insertion into the variable support housing to ensure variance of less than 5%.

Read MoreCompact Disc Spring Support Designed for a Heat Exchanger Application

Compact Disc Spring Support Designed for a Heat Exchanger Application

In this application, the heat exchanger (vertical vessel), has thermal movement of 1/4″, vertically. As it expands thermally, the vessel lifts off its support structure and additional forces at the vessel’s lower nozzle are created. With many heat exchangers, as well as other process equipment, the space between the support structure and equipment is restricted. In this case, the space between the cantilever clamp attached to the vessel and the support structure is limited to only 5.1″. This lack of space is unsuitable for placing the conventional spring supports which require more space.

The Compact Disc Spring support is designed to support large loads in small confined spaces with limited thermal movement (from 0 to 3/4″). By supporting the vessel with Disc Springs, the thermal movement is allowed (or relieved), which helps reduce the excessive loads and local stress on the nozzles. This results in compliance with the ASME Piping and Vessel Codes. Due to a corrosive chemical plant environment, the two Compact Disc Spring supports were supplied with engineered 17-7PH Stainless Steel Belleville Disc Springs to combat corrosion.

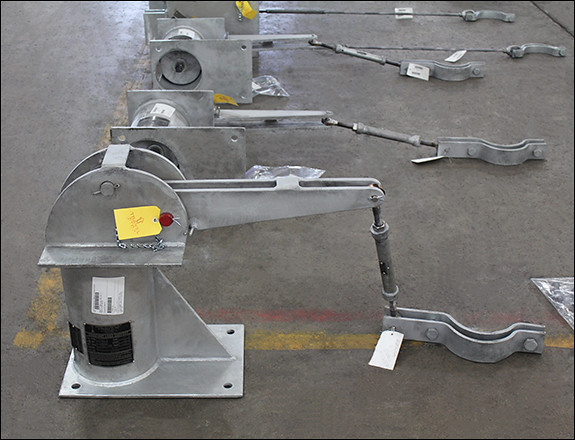

C-Type Variable Spring Supports Designed for a Power Plant

PT&P designed C-Type variable spring support assemblies for a power plant in Louisiana. They are designed for operating loads ranging from 1,319 to 2,800 lb. with an upwards travel ranging from 0.11″ to 0.34″. The variables were fabricated from carbon steel with a hot-dipped galvanized finish and standard load and travel testing was completed prior to shipment

Read MoreF-Type Variable Spring Supports Designed for a Chemical Processing Plant

PT&P manufactured F-type variable spring supports for a chemical processing plant in Texas. The variables are designed with an internal guide and for a movement of 0.09″. They are designed for a 5,350 lb. cold load and 5,450 lb. hot load. Because these springs had to be capable of withstanding a hydro-test in excess of 33,000 lb. (which substantially exceeded the standard maximum hydro-test of 18,000 lb.), special collars were used in conjunction with the standard travel stops. These collars are designed to absorb the large hydro load by relying on the high strength characteristics of the load flange and housing components of the assembly while essentially bypassing the threaded internal components.

Read MoreConstant Spring Supports Designed for a Steam Methane Reformer

PT&P manufactured Fig. PTP 100-E constant spring supports for a steam methane reformer plant project in Thailand. The constant springs are designed for a pipe operating temperature from 650°F to 1250°F and an operating load of 3,355 lb. with a movement of 13″ upward. The constants are fabricated from carbon steel and painted with an epoxy for high temperatures. Standard load and travel test were completed prior to shipment.

G-Type Variable Spring Supports Designed for a Coker Replacement Project

PT&P fabricated PTP-6 G-type variable spring supports for a coker replacement project in Kansas. The variables are comprised of two standard spring housing joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions which allows for use in applications with limited space or interferences. They are 50″ in length, designed for an operating load of 15,000 lb. and fabricated from carbon steel with a hot-dipped galvanized finish. All variable assemblies underwent standard load and spring testing prior to shipment.

Read MoreCustom Designed Upthrust Constant Spring Supports

PT&P designed Fig. PTP 200-U upthrust constant spring supports modified to accommodate an increased installed height. PT&P fabricated these constant assemblies from A36 carbon steel. They were designed for temperatures up to 185°F, and a load of 15,737 lb. The constants are capable of a downward total travel of 2″ and are 61″ L x 25″ W x 39″ H. Standard load and travel tests were conducted prior to shipment.

Read MoreF-Type Variable Spring Supports Designed for an LNG Facility

PT&P manufactured F-type variable spring supports for an LNG facility in Colorado. The variables installed heights range from 10-5/8″ to 21-1/16″. The F-Type pipe hanger assembly is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The various springs shown are designed for operating conditions ranging from loads of 633 lb. to 6510 lb. As with all of our variable supports, these were quality checked with a 100% spring coil deflection test and a load cell calibration to set the assembly at the prescribed installed load.

Read MoreF-Type Variable Spring Supports Designed with Stainless Steel Slide Plates and Permanent Travel Stops

PT&P custom designed F-type variable spring supports for an oil refinery in Saudi Arabia. These assemblies range in height from 14-1/4″ to 39-3/8″ and include stainless steel slide plates and upper permanent travel stops. Some of the variables include an additional pipe extension to meet the installation height requirement. The variables are fabricated from carbon steel and painted with a special paint to resist corrosion. All variable assemblies underwent a standard variable spring test prior to shipment.

Read More