PT&P provided a cable tray support rack to a groundwater treatment facility in California. Groundwater remediation is a process whereby groundwater is purified by removing pollutants and containments rendering the water useful for crop irrigation and industrial processes. Groundwater remediation techniques can include but are not limited to, oxygen gas injection, dual-phase extraction, membrane separation, carbon absorption, and chemical oxidation. Cable trays, used in this facility, were designed to suspend electrical cables, wiring, and small-bore piping throughout the facility. Cable trays are also used in biochemical plants, solar power plants, sports stadiums, green energy plants, as well as, traditional plants such as petroleum refineries, chemical and coal-fired power plants. As a general rule, cable trays protect and carry cable and wiring from point “A” to “B” inside the facility.

This section of cable tray in the photograph (blue in color) is 25’ long, 7’ wide, and 11’ tall completely assembled. It is fabricated from carbon steel and painted with a highly chemically resistant epoxy mastic designed for immersion conditions to protect against corrosion in marine or industrial conditions. PT&P can fabricate any combination of instrument stands and structural supports from floor mounts, wall mounts to secondary supports, and more. In addition, we have the capabilities to do what few other structural fabricators can do including:

– Complete Engineering designs including FEA (Ansys) and Structural Engineering (STAAD)

– Load Testing

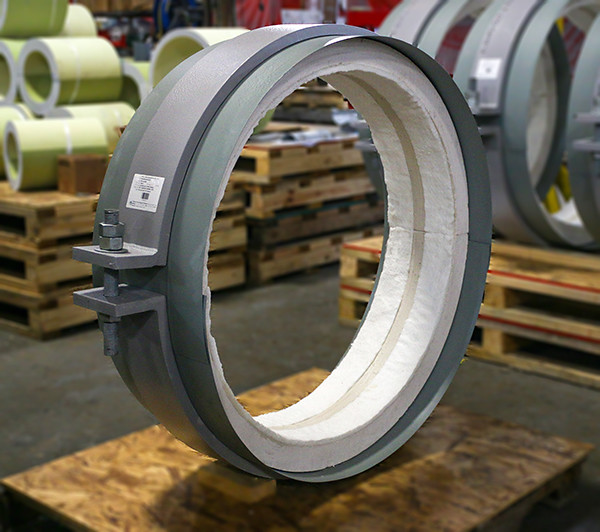

– Incorporation of Contact Corrosion Solutions including TPI (half-round thermoplastic) and FRP

– Incorporation of Vibration Control Solutions

– Ability to fabricate with a wide variety of metals including all grades of Stainless and Nickel Super Alloys

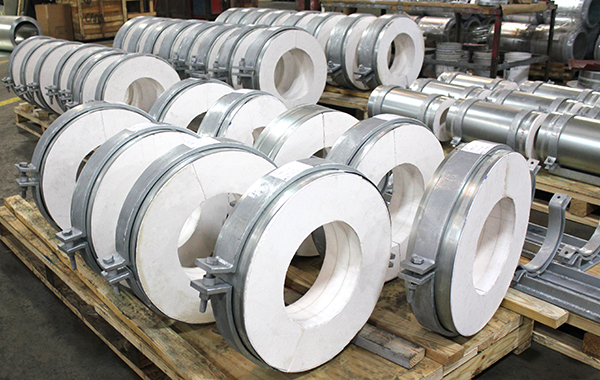

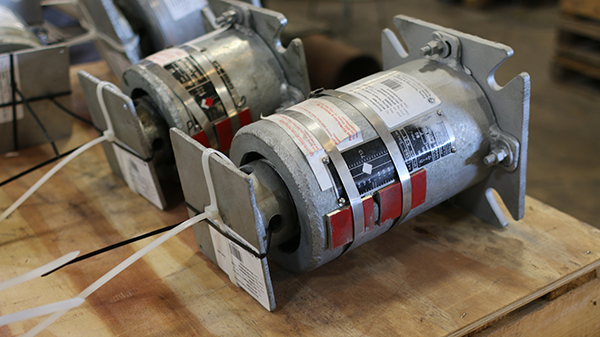

PT&P has worked on and is working on some of the largest water remediation projects in the US where we have supplied expansion joints, variables, fire protection insulated supports, and structural pipe supports. Our ASME shop is large, local to the United States, and includes heavy-duty equipment and specially trained personnel with over 45 years of experience making this division of PT&P ideal for large-scale projects such as this structural support as we can leverage our massive manufacturing scale and expertise.

Read More