We are happy to announce that the history section of our website has recently been updated! Four new chapters has been added to the PT&P History. Learn how PT&P got started, what obstacles we had to overcome, and how we are building towards the future. Visit the history section located on our website to read a condensed version of PT&P’s history or you can read our full history by ordering a free copy of Piping Technology & Products History: The First Thirty-Five Years.

Read MoreBlog

Custom Instrument Supports Fabricated from Carbon Steel with a Hot Dipped Galvanize Finish

These custom instrument supports are fabricated from carbon steel with a hot dipped galvanize finish. The supports vary in heights up to 5′ and widths from 18″ to 24″. A total of 126 stands will be used to support instruments at an oil refinery. PT&P offers a complete line of adjustable and welded instrument supports in various mounting styles.

Do you see a need for instrument supports in a current or future project of yours? Get pricing today!

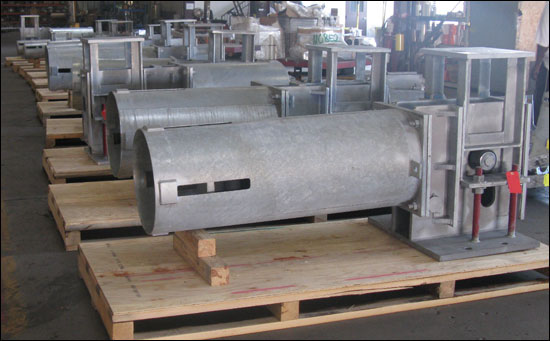

Heavy Duty Yoke U-Bolt Pipe Clamps for a Continuous Catalyst Regeneration Plant

These custom heavy duty Fig. 43 yoke u-bolt pipe clamps are designed for manifold piping in a Continuous Catalyst Regeneration plant in Mexico. The yoke clamps are for a 36″ diameter pipe size and are fabricated from A240 Grade 316 stainless steel. They are designed to support a load of 33,731 lb. and temperatures up to 1100°F. PT&P supplied a total of 16 assemblies, comprised of yoke u-bolt clamps and E-type constant springs, for this project.

Do you need yoke u-bolt clamps or constants? We would be happy to provide you with a quote today.

Large Custom Sway Struts Designed for a Liquid Filters Manufacturer

These custom fig. 2110, size 8 sway struts are for a liquid filters manufacturer located in Mississippi. Both sway struts have a 128,000 lb. load capacity and are fabricated from carbon steel with a hot-dipped galvanized finish. The sway struts measure 68-5/8″ long and have a 4″ diameter rod size. A load test was performed prior to an expedited shipping schedule of 1-1/2 weeks.

Do you require custom supports that are not found in our catalog? No problem! Get pricing today.

Read More

Do you have a plant turnaround coming up?

Do you have a plant turnaround scheduled or planning one in the near future? PT&P is prepared to be there for you throughout the entire process. From planning, to execution, and follow-up, we have what it takes to accomplish a successful plant turnaround.

Prior to Your Turnaround:

– Call our field service team to assist with plant walk-downs to assess your plant for maintenance, repair or replacement of pipe supports and expansion joints

– Contact our quotations department for immediate pricing on pipe supports, expansion joints, or auxiliary steel needed during the turnaround.

– Consult our experienced engineers for guidance on support placement, materials, finishes, etc. to ensure optimum life of the supports.

During Your Turnaround:

– Use our field service team to guide you through installation, start-up, and replacement to safely and efficiently handle your turnaround.

– For quick delivery, PT&P stocks over 1500 bellows, over 100,000 lb. of insulation materials, over 30,000 spring coils, and over 1 million pounds of standard items

Post Turnaround:

– Receive training to monitor the supports, and identify potential failure, in order to prevent unplanned turnarounds in the future.

– Learn correct size and selection of pipe supports and expansion joints per application for any post-turnaround resolutions.

– Call on our field service team to develop a data book of existing pipe supports and expansion joints and their conditions in order to identify potential maintenance issues in upcoming turnarounds.

Examples:

A rectangular metal expansion joint was refurbished on an emergency basis for a local chemical plant. Upon arrival, it was acid washed and dye-penetrant examined for any cracks. View the full Article

U.S. Bellows, Inc. refurbished two pressure balanced elbow expansion joints with a quick turnaround for a power generation plant during outages. They are designed for high pressure turbine crossover piping. The first 54″ outside diameter expansion joint leaked from a crack in the bellows causing an unscheduled outage. View the full article.

This expansion joint was received in the morning and shipped to the customer the very same day. The bellows, liner and cover were replaced and the carbon steel parts were sand blasted, cleaned and painted. A dye-penetrant test and hydro-test to 518 PSIG were performed prior to shipment. View the full article.

This expansion joint was received in the morning, refurbished by adding new bellows and limit rods, and then shipped the very same day. New 321 stainless steel bellows were fabricated and the existing flanges were reused by sandblasting and then painting for corrosion protection. View the full article.

Let us assist you on your next plant turnaround. Our field service team is ready to help!

Read More

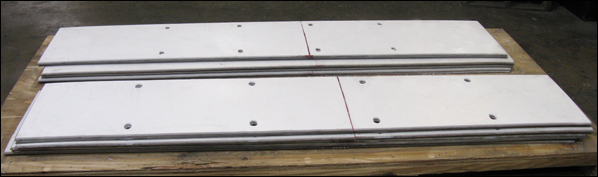

PTFE, 25% Glass Filled Slide Plates Bonded to Stainless Steel Backing Plates

The slide plates are comprised of 1/4″ thick PTFE, 25% glass filled slide plates bonded to 1/8″ A240 grade 316 L stainless steel backing plates. Stainless steel was used for better resistance to corrosion and longevity. The assemblies measure 83″ long by 20″ wide and will be installed underneath a bridge. A total of 16 slide plates were fabricated and designed for a pressure of 500 psi at ambient temperature. PTFE, 25% glass filled material provides a low coefficient of friction, is easy to install, does not require surface treatments, or grouting, and is unaffected by weather conditions.

Read MoreLadders and Pressure Vessel Platforms for a Delayed Coker Unit Stripper Tower in California

The ladders and platforms were designed to be installed on a 90′ tall pressure vessel. The ladders were fabricated from carbon steel and ranged in size from 5′ to 38′ in length. The vessel platforms were also fabricated from carbon steel and measure up to 16′-6″ in diameter.

Do you require ladders or platforms for a vessel or tank? Let us serve your needs today!

Read MoreU-Type Constant Springs Custom Designed for Large Travel for an Oil Refinery

These figure 200 U-type constant springs were fabricated from A-36 carbon steel and range in size from 30-1/2″ to 41″ in height, 25″ to 31″ in width, and 68″ to 80″ in length. These are horizontal constants designed to support piping from below where the base plate is bolted directly to the top of the steel or the foundation using anchor bolts. Loads range from 9,000 lb. to 42,000 lb., and vertical movements range from 6″ to 11″. All the constants went through standard load and travel testing per MSS Standards prior to shipment.

Want to learn more about constant springs? Instantly view a recording of a past webinar.

Read MoreF-type Variable Spring Support with a Stainless Steel Wire Rope Isolator

This F-type variable spring support was customized with a wire rope isolator for a facility located in Canada. The variable spring was designed for a load of 12,000 lb. The wire rope isolator is essentially a 1.25″ diameter stainless steel rope looped eight times between two chemically conversion coated aluminum alloy retaining bars. The wire rope isolator is effective in vibration isolation and energy absorption.

Need a similar support? We’d be happy to serve your needs!

24" Bolted Clamp Pipe Shoe with Slide Plates for a Radiant Syngas Cooler Piping System

These customized bolted clamp pipe shoes with PTFE, 25% glass filled slide plates were fabricated for a radiant syngas cooler piping system in Indiana. The supports were designed for 24″ diameter piping with a pressure of 2,256 psig at 350°F. The axial displacement is +/- 1.326″ facilitated by slide plates on three quadrants. These pipe shoes were custom designed and fabricated entirely from carbon steel with a hot-dipped galvanized finish.

Do you have a requirement for bolted clamp pipe shoes? Let us price it today.