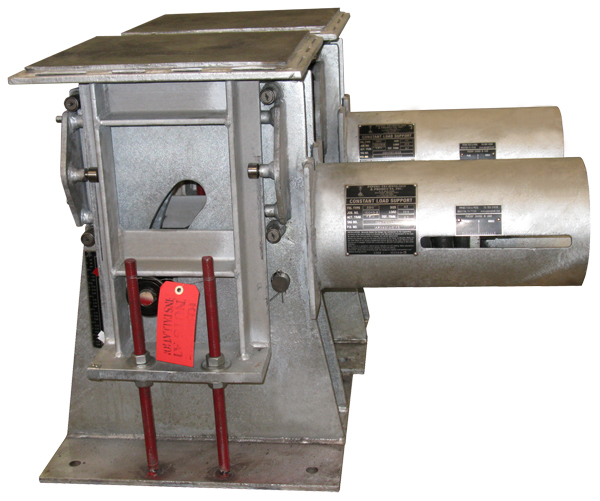

This constant utilizes sealed cam follower roller bearings in place of slide plates that are generally used between the moving table and stationary frame. The rollers help to reduce the friction on the table, reduce residual loads which improve constant deviation, and help to restrict table movement in horizontal directions. These U-Type constants are fabricated from A36 carbon steel with dimensions of 28″H x 37″L x 17″W. The boxing, bolting patterns and loading table location are custom designed per customer specifications. The design also includes a graphite plate bonded to the top of the load flange to reduce the friction between the constant load flange and the saddle support above it. The supports are designed to carry 3015 lb. of piping load with an upward travel of 6″. The constants underwent standard load and travel testing before being shipped to an energy plant.

Want to learn more about constant springs? Instantly view an archived constant webinar!