Blog

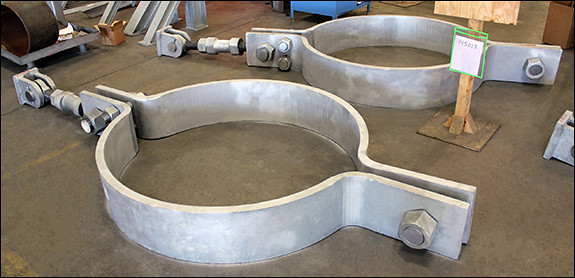

Custom Designed Pipe Clamp and Sway Strut Assemblies for an Ethane Cracker Facility in Texas

| Type: | Pipe Clamp and Sway Strut Assemblies |

| Design: | Operating load: 99,650 lb. | Temperature: 550°F |

| Material: | A36 Carbon Steel |

| Size: | Clamps: 149″ L x 14″ W x 2″ T | Load Bolt: 4-1/2″ | 68″ Dia. Pipe |

Piping Technology & Products custom designed pipe clamp and sway strut assemblies assemblies for an ethane cracker facility in Texas. The clamps are designed for a 68″ diameter pipe using a bar size of 149″ long x 14″ wide x 2″ tall. The load bolt size is 4-1/2″ and the inside bolts, rods, nuts, and turnbuckle are 4″ diameter. The assemblies are completely fabricated from A36 carbon steel, and designed for an operating temperature of 550°F with a load capacity up to 99,650 lb. A visual inspection test with sample pipe and dimensional check were conducted prior to shipment.

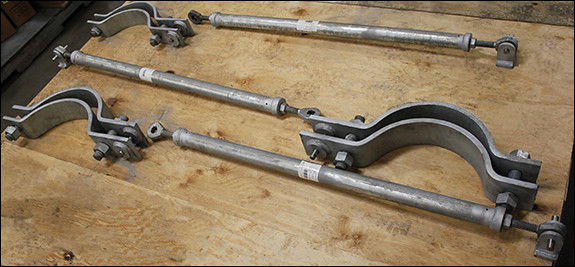

Read MoreSway Strut and Pipe Clamp Assemblies Designed for an Energy Combustibles and Lubricants Facility

Piping Technology & Products designed these Fig.2110F sway struts and pipe clamp assemblies for an energy combustibles and lubricants facility in Argentina. The sway struts are 60″ in length with clamp sizes of 16″ and 12″ diameters. All components were fabricated from A-36 carbon steel. They are designed for an operating load of 4,500 lb. The sway struts are designed to let the pipe sway within a certain radius.

| Type: | Sway Strut and Pipe Clamp Assemblies |

| Design: | 4,500 lbs load |

| Material: | A-36 Carbon Steel |

| Function: | Let the pipe sway within a certain radius |

Work-Life Success at Piping Technology and Products

PT&P Designed Pipe Roller Stands for a Wastewater Treatment Plant

| Type: | Pipe Roller Stands |

| Design: | 1,000 lb. Load | 30″ Dia. Pipe | 18-3/4″ x 13″ x 10-3/16″ BOP |

| Material: | Stainless Steel |

| Function: | For support of piping that expands and contracts longitudinally and where vertical adjustment is not necessary. |

Piping Technology & Products, Inc. designed pipe roller stands fabricated from stainless steel for a wastewater treatment plant. Each roller has two spring housings with eight springs in each. They are designed for an operating load of 1,000 lb. on a 30″ diameter pipeline. The rollers measure 18-3/4″ x 13″ x 10-3/16″ BOP and went through quality control inspection and tests prior to shipment.

Read MoreAdjustable Pipe Stands Designed for a Crude Oil Terminal in Texas

| Type: | Adjustable Pipe Stands / Saddles |

| Design: | 3″ to 25″ Dia. | +/-2″ Adjustment |

| Material: | Carbon Steel with a HDG Finish |

| Function: | Allow adjustment after expansion and contraction |

Piping Technology & Products, Inc. designed and fabricated fifty-seven adjustable pipe stands for a Crude Oil Terminal in Texas. All the supports are fabricated from carbon steel with a hot-dipped galvanized finish. They are designed for 3″ to 25″ diameter pipelines with +/- 2″ of adjustment. Each base plate has been pre-drilled to accept anchor bolts provided at the site. The function of the pipe stand is to allow for adjustment of the support after expansion or contraction of the pipeline.

Read MoreHeavy Duty Pipe Saddles Designed for an Ethane Cracker

| Type: | Heavy Duty Pipe Saddles |

| Design: | 60″ Dia. | 23-5/8″ Length | 5-18″ from BOP |

| Material: | Carbon Steel with a HDG Finish |

| Testing: | Visual | Sample Pipe | Dimensional |

Piping Technology & Products, Inc. designed and manufactured these heavy duty pipe saddles for the Ethylene Plant Project in Texas. The saddles are fabricated from A36 carbon steel with a hot-dipped galvanized finish and designed to support pipes up to 60″ in diameter. They measure 23-5/8″ in length and 5-1/8″ from BOP. Standard Q.C., visual inspection with a sample pipe and dimensional tests were performed prior to shipment.

Read MoreVariable Spring Supports Designed for a Furnace Application in Oklahoma

| Type: | Variable Spring Supports |

| Design: | 1,765 lb. Load | +/- 5% Spring Rate |

| Material: | Carbon Steel with Red Oxide Primer |

| Testing: | Standard Spring Rate & Calibration Tests |

PT&P custom designed variable spring supports for a furnace application at a Nitrogen Facility in Oklahoma. The furnace springs are fabricated from carbon steel and painted with a red-oxide primer to help prevent corrosion. The spring supports are designed to support loads up to 1,765 lb. With a spring rate calibrated to be within +/- 5% of the theoretical value.

Read More