PT&P supplied over 400 clevis hanger assemblies for a pulp and paper plant in Indonesia. The assemblies accommodate elevation differences ranging from 94-1/2″ to 138″ with pipe diameters ranging from 1″ to 24″ and a rod diameter range of 3/8″ to 1-1/4″. All components were fabricated from hot-dipped galvanized carbon steel and are designed for ambient temperatures and loads ranging from 700 lb. to 7500 lb.

Read MoreBlog

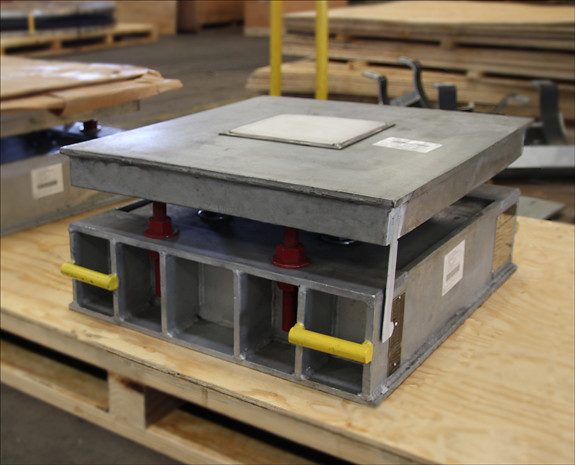

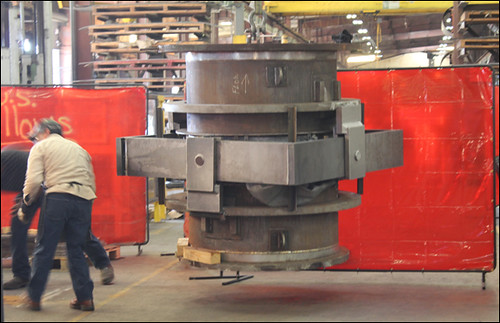

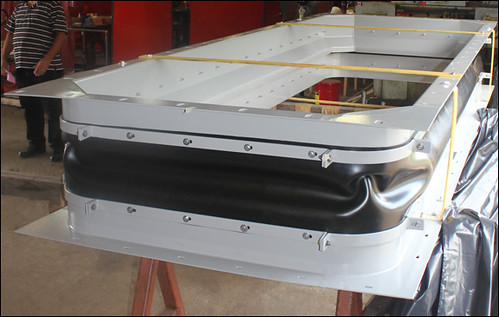

Big Ton Spring Supports Designed to Support a Pressure Vessel

These big ton spring supports were custom designed for an LNG plant in Australia. These units were designed with PTFE, 25% glass filled slide plates, and will be used under the saddle supports of a horizontal pressure vessel. The big tons were selected due to a combination of confined space, heavy loads, and thermal expansion. The units measure 28-3/8″ x 25-3/8″ x 13” and are capable of supporting a load up to 11,488 lb while accommodating a down travel of 0.31 inches.

Read MoreConstant Spring Supports Designed for a Power Plant in New Mexico

PT&P fabricated constant support assemblies for a power plant in New Mexico. The constant assemblies will be used in conjunction with structural supports also provided by PT&P. Operating loads range between 7,000 lb. and 20,000 lb. and designed for movements from 10-1/2″ to 12″. All thread rods were coated with rust prevention compound and the constants were painted with Intergard® 475 HSS. The travel stops are wired to the constants frame and can be reused to lock the constant, preventing travel during plant maintenance or shutdowns. Standard load and travel tests were completed according to MSS standards prior to shipment.

Read MoreSign-up for our next Webinar on Variable Spring Supports

This webinar is over, view the recording in our webinar archives

![]() Variable Spring Support Design, Size Selection, Installation & Maintenance Webinar

Variable Spring Support Design, Size Selection, Installation & Maintenance Webinar

This Webinar will focus on the different types of variable spring supports and big ton variable spring supports. Learn about the special features available, in addition to the design of a variable support. View how the different coil configurations produce a unique response to an applied load and see how a spring assembly is loaded. Discover the basic steps in selecting a hanger design and the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to replace or re-calibrate a variable spring support, as well as adjustments, shutdown and isolation procedures.

Read More

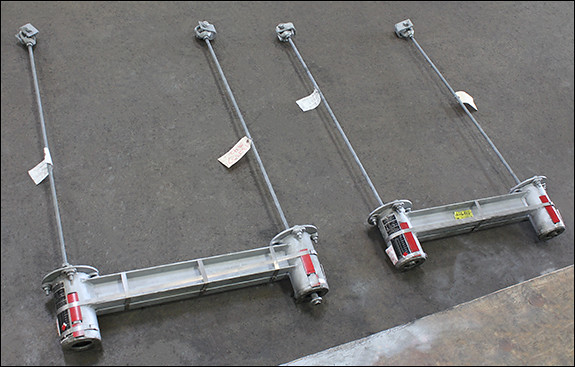

Custom Sway Strut and Pipe Clamp Assemblies for an LNG Plant in Australia

PT&P fabricated and designed 52 of these custom sway strut assemblies for a liquid natural gas plant in Australia. These are manufactured from carbon steel with 304 stainless steel pins. The pipe sizes range from 2”-72” diameter, with a total length ranging from 27” to 137”. The sway struts are fabricated to restrain either tensile or compressive force in one direction while providing for movement due to thermal expansion or contraction in another direction. These sway struts have an operating temperature of 650°F and are designed for operating loads ranging of 650 lb. to 120,000 lb.

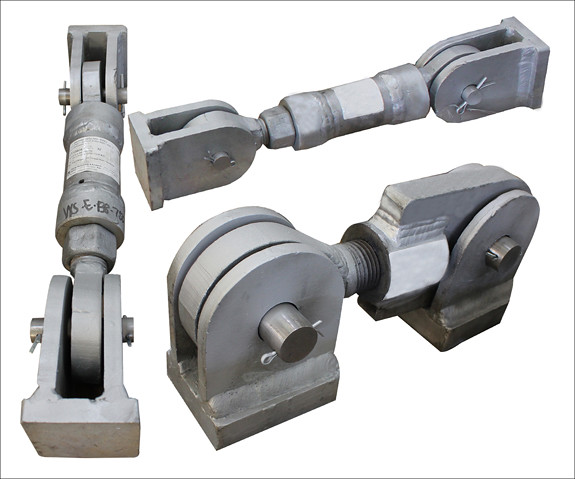

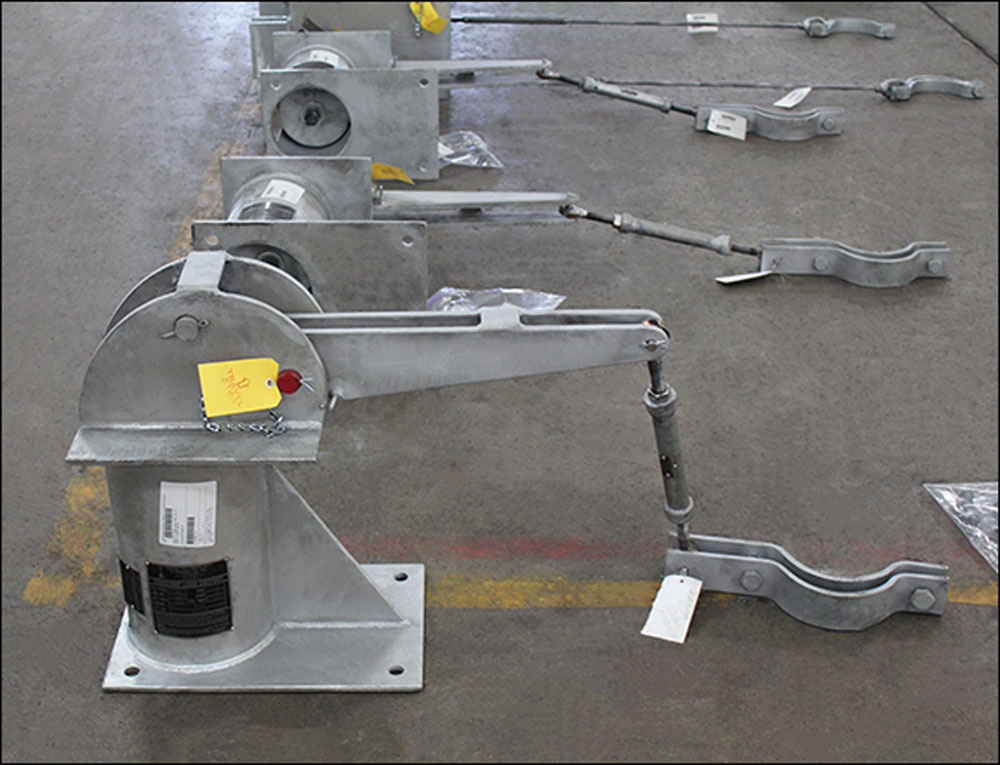

Read MoreSpecial Sway Struts Designed for an LNG Plant in Australia

PT&P custom designed and fabricated 67 mini sway strut assemblies for a liquid natural gas plant in Australia. The sway struts are fabricated from galvanized carbon steel with 304 stainless steel pins. They are 14-7/16” long and capable of a 62,200 lb. load with an operating temperature of 650°F. The sway struts are fabricated to restrain either tensile or compressive force in one direction while providing for movement due to thermal expansion or contraction in another direction.

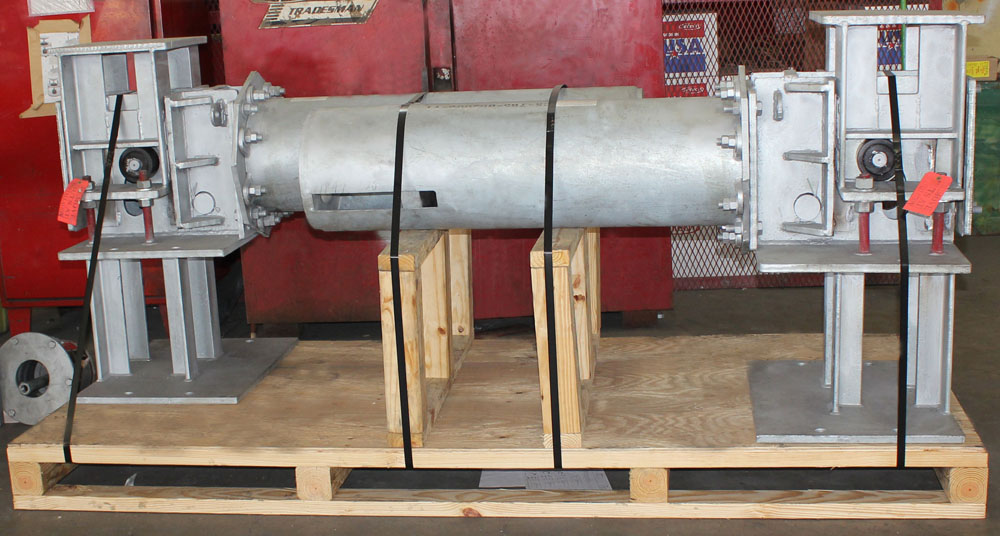

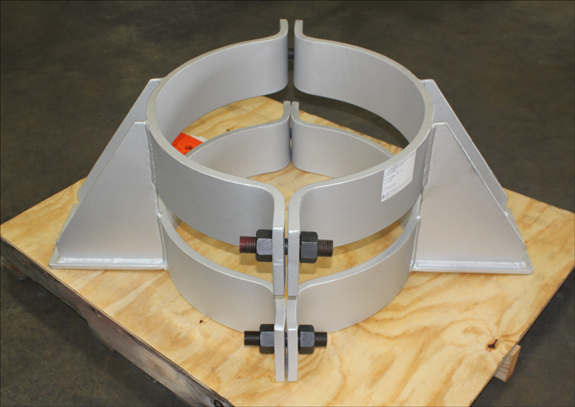

G-Type Variable Springs Support Designed for an LNG Facility

PT&P designed these G-Type variable spring support assemblies for an LNG facility in Saudi Arabia. The variables are comprised of two standard spring housing joined together with an intermediate bridge assembly. They are designed for an upwards travel range of 0.078″ to 0.118″. The variables were fabricated from carbon steel with a hot-dipped galvanized finish. Standard load and travel testing was completed prior to shipment.

Read MoreProduct Highlights from 2015

|

|

|

| 108″ Dia. Storage Tank and Containment Tank | Heavy Duty Yoke U-Bolt Pipe Clamps | F-Type Spring Supports for LNG |

|

|

|

|

|

| 12″ Tied Universal EJ | 46″ Dia. Inline P.B. EJ | 30″ Dia. Single Tied EJ | 84″ Dia. EJ for FCC Unit | 20″ Dia. Double Gimbal Expansion Joint |

|

|

|

| 14′ Long Sway Struts | 54″ Hot Shoes | U-Type Constant Springs |

|

|

|

| 90″ Dia. Duct Work for an Ammonia Plant | 11′ Long Fabric EJfor a Gas Turbine | 16″ Dia. Stainless Steel Single EJ’s |

|

|

|

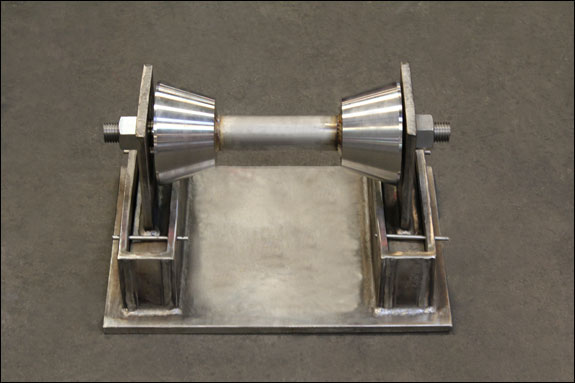

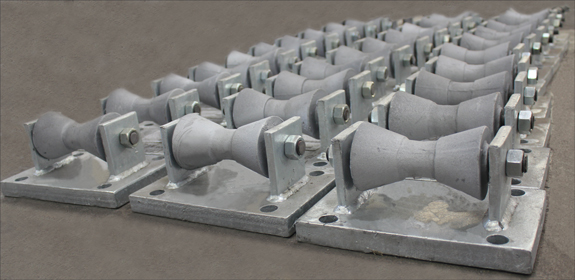

| F-Type Constant Spring Support Assemblies | SS Rollers for a Wastewater Treatment Plant | 24″ Hold-down Clamps w/ PTFE Slide Plates for a Natural Gas Plant |

|

|

|

| 44″ Dia. Fabric EJ’s for a Chemical Plant | Tied Universal EJ for a Nitrogen Plant | 8″ Dia. Tied Universal Expansion Joints |

|

|

| Roller Stands Designed for a 10″ Dia. Pipeline | Sway Struts Custom Designed for a Chemical Plant |

|

|

|

| 136″ Universal EJ for a Thermal Power Plant | 10′ Long EJ for a Nuclear Energy Facility | Stainless Steel Universal EJ’s for a Pipeline |

|

|

|

| Insulated Supports for an Ammonia Project | Pipe Hanger & Clamps for Flue-gas Desulfurization | 16″ Dia. Insulated Supports for High Temperatures |

|

|

|

| 16″ Dia. Tied Universal Expansion Joints | 6″ Single Expansion Joints | 28″ Dia. Gimbal EJ with Floating Rings |

|

|

|

| C-Type Variable Spring Hangers for a Power Plant | 48″ Dia. Cold Shoes for Light Hydrocarbon Production Facility | Compact Spring Supports for a Heat Exchanger |

|

|

|

| 10″ Dia. EJ for HVAC Service | 75″ Long EJ for a Boiler Exhaust Application |

153″ Fabric EJ for a Gas Turbine Facility |

|

|

|

| Variables for a Furnace Application in an Ammonia Plant | 36″ Dia. Cryogenic Pipe Saddles for LNG Service | 42″ Dia. Chrome-Moly Pipe Clamps |

|

|

|

| 32″ Dia. Externally Pres. EJ | G-Type Variables | 20″ Dia. Inline Pressure Balanced EJ’s |

|

|

|

| F-Type Variables for a Chemical Processing Plant | Constants for a Steam Methane Reformer | Pipe Clamp Assembly for Partial Oxidation Unit in Synthetic Gas Plant |

|

|

| Gimbal EJ’s for a Flare Gas and Steam Application | Single EJ’s for a Hydrocarbon Vapor Pump |