By David Smith

December 17, 2010

In many chemical plants, refineries  and LNG facilities, there are processes where the “product” inside the piping is at very cold temperatures (down to -320 degrees F in some processes). In these applications, there exists the need to both support and insulate the pipeline while simultaneously allowing and/or limiting movement. The ability to adequately insulate the pipeline helps to increase the efficiency of the piping system by not allowing the “cold” inside the pipe to escape to the environment. However, at points where both supporting and insulating the pipeline is necessary, a special solution is required. Today, several terms have evolved to classify this type of support, including “Insulated Support”, “Cryogenic Support”, and “Cold Support”. Regardless of the term used to describe insulated supports, they all have the same function: to both support and insulate the piping.

and LNG facilities, there are processes where the “product” inside the piping is at very cold temperatures (down to -320 degrees F in some processes). In these applications, there exists the need to both support and insulate the pipeline while simultaneously allowing and/or limiting movement. The ability to adequately insulate the pipeline helps to increase the efficiency of the piping system by not allowing the “cold” inside the pipe to escape to the environment. However, at points where both supporting and insulating the pipeline is necessary, a special solution is required. Today, several terms have evolved to classify this type of support, including “Insulated Support”, “Cryogenic Support”, and “Cold Support”. Regardless of the term used to describe insulated supports, they all have the same function: to both support and insulate the piping.

It is still common to see one of the earliest methods used to support cold pipelines in plants today. These first types of cold supports utilized wood, usually oak as the preferred insulation. The oak would be cut to match the curvature of the pipe and be placed beneath the pipe. A steel cradle or other type of support component could then be placed beneath the insulation wood. Although this method was very crude, it served the purpose of insulating the pipe from the “steel pipe rack.”

Later, in order to prevent the decay of the wood, various coatings were applied. One method to protect the wood still in use today is “impregnation” of the wood using various types of resins or plastics. The result of this method yields a wood that is reinforced with plastic which helps to provide resistance to moisture while still maintaining the insulating properties of the wood. These “laminated wood blocks” also provide higher compressive strength (30,000 PSI) and higher tensile strength (15,000 PSI) than using untreated wood.

|

|

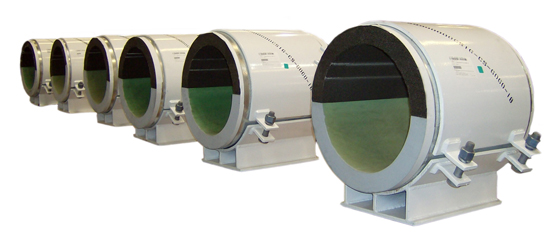

Insulated Pipe Supports with Permali Wood Bases

|

Developments made, during the 1950’s and 1960’s, ushered in the use of chemical compounds to replace previously used natural compounds. “Foam Glass” emerged as an excellent, inexpensive insulator for use on cold pipelines. “Foam Glass” is a lightweight material having a closed-cell structure and is manufactured primarily from recycled glass. It is generally formed in molds that are packed with a mixture of crushed glass and a chemical agent containing carbon. To form the material, heat is applied and the glass grains become soft. The carbon gives off a “gas” that is entrapped in the glass and forms the closed-cell structure. Because it is a great insulator, however, it can be utilized in those portions of the insulated support that are not supporting the load. Because the compressive strength of “Foam Glass” is very low (400 PSI), it is not used in load bearing applications.

Another chemical compound developed during this same time period is Polyurethane. Although not as good an insulator as Foam Glass, polyurethane does provide greater load carrying capabilities due to its higher range of densities. Polyurethane is formed through a “step-growth polymerization” process by involving 1.) a monomer containing at least two isocyanate functional groups with 2.) a second monomer containing at lease two hydroxyl groups in the presence of a catalyst and 3.) a catalyst agent manufactured to be resilient, flexible and durable. Polyurethane is widely used in pipe supports within LNG plants. By varying the densities, polyurethane can be used at different locations to insulate the piping while acting as a vertical, lateral or anchor support. When a protective coating is applied (such as monolar mastic), the material becomes highly resilient to moisture. Additionally, when combined with other additives, polyurethane offers excellent flame-retardant characteristics. Utilized between the steel pipe support components and the pipeline, polyurethane can support the piping in a number of ways. Most applications incorporate multiple 180-degree sections of polyurethane surrounding the pipe with varying lengths, dependent upon the load or weight of the pipe.

|

|

Insulated Supports Designed with a Combination of Polyurethane Foam and Foam Glass

|

Many of the advancements in the insulated pipe support industry are a direct result of technological advancements and continually changing industrial needs. In the future, it is expected that this same type of collaboration will contribute to further improvements of insulated pipe supports.