Download Slide Plates General Information

Slide bearing plates are a very cost-effective way of providing for movement of mechanical systems. Piping Technology & Products, Inc. supplies slide bearing plates for a variety of applications including support of piping, heavy equipment such as pressure vessels, and structural steel members. The plates provide a surface with a low coefficient of friction which can be attached to a supporting structure. This combination provides support while simultaneously allowing an object to move (slide) freely along the supporting surface.

Most designers use the “sandwich” concept when applying slide plates to their systems. Diagram A (on Page 192) shows a “sandwich” composed of two identical slide plates, one on top and another on the bottom. Each slide plate is composed of two components: a metal backing plate (which is like the bun of the “sandwich”) and a low coefficient of friction material which is bonded to the metal backing plate.

Diagram A: Sandwich Concept

Diagram A: Sandwich Concept

In a typical application, a slide bearing plate is welded to a structural steel member which is strong enough to provide the required support, but whose coefficient of friction is too high. When the pipe supported by the member moves (due to thermal expansion, for example) it slides across the surface of the bearing plate without contacting the steel beam. To return to our “sandwich” metaphor, the top half of the “sandwich” is bonded to the pipe, and the bottom half to the steel beam.

One combination of materials that we recommend is that of PTFE, 25% glass filled, bonded to stainless steel. Both materials resist oxidation and have long lives even in stressful environments. For large slide plates, galvanized steel can be used in place of stainless to reduce the cost.

|

Slide Plate Selection Chart

|

|||

|

Temperature

|

Max Load

|

Coefficient of Friction

|

|

| PTFE, 25% Glass Filled |

-320°F to +500°F

|

Loads up to 2,000 PSI

|

.01 to .2 |

| Bronzphite® |

up to 1,100°F

|

Loads up to 5,000 PSI

|

.15

|

| Graphite |

+1,000°F Air & +3,000°F Inert

|

Loads up to 2,000 PSI

|

.15

|

| Stainless Steel |

up to 1500°F

|

Loads up to 5,000 PSI

|

0.08 @ Min. Pressure

0.06 @ Max. Pressure

(polished) |

| Marinite |

+400°F to +800°F

|

100 PSI to 2,500 PSI

|

0.08 @ Min. Pressure

0.06 @ Max. Pressure

|

Assembly Basics

Slide plates are usually arranged in what is known as a ‘sandwich’ formation, which consists of an upper slide plate component and a lower slide plate component.

The lower slide plate may also be welded to a stationary support (i.e. structural steel member), which grounds the plate, while the other plate is attached to the moving component directly. As the system moves, friction is transferred at the intersection of the two plates.

When ordering, always specify the dimensions of the upper and lower slide plate. As a rule, the upper slide plate should be large enough to completely cover the lower plate at all times.

Recommended Applications / Temperature Limits

-320F to +500F with low PSI

Different plates are suited for different temperature limits. While all plates have been rigorously tested for suitability within industrial settings, understanding the particular variables of that setting is vital to purchasing the appropriate plate for each application.

TEMPERATURE CONSIDERATIONS

PTFE, 25% glass filled, provides a low coefficient of friction for most combinations of temperature and load. Diagram B, on Page 193, shows the recommended conditions for 3/32” PTFE, 25% glass filled. For most applications, PTFE, 25% glass filled, is adequate when the temperature is less than 400 °F. When the slide bearing plate must function at higher temperatures, graphite can be used instead of PTFE, 25% glass filled. The load-bearing capacity of graphite is not sensitive to increases in temperature, but the adhesive used to bond the graphite to its metal backing is. It is good practice to use additional mechanical fasteners such as counter-sunk screws to help hold the graphite in place when the temperatures are above 500 °F. For combinations of temperature and load beyond the capabilities of graphite, special designs must be considered.

ATTACHMENT CONSIDERATIONS

Welding is the most common method of attaching the slide bearing plate to supporting metal structures. When this approach is used a slide plate must be designed with a “lip” since the welding’s extreme temperature may break the bond between the low-friction material and the metal plate. A 1/4” “lip” is adequate for most welded installations. When welding cannot be used (for safety or other reasons) to attach the slide plates, bolting is the most common substitute.

Before we begin constructing your slide bearing plates, we need to know the following:

• The material you desire for the low-friction surface, based on the highest combinations of temperature and load the component will experience.

• The desired size and shape for the low-friction surface.

• The type of metal, size, and shape you desire for the backing steel. Most designers choose galvanized or stainless steel.

Slide bearing plates are components of many products Piping Technology & Products, Inc. supplies such as guided pipe shoes and upthrust constants. As a result, we have extensive experience in bonding PTFE, 25% glass filled, and graphite to metal plates. Modern adhesives are adequate for most applications. However, mechanical fasteners such as countersunk screws can be added when needed. If you have unique applications, we will be happy to custom design a practical solution for your application.

NON-STANDARD ASSEMBLY CONFIGURATIONS

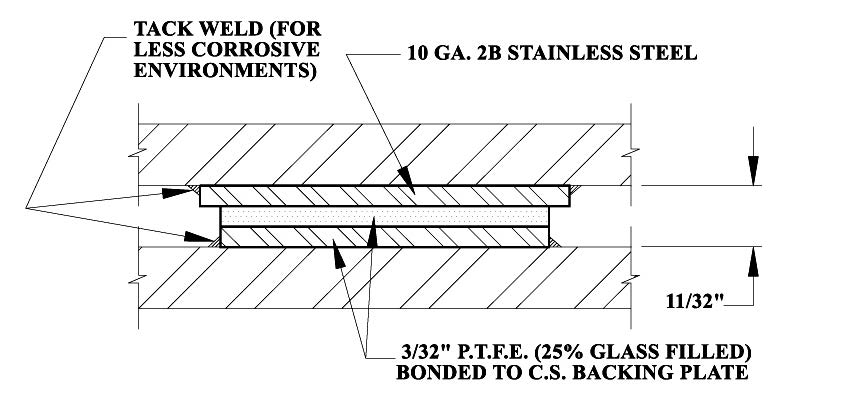

Slide Plates for Higher Load Capacities

Notes:

1. Pressure range: 75 PSI to 2,200 PSI

2. Temperature range: -320 °F to 400 °F

3. Alternate backing materials are available.

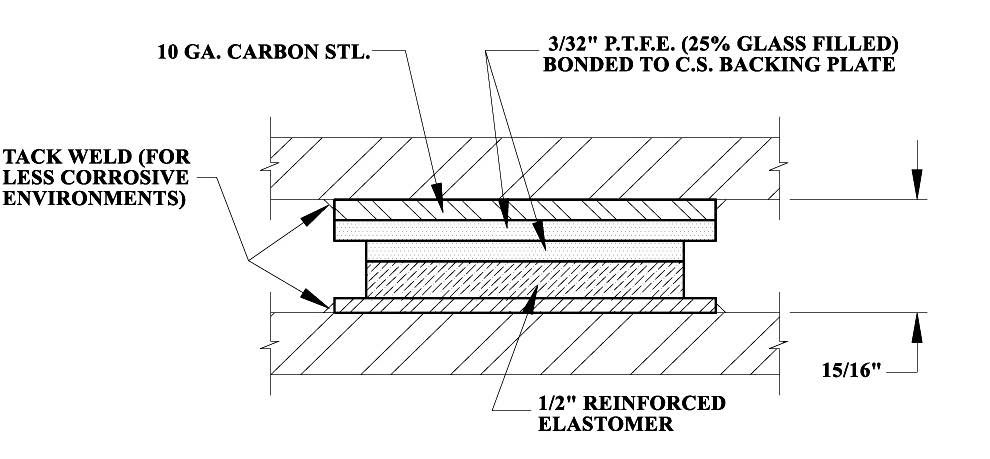

Slide Plates for Deflection & Expansion at Higher Loads

Notes:

1. Pressure range: 75 PSI to 1,500 PSI

2. Temperature range: -50 °F to 200 °F

3. Alternate thicknesses of reinforced elastomer available.

Slide Plates For Welding To Mating Surfaces

Notes:

1. Pressure range: 75 PSI to 2,000 PSI

2. Temperature range: -320 °F to 400 °F

3. Alternate backing materials are available.

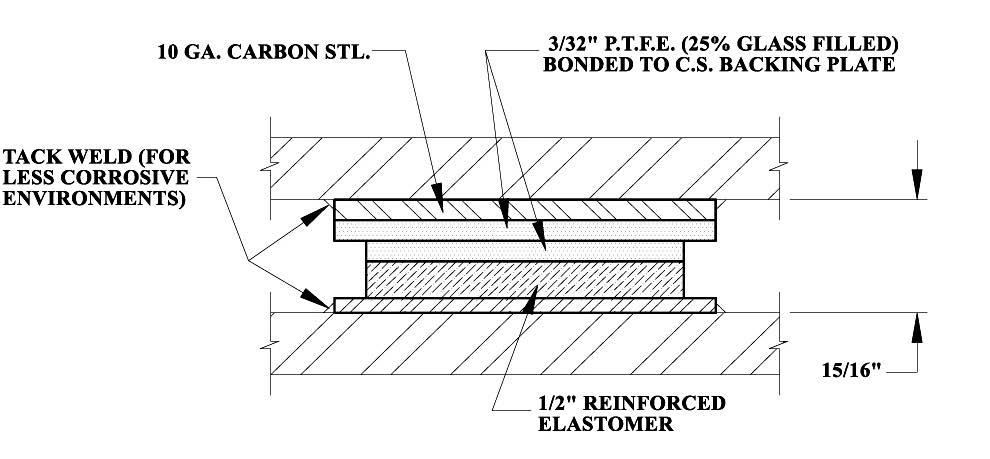

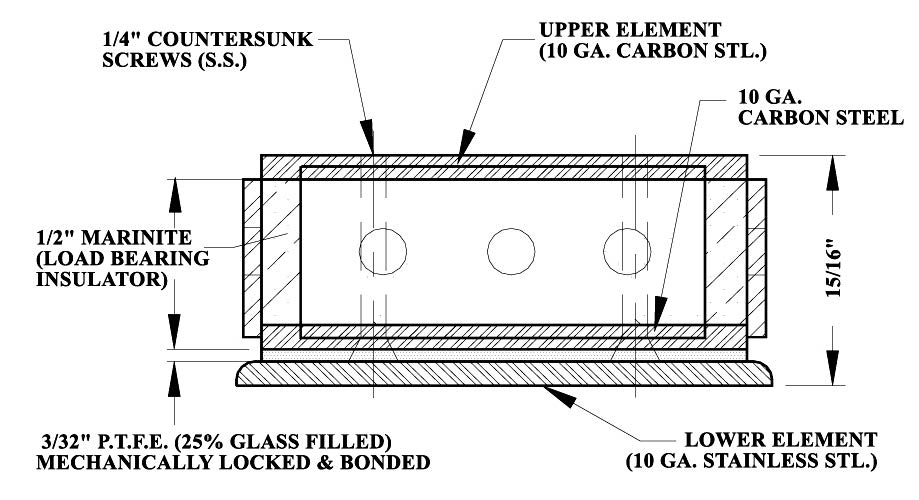

Slide Plates For High Temperature & High Load Bearing

Notes:

1. Pressure range: 100 PSI to 2,500 PSI

2. Temperature range 1/2” insulator: 400 °F to 800 °F

3. Coefficient of friction:

0.08 @ min. pressure

0.06 @ max. pressure