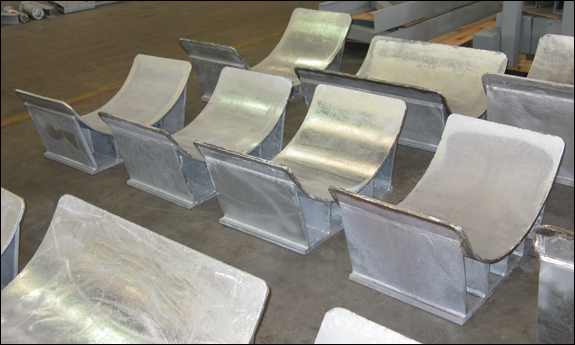

| Type: | Heavy Duty Pipe Saddles |

| Design: | 60″ Dia. | 23-5/8″ Length | 5-18″ from BOP |

| Material: | Carbon Steel with a HDG Finish |

| Testing: | Visual | Sample Pipe | Dimensional |

Piping Technology & Products, Inc. designed and manufactured these heavy duty pipe saddles for the Ethylene Plant Project in Texas. The saddles are fabricated from A36 carbon steel with a hot-dipped galvanized finish and designed to support pipes up to 60″ in diameter. They measure 23-5/8″ in length and 5-1/8″ from BOP. Standard Q.C., visual inspection with a sample pipe and dimensional tests were performed prior to shipment.

Read More