These custom designed sway braces and variable spring assemblies were designed for hanger duct work in an aerospace development facility. The assemblies measure 67-1/2″ long with a 14-1/8″ O.D. The variables are a modified F-type spring with a pivoting base and non-standard coil combination, including a nested spring design. The assemblies include fully adjustable travel stops and custom end brackets. They are fabricated from carbon steel and designed for load ranges between 1100 lb. and 9250 lb. with a spring rate of +/- 2.78″.

Read MoreBlog Category: SHOCK CONTROL, RESTRAINT & SUPPORT DEVICES

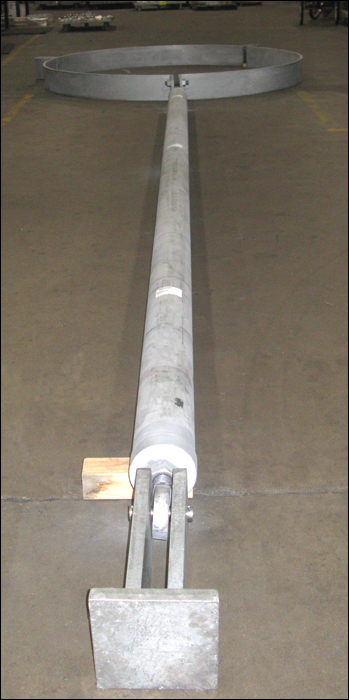

26'-9" Custom Designed Sway Struts with Ball Joints

These 26′-9″ long custom designed sway struts with ball joints were supplied for a power generating facility. There were 4 total assemblies that included 4″ diameter schedule 80 pipe with one ball joint and one extension piece on each end measuring 3″ in diameter and 6″ long. The sway struts, designed to support a load of 29,000 lb., will be used in the facility to allow movement between two structures along a parallel plane.

Read MoreHydraulic Snubbers Designed for a Geothermal Facility

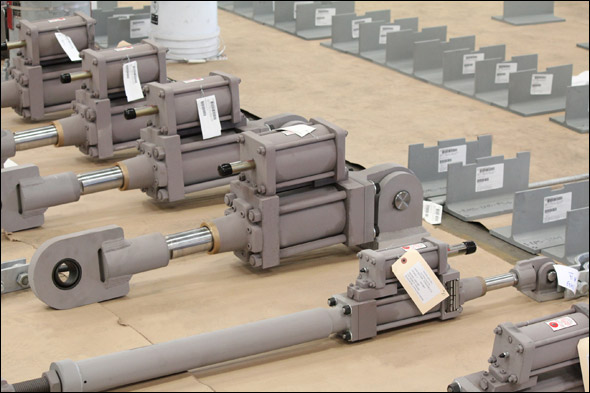

Fronek Anchor/Darling Enterprises, a division of PT&P designed and fabricated hydraulic snubbers for a geothermal facility in California. The Fig. 510 AD snubbers ranged in size from 34-3/4″ to 37-5/8″ piston-to-piston and were designed for a 50,000 lb. maximum load, 5″ cylinder size and a 6″ stroke. The Fig. 511 AD snubbers ranged in size from 56-15/16″ to 59-5/16″ P-P and were designed for a 20,000 lb. maximum load, 2-1/2″ cylinder size and a 6″ stroke. Hydraulic snubbers are designed to protect the piping system when a sudden, heavy load is applied (such as an earthquake of high intensity), which can cause serious vibrations leading to complete destruction. A custom three-bolt pipe clamp fabricated from carbon steel was designed to fit in a limited space. A cycle test throughout the full stroke from zero to fully extended was performed prior to shipment.

Read More7 Ways to Extend the Lifespan of a Hydraulic Snubber

Follow these 7 steps below to maintain and extend the life span of your hydraulic snubber.

1. Observe the fluid level to make sure there is sufficient fluid for the snubber to operate

2. Check for leaks – If the fluid level is decreasing, determine the cause and effect remedial action.

3. Check the condition of the load pins and spherical ball bushings. Apply a high pressure grease for long-term benefits.

4. Check the condition of the exposed portion of the piston rod. Check for scoring, paint or other physical damage.

5. Check the condition of the piston rod wiper. Verify that it’s in position and working effectively.

6. Check for evidence of abuse like welding arc strikes, bent or dented parts, scratched paint, etc.

7. Finally, check the overall physical appearance. This encompasses all of the above.

Read More

Large Custom Sway Struts Designed for a Liquid Filters Manufacturer

These custom fig. 2110, size 8 sway struts are for a liquid filters manufacturer located in Mississippi. Both sway struts have a 128,000 lb. load capacity and are fabricated from carbon steel with a hot-dipped galvanized finish. The sway struts measure 68-5/8″ long and have a 4″ diameter rod size. A load test was performed prior to an expedited shipping schedule of 1-1/2 weeks.

Do you require custom supports that are not found in our catalog? No problem! Get pricing today.

Read More

114" Diameter, 3-Piece Pipe Clamp and Sway Strut Assembly

The 114″ diameter, 3-piece pipe clamp is fabricated from A36 carbon steel and the pins are stainless steel. The sway strut is also fabricated from carbon steel and measures 24′-8″ long. This assembly can support loads up to 27,200 lb. and will be used in an oil refinery in Louisianna.

Do you require clamps or sway struts for an upcoming project? We’d be happy to serve your needs!

Mechanical Snubber Assemblies Custom Designed for an Oil Refinery in California

This week’s feature is on mechanical snubber assemblies custom designed for an oil refinery in California. This project included twenty mechanical snubber assemblies with load ratings from 16,000 lb. to 40,000 lb. and lengths ranging from 65-1/2″ to 103-1/2″. Some of the snubbers were designed to double the standard stroke (up to 12″) by using two MSA-10 sized snubbers back-to-back. All the assemblies were custom designed by adding a carbon steel pipe extension piece. Load tests were performed and the assemblies were shipped in just under four weeks.

Want to learn more about snubbers? Instantly view a recording of a past snubber webinar.

Read MoreHydraulic Snubber vs. Mechanical Snubber

Have you ever wondered which type of snubber to select for your piping system? Should you pick a hydraulic snubber or should you pick a mechanical snubber? Which one is right for your application? This seems to be a common concern for quite a few of our customers, so we have just recently published an article that discusses the pros and cons for both hydraulic and mechanical snubbers. Check out the article, Suitability of Snubbers for Various Applications.

Do you require snubbers for a current or upcoming project? Get pricing today!

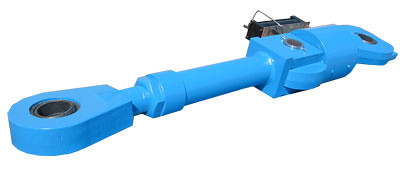

Read MoreHydraulic Snubbers (Fig. 511 AD) with Protective Boots Designed for a Hydro-sulfuric Acid Environment in a Geothermal Power Plant

Fronek Anchor/Darling, a division of PT&P, designed and manufactured hydraulic snubbers with protective boots for a hydro-sulfuric acid environment in a geothermal power plant. They measure 53-5/8″ pin-to-pin with a 3-1/4″ cylinder bore size and 6″ stroke.

The snubbers are designed for an actual load of 15,400 lb., but have a rated load capacity of 20,000 lb. They are fabricated from carbon and alloy steel, and include two coats of epoxy-based paint. An activation velocity test was performed, along with a release rate and drag characteristics test.

Need further assistance selecting your snubber?

> contact our team of engineers

> submit a request for quote

> view more information on Snubbers

Snubbers: A General Overview

We recently posted a new Snubber article on our website. It provides a technical look into both hydraulic and mechanical snubbers – how they are used in a piping system and how they function. Most importantly, the article tells you the difference between various types of snubbers which is helpful in choosing the appropriate snubber for your piping system needs.

Want to learn more about snubbers? Watch a recording of a past snubbers webinar now!