|

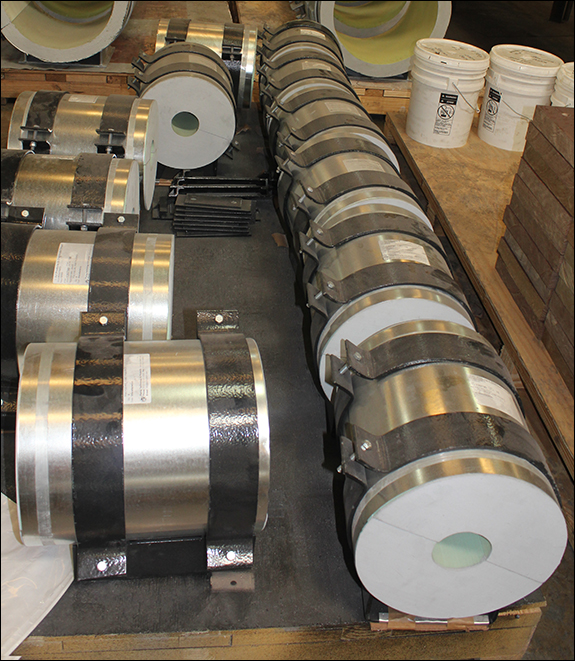

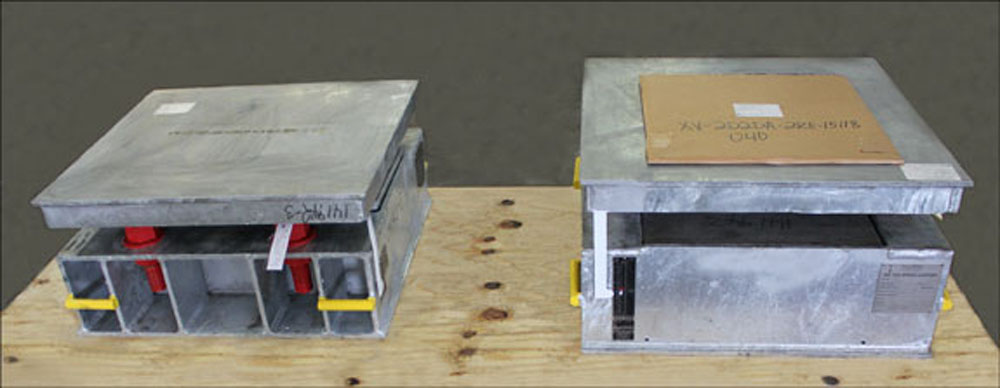

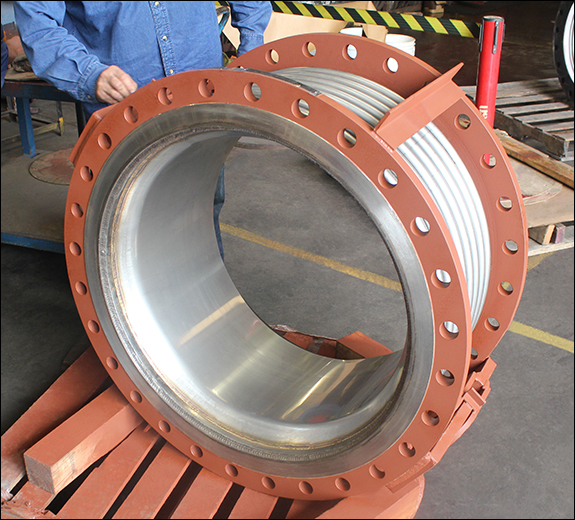

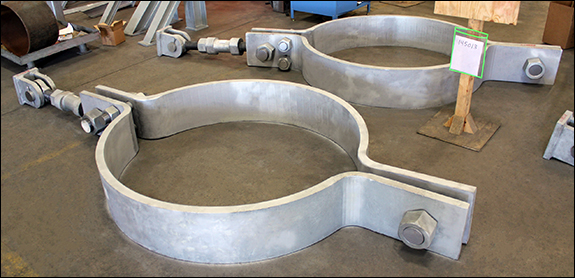

PT&P custom designed pre-insulated pipe supports for a cryogenic pipeline at a petrochemical complex in Louisiana. They range in size from 46″ – 52″ diameter and are designed for temperatures down to -20°F. The top portion of the support is 10 lb. density and the bottom is 20 lb. high density polyurethane foam (PUF) insulation. The shoe and bearing plates were fabricated from carbon steel with a hot-dipped galvanized finish. These cold shoes include a vapor barrier comprised of a three layer lamination of polyester film and aluminum foil. Standard quality control tests were performed prior to shipment.

Read More