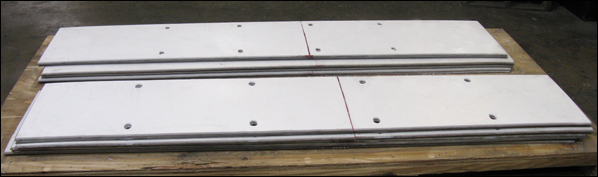

The slide plates are comprised of 1/4″ thick PTFE, 25% glass filled slide plates bonded to 1/8″ A240 grade 316 L stainless steel backing plates. Stainless steel was used for better resistance to corrosion and longevity. The assemblies measure 83″ long by 20″ wide and will be installed underneath a bridge. A total of 16 slide plates were fabricated and designed for a pressure of 500 psi at ambient temperature. PTFE, 25% glass filled material provides a low coefficient of friction, is easy to install, does not require surface treatments, or grouting, and is unaffected by weather conditions.

Read MoreBlog Category: SLIDE PLATES

Custom Designed Variable Spring Supports with Stainless Steel Slide Plates

This custom designed variable spring assembly is comprised of a standard PTP-1-160 type F variable spring with a supplementary extension and load flange with a stainless steel slide plate. The variable is fabricated entirely from carbon steel with a hot-dipped galvanize finish. The extension is schedule 40 pipe, 8″ in diameter and 12-5/16″ in height. The slide plate is fabricated from A240 grade stainless steel and is welded to the top of the load flange. This support will be used underneath a 16″ diameter pipe with a dummy leg. It is designed for 1/16″ vertical travel and 1/8″ horizontal travel for an oil refinery in Algeria.

Do you require custom variables or slide plates for your piping system? Get pricing today!

19 Sets of Phosphorus Bronze and Stainless Steel Slide Plate Assemblies for Supporting Vessels

The slide plate assemblies are fabricated from stainless steel, phosphorus bronze, and carbon steel. The 2″ thick carbon steel base plate is securely anchored to a concrete foundation, and the stainless steel slide plates are affixed to the base plate by countersunk attachment bolts. The phosphorus bronze slide plates, with machined grooves on the underside are placed on top of the stainless steel plates.

|

|

To allow for lubrication between to the contact surfaces of the two slide plates, grease is added through a fitting on the side of the bronze slide plate. The fitting allows access to a channel in the center of the bronze slide plate that leads to the grooves. A hole is located in the 2″ thick base plate to allow for grout to be poured through after installation.

Want to learn more about slide plates? View a recording of a past slide plate webinar!

Slide Plate Assemblies with Marinite® Insulation and Vibration Pads

The slide plate assemblies were fabricated from a combination of stainless steel for the low-friction sliding surface and 2-3/4″ Marinite® insulation to isolate the higher temperatures. A fabric reinforced isolator pad was placed between the slide plate and the I-beam for vibration control. The slide plates were tested for both load and heat transfer and will be utilized in a chemical plant.

Do you need slide plates for your application? Let us price them for you today!

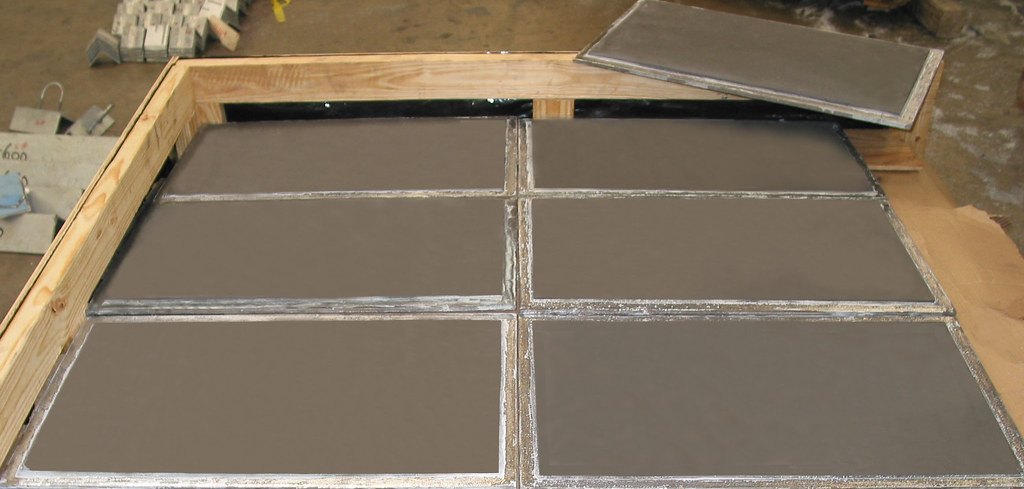

PTFE, 25% Glass Filled, Slide Plates for a LNG Plant in Trinidad

Piping Technology & Products, Inc. designed and manufactured PTFE, 25% glass filled, slide plates for cable trays located on a floating structure. The slide plates are used to reduce the friction between the cable trays and the structural steel it is resting on. These particular slide plates are bonded to stainless steel backing plates that are bolted to the structure.

Want to learn more about slide plates? Instantly view a slide plate webinar today!

Bronzphite® Slide Plates for an Oil Refinery in Texas

The Bronzphite® slide plates shown above are constructed from graphite and phosphorus bronze with dimensions ranging from 3″ x 3″ to 6″ x 36″. They are designed for up to 500ºF and a total travel of up to 30″.

In general, Bronzphite® is a self-lubricating bearing plate made of a high quality bronze with graphite filled grooves. The solid graphite inserts are arranged in various patterns and sizes to meet customer specifications. This type of slide plate is best suited for high loads, low velocity applications and in places where the use of oil or grease in undesirable or unfeasible.

Want to learn more about slide plates? View a past slide plate webinar now!

13,900 lb. Load Pipe Shoes and Bronzphite® Slide Plate

Piping Technology and Products, Inc. recently designed and fabricated more than 75 pipe shoe and Bronzphite® slide plate assemblies for an oil refinery in Texas. Each assembly consists of two pipe clamps, a base plate and a maintenance free Bronzphite® slide plate. The pipe shoes with sizes ranging from 18 to 24 are fabricated from A387 alloy steel. They are designed for 965°F and 2 of horizontal movement.

The 3 x 3 Bronzphite® (graphite impregnated bronze) slide plates are self-lubricating bearing plates made of a high quality bronze with graphite filled grooves. They are designed for heavy loads, low velocity applications, and for situations where the use of oil or grease is undesirable or unfeasible.

Do you require pipe shoes or slide plates in your piping system? Let us price them for you today!

61" x 61" Graphite Slide Plates for a Refinery Project in India

PT&P designed and fabricated eighteen graphite slide plates for a refinery project in India. These plates are made of graphite sheets with thicknesses of 6mm and 12mm. The overall dimensions of the plates are 3/8″ x 19-11/16″ x 19-11/16″ and 3/8″ x 61″ x 61″. The plates will be tack welded on top of big ton spring supports in the refinery to minimize frictional effects.

Do you see a need for slide plates in your piping system? Let us price them for you today!

Read MoreBronzphite® Plates for a Construction Company in Dubai

These ½ x 7 x 12 Bronzphite® plates were bolted to a 2 ¾ x 11 x 16 backing plate with a 5mm recess. The recess allowed the Bronzphite® plates to be countersunk and bolted to the backing plates. The Bronzphite® plates were designed to withstand 14Mpa working compression and a maximum temperature of 230˚F.

Do you have a need for slide plates in your piping system? Let us price them for you today!

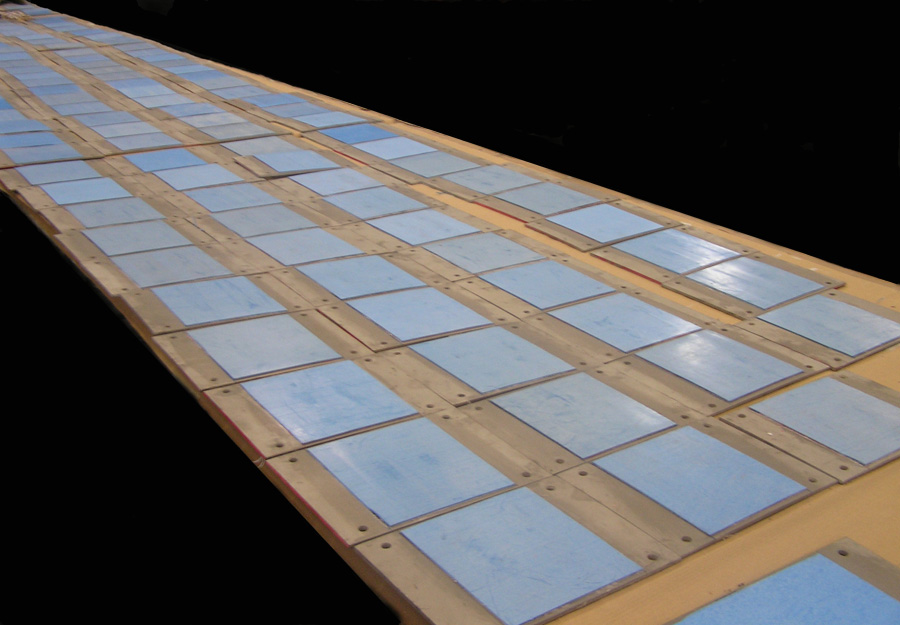

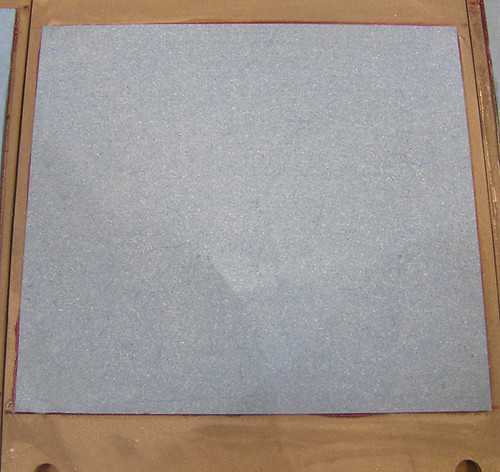

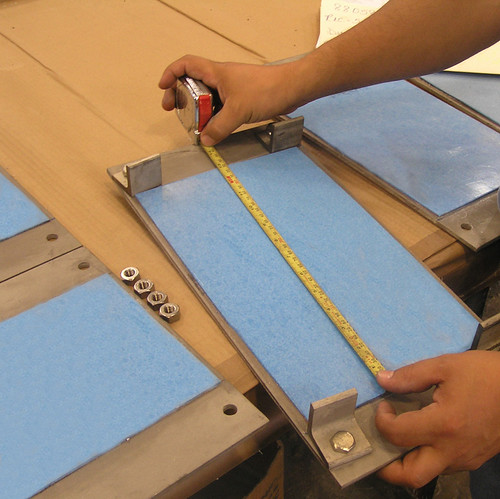

PTFE, 25% Glass Filled, Slide Plates for a Chemical Plant in Texas

Piping Technology & Products, Inc. designed and manufactured PTFE, 25% glass filled, slide plates for a chemical plant in Port Arthur, Texas.

These slide plates are constructed of PTFE, 25% glass filled, bonded to stainless steel backing plates. The top plates range from 123 ¾ square inches to 481 ¾ square inches and the bottom plates range from 69 square inches to 616 square inches.

Want to find out more information about slide plates? Visit our webinar archives today!

Read More