Sweco Fab., a division of PT&P, fabricated a water treatment vessel from 3/8″ thick SA516 Grade 70 carbon steel for a refining facility in Texas. This pressure vessel has an 84″ outside diameter, is 11′ tangent to tangent and has an overall height of 14′-8″. It is designed for maximum working pressure of 100 psig at 100°F. A radiography test and hydrotest at 130 psig, held for 1 hour was conducted prior to shipment.

Read MoreBlog

New Installation & Maintenance Guide for Pipe Support Hardware

We have added a new Pipe Support Hardware Guide to our Installation and Maintenance section. This guide covers pipe support hardware such as Welded Structural Attachments, Threaded Assembly Components, Clamp Attachments, and more. You can find our corresponding figure numbers, diagrams, and a brief description in each section of the guide.

Read MoreSpecial E-Type Constant Springs Designed to Support Boiler Trim Piping

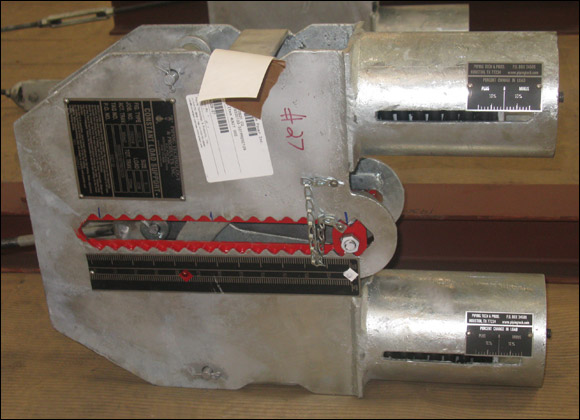

Special PTP-100 E-Type constant spring supports were custom designed to support boiler trim piping for steam generating in an upper thermal power unit. The constants measure 5-3/8″ W x 16-3/4″ L x 23-1/2″ H. They are highly customized to meet the customer’s space requirements and operating method to eliminate the hanger rod from shifting, allowing it to move only vertically while going from cold to hot position. Standard constant assemblies of this size, are about 50% larger and the hanger rod would shift horizontally as the travel reaches the hot position. These constants are designed for loads ranging from 72 lb. to 92 lb. and movements ranging from 10″ to 11-1/2″ downward. Standard load and travel tests were conducted prior to shipment

Read MoreAdjustable Base Supports Designed to Support Trunnions in an Oil Refinery

We designed a total of ninety-four custom adjustable base supports, similar to Fig. 260 adjustable pipe elbow support, to support elbow trunnions in an oil refinery in Indiana. We fabricated these adjustable base supports from carbon steel plates, all-threaded rods, heavy hex nuts and sch. 80 pipes. They will support pipe sizes ranging in size from 1-1/2″ to 12″ in diameter.

Read MoreSolution for Removing Travel Stops in Variable Cans with Heavy Loads

For spring cans capable of 40,000 lb. or greater, we recommend you use jacking bolts to remove the travel stops. Visit our visual media section to learn the Solution for Removing Travel Stops at Heavy Loads.

232 Variable Spring Supports for a Natural Gas Processing and Separation Plant

A total of 232 variable spring supports were custom designed for a natural gas processing and separation plant. This project included various spring sizes from PTP-1 30 C-type to PTP-4 160 F-type assemblies. The variables are fabricated from carbon steel, galvanized and coated with a special 3-coat paint system to protect against corrosive byproducts such as sulphur. The F-types include 304 stainless steel and PTFE, 25% glass filled slide plate assemblies.

Read MoreClamp-On Pipe Shoe Assemblies Were Custom Designed For A Gold Mine Project

These fabricated clamp-on pipe shoe assemblies were custom designed for a gold mine project in the Dominican Republic. They are composed of a clamp-on pipe shoe subassembly combined with a carbon steel pipe extension. A total of nineteen pipe shoes were fabricated for 3″, 4″ and 6″ diameter pipes. The extensions were designed at various heights to position the pipe line at the correct elevation for a sloping line. When a design includes a closed off section, PT&P’s standard is to incorporated vent holes in order to prevent moisture build-up. They are painted with a two-coat paint system to protect against corrosion and include stainless steel tags to easily identify the product code.

Read MorePipe Shoes Designed for Main Steam Piping in a Gold Mine Project

These custom designed pipe shoes were fabricated for main steam piping in a gold mine project. A total of forty-three pipe shoes ranging in size from 20″ to 36″ diameter were designed for temperatures up to 650°F. The shoes ranged in length from 17″ to 24″, width from 20″ to 32″ and height from 3″ to 7″. They are manufactured from carbon steel and have a two-coat paint system to protect against corrosion.

Read MorePipe Clamp Design, Application & Installation Webinar

This Webinar is over… view the recording at www.pipingtech.com/webinar

** Webinar is worth 1 PDH Credit for TX Professional Engineers

Read More

251 Variable Furnace Springs for a Chemical Plant in Virginia

251 variable furnace springs were designed and fabricated for fertilizer production at a chemical plant in Virginia. The furnace cans are carbon steel and painted with red-oxide primer to avoid any potential hazards where exposed to high temperatures. This project included figures: PTP-1-120, PTP-2-150, PTP-2-180, PTP-4-100 and PTP-4-200 variable furnace springs with operating loads ranging from 1,042 lb. to 15,512 lb. A load test on all variable springs was conducted prior to shipment.

251 variable furnace springs were designed and fabricated for fertilizer production at a chemical plant in Virginia. The furnace cans are carbon steel and painted with red-oxide primer to avoid any potential hazards where exposed to high temperatures. This project included figures: PTP-1-120, PTP-2-150, PTP-2-180, PTP-4-100 and PTP-4-200 variable furnace springs with operating loads ranging from 1,042 lb. to 15,512 lb. A load test on all variable springs was conducted prior to shipment.