Most hydraulic snubbers have a piston which is relatively unconstrained in motion at low displacement rates. At high displacement rates the piston “locks up”, that is, the force required to move the piston increases substantially, usually as a result of the closing of a valve.

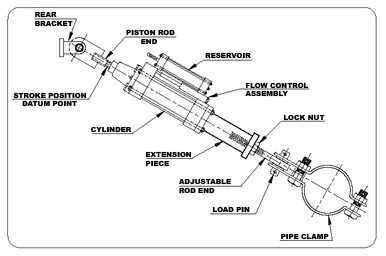

Some of the features include:

• External pressurized hydraulic reservoir for positioning flexibility in any spatial orientation.

• Allows free thermal movement of piping under normal operations.

• Restrains shock loading, both in tension and compression.

• System’s movement is controlled by a flow control device.

Standard Sizes of PT&P Hydraulic Snubbers

| Bore (in.) | Rod Diameter (in.) | Max Recom. Loads (lb.) |

| 1.5 | 1 | 3000 |

| 2.5 | 1.75 | 10000 |

| 3.25 | 2 | 20000 |

| 4 | 2.5 | 30000 |

| 5 | 2 | 50000 |

| 6 | 2.5 | 70000 |

| 8 | 3.5 | 130000 |

PT&P offers seven sizes with cylinder bores of 1 1/2 to 8 inches. These units have a normal load range of 3,000 lbs to 130,000 lbs. All are made to include reservoirs in 6, 12, or 18 inch strokes. Snubbers, as they are sometime referred to, are available with remote reservoirs.

Application

For use on piping systems or equipment when restrained thermal movement must be allowed, but which must be restrained during impulsive or cyclic disturbance. The unit is not effective against low amplitude, high frequency movement. Preferred usage, with standard settings, to prevent destructive results due to earthquakes, flow transients, or wind load. Special settings are available to absorb the continuous thrust resulting from safety valve blow-off or pipe rupture. For the most effective operation of the unit, please specify the mounting position, vertical or horizontal.

Ordering

Please specify figure no., cylinder size, stroke, load, cold, and hot pistons settings, and piston end option. If clamp is required, please specify nominal pipe size, or special O.D. and clamp material. Specification or description of any additional optional features or special settings is required.

Dimensions

| Cylinder Size | Stroke (in.) | A | B Min. | C Min. | C Max. | Max. Recom. Normal Load (lb.) |

| 1 1/2 | 6 | 2 1/6 | 1 5/8 | 15 1/2 | 20 1/2 | 3000 |

| – | 12 | – | – | 19 1/2 | 29 1/2 | – |

| – | 18 | – | – | 19 1/2 | 29 1/2 | – |

| 2 1/2 | 6 | 2 1/2 | 2 1/4 | 15 7/8 | 20 7/8 | 10000 |

| – | 12 | – | – | 19 1/2 | 29 1/2 | – |

| – | 18 | – | – | 19 1/2 | 29 1/2 | – |

| 3 1/4 | 6 | 3 1/4 | 3 | 17 5/8 | 22 5/8 | 20000 |

| – | 12 | – | – | 22 5/8 | 32 5/8 | – |

| – | 18 | – | – | 22 5/8 | 32 5/8 | – |

| 4 | 6 | 4 | 3 3/4 | 19 1/2 | 24 1/2 | 30000 |

| – | 12 | – | – | 24 1/2 | 34 1/2 | – |

| – | 18 | – | – | 24 1/2 | 34 1/2 | – |

| 5 | 6 | 5 1/18 | 4 1/2 | 21 | 26 | 50000 |

| – | 12 | – | – | 26 | 36 | – |

| – | 18 | – | – | 26 | 36 | – |

| 6 | 6 | 5 3/4 | 5 1/2 | 23 5/8 | 28 5/8 | 70000 |

| – | 12 | – | – | 28 5/8 | 38 5/8 | – |

| – | 18 | – | – | 28 5/8 | 38 5/8 | – |

| 8 | 6 | 7 1/4 | 6 | 28 7/8 | 33 7/8 | 130000 |

| – | 12 | – | – | 33 7/8 | 43 7/8 | – |

| – | 18 | – | – | 33 7/8 | 43 7/8 | – |

*Loads must not be applied outside a 10° included angle cone of action to the pipe clamp axis w/o special authorization

E-takeout for Fig. 2100 Hydraulic Snubbers and Sway Strut Assemblies

| Pipe Size | 1 1/2 | 2 1/2 | 3 1/4 | 4 | 5 | 6 | 8 |

|

3/4

|

2 7/16 | – | – | – | – | – | – |

|

1

|

2 9/16 | – | – | – | – | – | – |

|

1 1/4

|

2 11/16 | – | – | – | – | – | – |

|

1 1/2

|

4 1/8 | – | – | – | – | – | – |

|

2

|

5 1/8 | 5 | 6 3/8 | 6 3/8 | – | – | – |

|

2 1/2

|

5 3/8 | 6 1/2 | 7 | 7 1/2 | 8 1/8 | – | – |

|

3

|

5 15/16 | 7 | 7 | 7 1/2 | 8 3/8 | – | – |

|

4

|

6 1/2 | 7 | 7 1/4 | 7 1/4 | 8 3/8 | – | – |

|

5

|

7 | 7 | 7 3/4 | 7 3/4 | 9 1/8 | – | – |

|

6

|

8 9/16 | 8 9/16 | 9 1/4 | 9 1/4 | 10 | 11 | – |

|

8

|

9 9/16 | 9 9/16 | 10 1/8 | 10 1/8 | 11 1/4 | 12 | – |

|

10

|

10 7/16 | 10 7/16 | 11 3/8 | 11 3/8 | 12 3/4 | 14 1/4 | 15 |

|

12

|

– | 11 4/9 | 12 4/7 | 12 4/7 | 13 7/8 | 15 | 15 3/4 |

|

14

|

– | 12 11/18 | 13 1/2 | 13 1/2 | 14 1/2 | 15 | 16 1/2 |

|

16

|

– | 13 2/3 | 14 7/8 | 14 7/8 | 15 1/4 | 16 | 17 1/2 |

|

18

|

– | 14 11/16 | 15 1/2 | 15 1/4 | 16 3/4 | 16 3/4 | 18 1/2 |

|

20

|

– | 15 7/8 | 15 7/8 | 16 1/2 | – | – | – |

|

24

|

– | 17 7/8 | 17 7/8 | 19 5/16 | 20 | 22 | 22 |

|

30

|

– | 23 3/8 | 23 3/8 | 23 3/4 | 24 1/4 | 25 | 26 1/4 |

|

36

|

– | 28 3/4 | 28 3/4 | 28 3/4 | 30 3/4 | 32 3/4 | 32 3/4 |

|

|

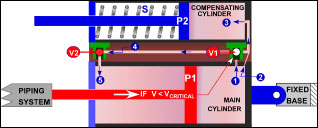

| Schematic of Hydraulic Snubber under normal conditions |

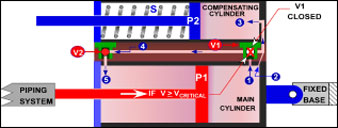

Schematic of Hydraulic Snubber under locked conditions |

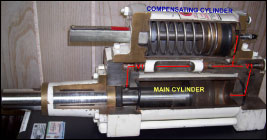

Hydraulic Snubber Test Machine

The Hydraulic Snubber test machine is mainly used to perform testing for hydraulic snubbers, it has a similar test bed to the STADAS machine, however, it is not computer controlled. It is adequate to perform all the tests normally required for hydraulic snubbers, such as quality control and periodic tests that are sometimes required as part of plant maintenance programs. Mechanical snubbers can also be tested on this machine, but due to the complication of the process, mechanical snubbers testing is usually performed on the STADAS machine.