One common issue we see across our 1,000+ audits of operating plants is that mid and long-term maintenance issues are often sometimes created during initial plant construction. The issue is that construction is a very complex process with many, many opportunities for error. Anyone who has ever visited a laydown yard is certainly familiar with this issue.

Figure 1- Laydown Yard Photos

|

|

The following are a list of some of the issues that can occur:

- Improperly placed pipe supports

- Suppliers errors

- Improperly installed supports

- Design errors

- Incorrect material installed

The current process is for a walk-down to take place to catch as many of these errors as possible. The quality of this process is highly dependent on the knowledge and experience of those doing the walk down. However, even the best engineers are likely to miss something when covering the scale of a Refinery or Power Plant.

Piping Technology & Products has been at the forefront of using the latest technologies to provide better audit capabilities. In particular, we have been looking at how Laser Scanning can be used in the construction and maintenance of Industrial Piping Systems. Attached is a prior article on the growth of the Laser Scanning technology and why we believe it is now on Moore’s Law pace in terms of price/performance improvements due to large investments being made in LIDAR.

The pipelines which are most challenging to design are the High Energy and Critical Lines. These lines are typically designed using CAESAR software to design and model the performance of the line when in operation. If during the initial start-up of the plant, the line does not behave as modeled in CAESAR, there is likely to be some issue that should be resolved for the short, medium or long-term health of the plant.

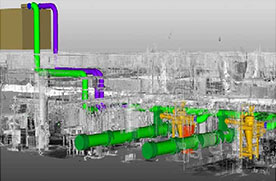

PT&P offers a service that compares a laser scan of a line both in operation and in the installed mode with the CAESAR model leveraging a new software tool designed to greatly facilitate this analysis. The analysis provides a detailed comparison of the CAESAR model with the as-built drawing from the laser scan. This includes the following:

- Accurate placement of the supports – the as-built and CAESAR model is overlaid allowing for a precision check of support placements

- Accurate placement of the Piping in the Cold position

- Measuring deflection from a base point in the model versus the as-built

Figure 2 – CAESAR Model and Piping Laser Scan

|

|

If there are variations from the as-built to the Caesar model, PT&P can diagnose the issues by:

- Checking placement of all elements when the line is not hot

- Recreating the as-built by modifying the CAESAR model-based PT&P experience (e.g. a spring with travel stop not pulled)

- Checking the temperature of the line versus design specification

Establishing the Baseline

With a validated CAESAR model, ongoing audits can be done by continuing the same comparison to the CAESAR model periodically. In addition, as changes are made to the plant, PT&P would recommend an update to the CAESAR model to ensure the proper functioning of the line and acceptable stress being placed on moving equipment.

PT&P offers highly cost-effective services for Pipe Stress Analysis and Laser Scanning. If you would like to discuss this further, call and speak with one of our expert engineers at 713-731-0030.