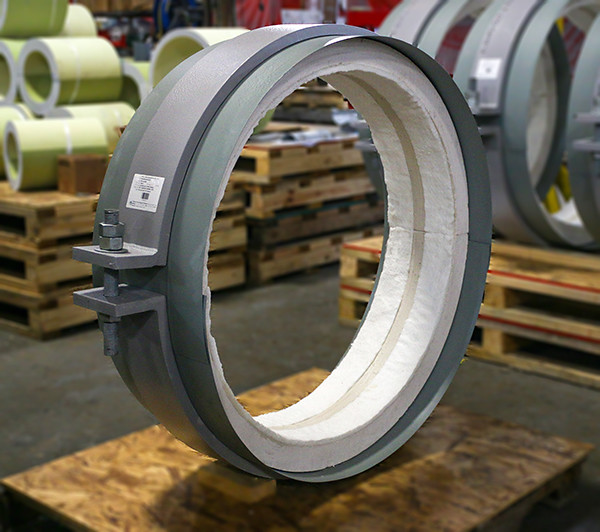

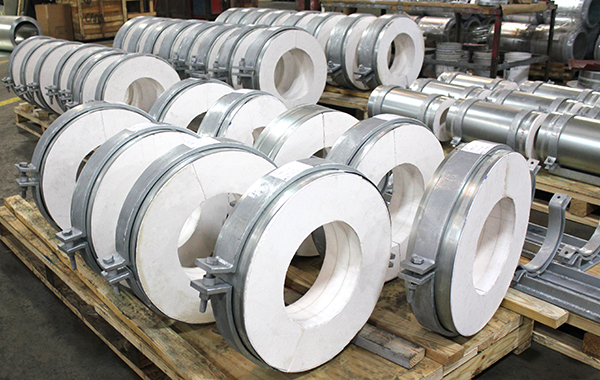

PT&P manufactured 48″ diameter pre-insulated pipe supports for a high-temperature pipeline at a phenol plant in Texas. Phenol is an important aromatic organic compound used in several products like plastics, nylon, epoxies, detergents, mouthwash, antiseptics, and other pharmaceutical drugs. PT&P has consistently supplied products to these types of plants for many years and has done work for most of the largest phenol plants in the world. The production of phenol from petroleum-derived feedstocks can involve temperatures, where large bore piping can reach 250°F. Phenols are used in a diverse range of end markets including construction, automotive, electronics, and fibre industries. Some other plants that utilize large bore piping at high temperatures, are Biofuels, Semiconductor, and Old Sands Extraction processing plants. These hot shoes, in particular, are designed for pipe sizes up to 48″ in diameter. They include 6″ thick by 4″ width calcium silicate insulation, hot-dipped galvanized steel, and are designed for a load of 7,000 lb. Standard quality tests were performed before shipment. At Piping Technology and Products, we can supply a wide range of different types of pipe supports to meet your design specifications. This enables our clients to order from one vendor as opposed to several different vendors to manage the supply chain for project success in the most cost-effective manner while keeping deliveries on time. This order consisted of six different types of supports such as variable assemblies, constant support assemblies, sway struts, and pre-insulated pipe supports along with associated “off the shelf” hardware items. We have served the piping industry for over 45 years providing a unique array of engineering and manufacturing experience to an ever-changing industry.

Read MoreBlog Category: PRE-INSULATED PIPE SUPPORTS

High-Temperature Supports Designed for a Petrochemical Plant

Pipe Shields, Inc., a division of PT&P designed pre-insulated pipe supports for a high-temperature pipeline at a petrochemical plant overseas. This style of insulated support is designed to be compact, easy to install and eliminate the need for field welding. The insulation is 5-1/2″ thick utilizing 18 lb. and 28 lb. pcf high-density calcium silicate. The “hot shoes” are fabricated from carbon steel and hot-dipped galvanized for corrosion protection. They are rated for temperatures from +40°F to +1800°F. Q.C. inspections and dimensional tests were performed before an expedited shipment.

Such insulated supports are used for chilled water, hot water, and steam line applications in industries ranging from pharmaceutical, semiconductor, paper mills, chemical plants, data centers, biofuels, and food processing to name a few. Piping Technology and Products, through its subsidiary, industry leader, and pioneer, Pipe Shields, has supplied to all these markets in the USA and internationally for over 45 years. Most recently, we made a large investment to automate manufacturing in our Houston plant to increase throughput and yield to support our customers’ needs for just-in-time deliveries reducing cash requirements on projects.

View Pipe Shields’ Model D3100 – Insulated 2-Bolt Hanger

Read MoreHigh-Temperature Pre-Insulated Pipe Supports Designed for 42″ Dia. Pipelines

Pre-Insulated pipe supports were designed for high-temperature service at an oil refinery for a client that specializes in the engineering and design of fired heaters, furnaces, pre-heaters, and heat recovery systems. These high-temperature pipe supports were fabricated from carbon steel and designed for pipe sizes ranging in 36” – 42” diameter and are not only used for new construction but also upgrades and revamps. The “hot shoes” were designed with the addition of “Spring Washers” (not shown here) to maintain consistent clamping force when the pipe expands and contracts. The insulation is 3″ thick and comprised of High-density Calcium Silicate (asbestos-free) structural inserts treated with water repellant. Standard quality tests were performed before shipment. Our hot shoes are used extensively in Refineries, Styrene Plants, Hydrogen Plants, LNG Facilities, Semiconductor Fabrication Facilities, and General Building Construction.

Read More6-1/2 Foot Diameter Custom Insulated Sliding Pipe Shoes for HVAC Service at a Semiconductor Manufacturing Facility

| Type: | Insulated Sliding Pipe Shoes |

| Size: | 78″ NPS | 12″ L x 90″ H x 85″ D |

| Material: | HDG Carbon Steel | High-Density Calcium Silicate |

| Design: | +/- 3″ Axial & +/- 1″ Lateral Movements Operating Loads up to 88,000 lb. 200°F Temperature Pipeline |

| Testing: | Q.C. Inspection | Visual & “Fit-Up” Tests |

PT&P custom designed insulated sliding pipe shoes for HVAC service at a semiconductor manufacturing facility. The shoes are fabricated from A36 carbon steel and hot-dipped galvanized for corrosion resistance, and include insulating material consisting of high-density calcium silicate. The insulated sliding shoes are designed for a 78″ pipe size with overall dimensions of 12” L x 90” H x 85” D to accommodate +/- 3″ axial and +/- 1 lateral movement at a pipeline temperature of 200°F. This design can accommodate operating loads of 88,000 lb. with each shoe weighing approximately 1,200 lb. Our quality control department performed visual and “fit-up” tests for this “Rush” shipment. *image shows product during assembly

Read MoreCold Insulated Supports at a Chemical Plant in Texas

| Type: | Pre-Insulated Pipe Supports | Cold-Temperature |

| Size: | 1/2″ -3″ Pipe Sizes | 4″ Thick Insulation |

| Material: | Polyurethane Insulation | HDG CS Jackets |

| Testing: | Q.C. Inspection & Tests |

Pipe Shields, a division of PT&P, custom-designed multiple A6000U series insulated supports for a chemical plant in Texas for cold temperature piping. The cold pre-insulated shoes are fabricated from carbon steel with galvanized jackets, polyurethane foam insulation (PUF) and a vapor barrier. They are designed for pipe sizes ranging from 1/2” to 3” with insulation up to 4” thick. Standard quality control tests were performed prior to shipment. Learn more about our pre-insulated supports and place your order with us today!

Read MoreHigh Temperature Pre-Insulated Sliding Pipe Shoes

| Type: | Pre-Insulated Sliding Pipe Shoe | High-Temperatures |

| Size: | 15″ Long | 4″ B.O.P. | 1-1/2″ – 3″ Dia. |

| Material: | Firetemp® Insulation | HDG CS | SS on Polyethylene |

| Testing: | Q.C. Inspection & Tests |

PT&P custom designed pre-insulated sliding pipe shoes with FRP lining for high-temperature pipelines in Ohio. The “hot shoes” are 15” long, range in diameter from 1-1/2” to 3” and are designed for a B.O.P. of 4”. The shoes are designed with Firetemp® insulation for temperatures up to 1800°F. The supports are fabricated from carbon steel with a hot-dipped galvanized finish and include stainless on polyethylene slide plates. A visual inspection was performed prior to shipping.

Read MoreCryogenic Pipe Supports Designed for an Ammonia Plant

| Type: | Cryogenic Pipe Supports |

| Size: | 14” L x 4″ W x 6″ H | 2″ Dia. | 2″ Thick Insulation |

| Material: | Polyurethane & Foam Glass | Galvanized Steel |

| Testing: | Q.C. Inspection & Tests |

PT&P manufactured multiple pre-insulated pipe supports for cryogenic temperatures in an ammonia plant in Louisiana. These cryogenic pipe supports, also known as “cold shoes” are designed with 2” thick polyurethane and foam glass for insulation and fabricated from galvanized steel for the shoe, with alloy bolts and nuts. They are 2” diameter 14″ L X 4″ W X 6″ H. These insulated supports are designed for insulating and supporting temperatures down to -300°F with a PSI of 200 to 800. Q.C. inspection and tests were performed prior to shipment.

Read More300+ Cryogenic Insulated Pipe Supports (Cold Shoes) for LNG Service

| Type: | Cryogenic Insulated Supports |

| Size: | Range: 6″ to 24″ Dia. Pipe |

| Material: | Carbon Steel | Hot-dipped Galvanized | PUF |

| Design: | 15,000 – 30,000 lb. Load | -112 F | +/- 2″ Movement |

Over 300 pre-insulated pipe supports were custom fabricated for a cryogenic pipeline at an LNG facility in Louisiana. High density polyurethane foam was used for insulation, with thicknesses ranging from 2” to 4”. The cold shoes are for pipe diameters ranging from 6” to 24” and are fabricated from carbon steel with a hot-dipped galvanized finish. They are designed for temperatures down to -112°F, movements of +/-2” and operating loads ranging from 15,000 to 30,000 lb. Standard quality control tests were performed prior to shipment.

Read MoreMicarta Block Assemblies Designed for a Vessel Application

| Type: | Insulated Support – Micarta® Block Assembly |

| Size: | 2″ H x 12″ W x 81″ L |

| Material: | Micarta® | PTFE, 25% Glass-filled |

| Design: | -454°F | Visual / Dimensional Tests |

PT&P designed Micarta® block assemblies for placement beneath the saddle support of a vessel at an oil refinery in Texas. These insulated supports measure 2” x 12” x 81” and include PTFE, 25% glass-filled material bonded to the top of the Micarta®. Micarta® consists of glass fabric with an epoxy resin, which provides great insulating characteristics and superior physical properties. The blocks are designed to prevent cryogenic temperatures down to -454°F from transferring past the base of the support to the supporting steel or foundation. Visual and dimensional tests were performed prior to shipment.

Read MoreOver 100 Cryogenic Pipe Supports Designed for a Nitrogen Facility in Colorado

| Type: | Pre-insulated Pipe Supports “Cold Shoes” |

| Material: | CS | Red Oxide Primer | PUF Insulation |

| Size Range: | 1/2″ – 6″ Thick Insulation | 1″ – 18″ Dia. |

| Design: | -300°F Temperature | Lateral Restraints / Guides |

PT&P custom designed more than one-hundred cryogenic pipe supports for a nitrogen facility in Colorado. The cold shoes are designed for pipe sizes ranging from 1″ to 18” diameter. They are designed with polyurethane insulation ranging from ½” to 5” thick. The clamps are carbon steel and coated with a red oxide finish. The cold shoes are designed as lateral restraints/guides that can support loads in two directions. Standard quality control tests were performed with a 6-8 week turn-around time.

Read More