We had a great turnout for our U.S. Bellows Expansion Joint In-Depth Webinar on October 24th. We are proud to announce the winner of our drawing for the EJMA Standards Ninth edition is George. Be on the lookout for our next giveaway!

Read MoreBlog

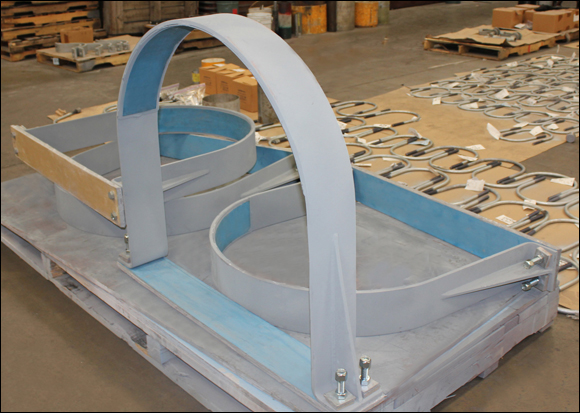

200 E-Type Horizontal Constant Spring Supports for a Fired Heater Radiant Manifold

These 200 E-Type horizontal constant spring supports are fabricated from A-36 carbon steel with a hot-dipped galvanize finish. The pins made for constants operation are A-322-4140 high strength carbon steel. The constants range in size from 22-3/4″ to 26-1/4″ heights, 60″ to 90″ lengths, 18″ width, and 19-1/2″ to 23-1/2″ in coil housing diameters. They are designed for 23,160 lb. to 33,700 lb. loads and 6-1/2″ to 14″ of total travel. A total of sixteen assemblies were custom designed for a fired heater radiant manifold. Each pipe hanger assembly went through standard load and travel testing prior to shipping.

Read MoreVariable Spring Supports with Permanent Upward Travel Stops

Five total assemblies of custom designed variable spring supports were made for an oil refinery in the United Arab Emirates. These springs required a permanent upward travel stop. The spring cans were supplied with PTFE and polished stainless steel slide plates attached to carbon steel load flange. All materials used were domestic (from the U.S.). The springs were tested for lateral loads. The spring coils were stress tested and can withstand temperatures of 176°F (80°C), with a downward movement of 30mm – 45mm.

Read MoreBig Tons with W-Beams as Stilts

Stilts using W-Beams were added to these big ton variable assemblies in order to meet height requirements for an oil refinery in Port Arthur, TX. Entirely fabricated with carbon steel, these big tons measure 50 1/2″ – 70″ L x 18″ – 22″ W by 37″ H and are capable of supporting loads up to 113,734 lb with an upward travel range of .076″ – .816″. Permanent travel stops were later installed in order to prevent any chances of downward shift.

Read More36 Custom Designed Pipe Saddles for a Power Plant

Thirty-six custom designed pipe saddles were created for a power plant in Mississippi. These 20″ W x 72″ L x 30″ H saddles were made with carbon steel with PTFE slide plates. These pipe saddles were designed to support a load of 55,000 lb. and will be applied to fluid bed duct supports.

Read More274 Custom Hot Pipe Shoes Rush Delivered in Three Weeks

We provided a quantity of 274 custom designed hot shoes on an expedited basis to a factory in Arizona. While the normal delivery time on a typical order might be 6-8 weeks, Piping Technology provided these pipe shoes on a 3 week delivery time. The high temperature pipe supports include clamping material fabricated from carbon steel with a red oxide finish, a polyethylene slide base with stainless steel slide plates, high density calcium silicate insulation and an overlapping galvanized sheet metal jacket. The pipe shoes are designed to accommodate 4″-8″ pipes and have an insulation thickness of 2″-3″ and the base measures 11″ to 14″ in width, and 6″ to 15″ in length. The hot shoes are designed for temperatures ranging from 40° F to 600° F. The insulation for these supports is a combination of high density calcium silicate with high strength inserts.

Read More26'-9" Custom Designed Sway Struts with Ball Joints

These 26′-9″ long custom designed sway struts with ball joints were supplied for a power generating facility. There were 4 total assemblies that included 4″ diameter schedule 80 pipe with one ball joint and one extension piece on each end measuring 3″ in diameter and 6″ long. The sway struts, designed to support a load of 29,000 lb., will be used in the facility to allow movement between two structures along a parallel plane.

Read MoreHD-2 and HD-3 Hold-down Pipe Clamps with PTFE Slide Plates

Designed for 20″ to 30″ pipe sizes, these HD-2 and HD-3 hold-down pipe clamps were shipped to a gas pump station in South Dakota. The hold downs were fabricated from carbon steel with PTFE, 25% glass filled liners on the saddle portion and base of the pipe clamp. We fabricated a total of 22 hold down pipe clamps and shipped this rush job within one week.

Read More113 F-Type Variable Spring Cans with PTFE Slide Plates

These F-Type variable spring cans were designed with PTFE, 25% glass filled slide plates for a local oil refinery. Slide plates are used to reduce the friction between the load flange of the spring and the pipe support. This allows for easier adjustment of the spring’s installed height. These variables include external travel stops. The external travel stops are sometimes referred to as universal travel stops and can be utilized to adjust the installed load (also called the cold load) to other installed loads within the working range of the spring. 113 variable springs were supplied for this job. The variables have an installed load ranging from 95 lb. to 11,000 lb. and an operating load ranging from 90 lb. to 10,703 lb. They are part of a plant expansion and will be used to support horizontal piping in an oil refinery.

These F-Type variable spring cans were designed with PTFE, 25% glass filled slide plates for a local oil refinery. Slide plates are used to reduce the friction between the load flange of the spring and the pipe support. This allows for easier adjustment of the spring’s installed height. These variables include external travel stops. The external travel stops are sometimes referred to as universal travel stops and can be utilized to adjust the installed load (also called the cold load) to other installed loads within the working range of the spring. 113 variable springs were supplied for this job. The variables have an installed load ranging from 95 lb. to 11,000 lb. and an operating load ranging from 90 lb. to 10,703 lb. They are part of a plant expansion and will be used to support horizontal piping in an oil refinery.

Read More

Big Ton Variable Spring Supports with Rollers Designed to Support a Load up to 60,000 lb.

These are custom designed big ton variable spring assemblies manufactured for a chemical plant in Brazil. They are fabricated from A-36 carbon steel, with monel rods, nuts and hardware. They measure 18″ L x 26″ H x 26-1/2″ W and are capable of supporting loads up to 60,000 lb. with down travel of .52″. These big tons employ the use of rollers for adequate mobility and are painted to protect against corrosion.

Read More