Expansion Joints are PT&P’s largest individual and most engineered product category (though we are in a lot of categories) You can find many of our projects in our U.S. Bellows product archives. Expansion joints are also the product that PT&P started its business with when our founder designed a thick-walled Expansion Joint for Dow Plaquemine in 1974. PT&P now sells expansion joints through Its U.S. Bellows subsidiary. PT&P is uniquely positioned to service Expansion Joint Requirements as we are the only company globally that has deep Pipe Stress Engineering Expertise AND produces expansion joints and Engineered Pipe Supports. Also, PT&P is one of only 14 global members of the Expansion Joint Manufacturer’s Association which sets the de facto standards for Expansion Joint Engineering. There are many providers of expansion joints but only a very limited number of those who have the Engineering capability to be a participating member of EJMA.

Our recommendation for our customers is to only use expansion joints when necessary as they are the weakest link in the Piping System.

Our Expansion Joint Offerings Include:

- Expansion Joint Inspections

- Expansion Joint Design and Manufacturing

- Expansion Joint Engineering and Pipe Stress Analysis

Beyond the product itself, US Bellows offers the following complimentary services as part of the product purchase:

- Expansion Joint Design Advice

- Installation and Maintenance Support

- Troubleshooting Support

- Material Selection Support

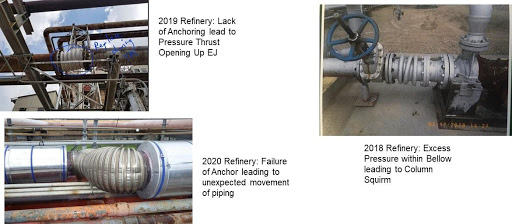

- US Bellows has extensive experience in the issues that plants experience with Expansion Joints. Here are some of the issues that trouble customers the most (Expansion joint failures).

In addition, PT&P’s Field Services is your one-stop solution to all your expansion joint needs, including survey/audits, installation, replacement, engineering, and design from start to finish. Some points on our inspection checklist are:

- check for signs of leakage or a loss of pressure

- inspect for any distortion or yielding of anchors, hardware, bellows, and piping connection points

- observe for any unanticipated movement of piping due to pressure

- inspect for evidence of instability (squirm), distortion or damage in the bellows convolutions

- check the expansion joint, the guides, and other moveable parts of the system for evidence of binding

- check for misalignment of the expansion joint unit

- check for vibration damage

Expansion Joint Basics

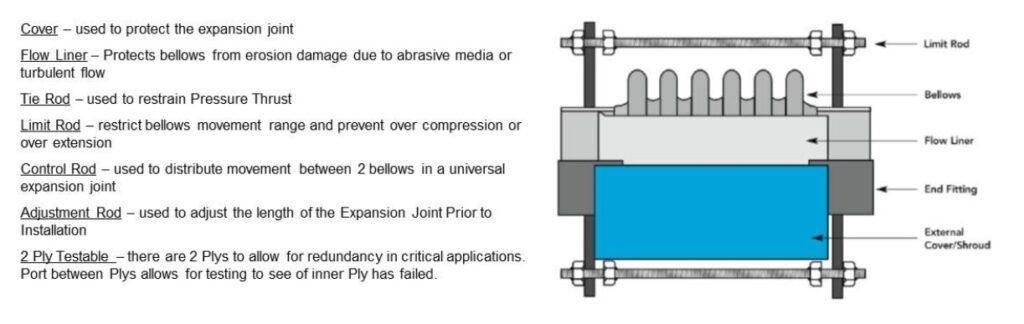

The chart below shows the basic elements of an expansion joint. It is important to note that the picture shows a limit rod but that in different configurations, the rod can be a tie rod, limit rod, control rod, or adjustment rod. In this case of a tie rod, the rod is used to restrain pressure thrust but in this configuration, it does not allow for axial movement.

The types of movement supported by an expansion joint are shown below. The last movement, torsional, is not supported by expansion joints and the piping design should not place excess torsional force on the expansion joint.

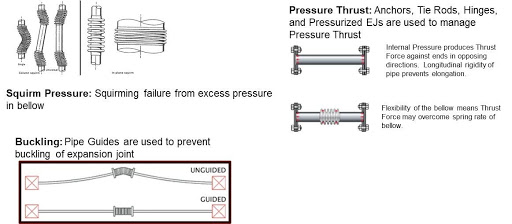

The following are 3 key issues that must be managed when expansion joints are introduced into the piping system:

- Pressure thrust is the natural pressure on the ends of the piping from the media seeking to expand when under pressure. Pressure thrust becomes an issue because it can overcome the spring rate of the expansion joint.

- Squirm pressure is the force the media is placing on bellow which becomes a key design constraint in high-pressure systems and can lead to specific failures if the squirm pressure is too high.

- Buckling is the potential for the bellow to buckle if its movement is not properly constrained or guided.

The pictures below are of real-life examples of failures due to these issues:

Expansion Joint Design

Expansion joints are the most highly engineered pipe stress component. As one of only 14 members of the expansion joint manufacturer’s association, all PT&P expansion joints are designed and built to EJMA standards. The key to the functioning of an expansion joint starts with the convolutions which function as a small expansion loop.

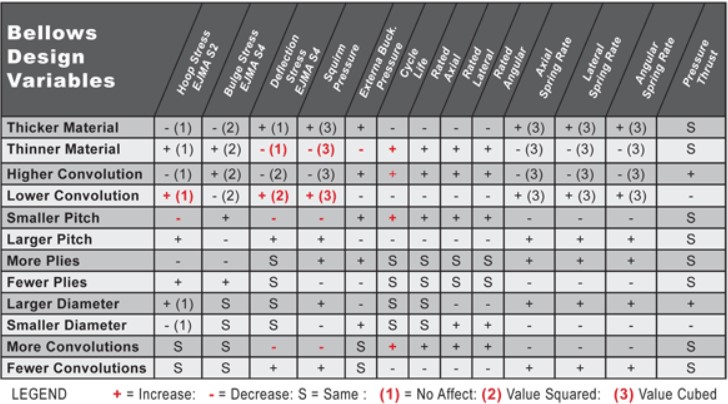

The table below shows all the tradeoffs that are used in designing a bellow. This does not even take into account the tradeoffs made in selecting the Expansion Joint Type. If customers are able to consult PT&P upfront, then we can do more to make the right tradeoffs in the overall design.

Specifying Expansion Joints in Caesar

Specifying expansion joints in caesar is very different than other pipe stress-related components such as spring supports. Caesar can not auto-specify EJs the way it does spring supports. Caesar treats expansion joints much more simplistically.

Generally, pipe stress engineers will hand calculate the movements to be absorbed by EJs. They will then design an expansion joint. The table below shows the thermal expansion for different materials. For example, 1000 linear feet of 304SS piping which increases 100F in temperature will undergo approximately 11.5 inches of thermal expansion which must be accounted for in the piping system.

When an expansion joint has been selected, caesar will ask users to specify spring rates and tie rod elements for the expansion joint. Caesar WILL NOT protect users from errors such as placing excess torsion on the expansion joint. This case study is an example of a caesar model in which there were challenges in expansion joint design.

Expansion Joint Maintenance

Only a limited amount of inspection can be done during operations. This includes:

- Visual inspection for cracks, corrosion, and proper functioning within system design during operation

- Pressure testing between plys for 2 ply testable expansion joints during operation

- Comparison of Laser Scan as-built to Caesar to insure proper line and functioning

- Dye Pen, Ultrasonic, and X-Ray testing of Welds during Turnarounds

Given the severity of a potential EJ failure, US Bellows recommends a regular replacement cycle and can assist with this recommendation based on its data on EJ service histories. One of the most important preventative maintenance issues with EJs is insuring that spring supports that have a major impact on the functioning of the EJ are properly maintained.

Types of Expansion Joints

Expansion joint materials include metallic, fabric, rubber, and PTFE. US Bellows offers metallic, fabric, and rubber expansion joints. PTFE expansion joints are most commonly found in chemical plants to accommodate highly corrosive media.

A wide variety of materials are used in metallic expansion joints. The table below shows the standard materials that US Bellows stocks for metallic expansion joints. US Bellow has extensive expertise in metallurgy selection and has assisted many customers in selecting the optimal material for a particular design challenge.

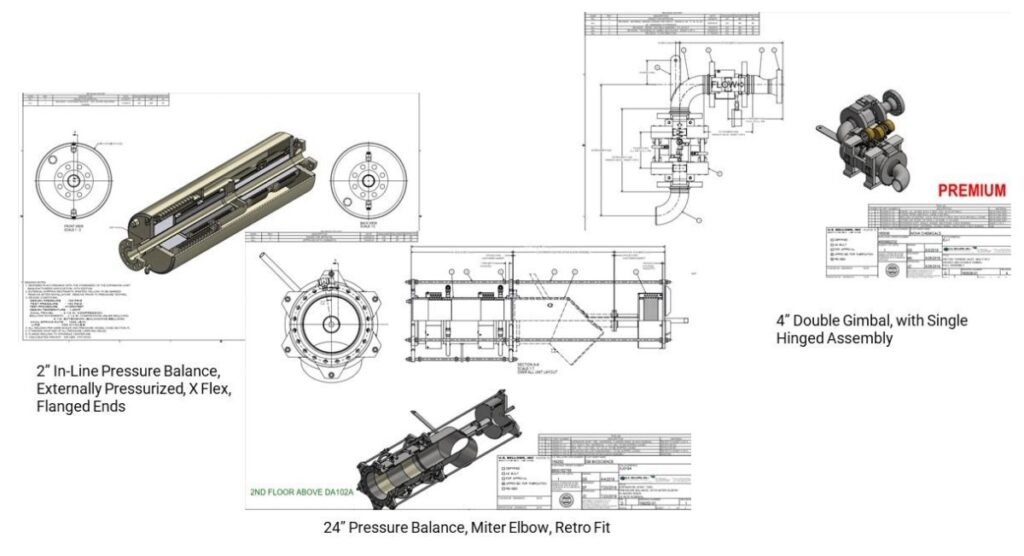

Types of standard metallic expansion joints include single expansion joint, universal expansion joint, hinged expansion joint, gimbal expansion joint, in-line pressure balanced expansion joint, elbow pressure balanced expansion joint, externally pressurized expansion joint, slip type expansion joint, and rectangular expansion joint.

- Single expansion joint – is the most common and simple type of expansion joint. The downside is that it is limited the amount of movement it supports effectively.

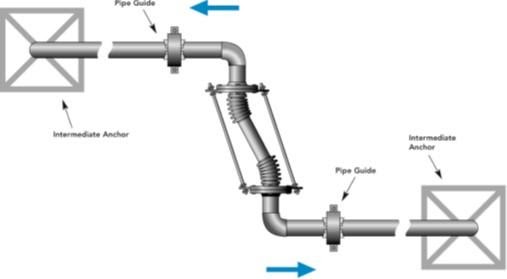

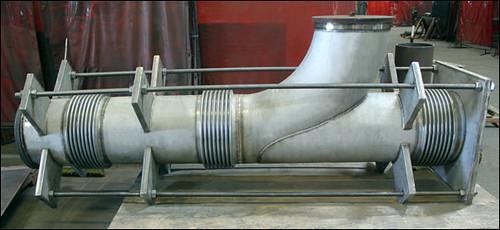

- Universal expansion joint – this type of expansion joint is used to support larger degrees of lateral movement. NOTE how the control rods in a Universal EJ are used to distribute movement between the 2 bellows.

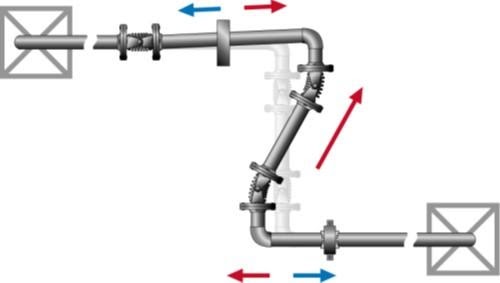

- Hinged expansion joint – this type of expansion joint is used to constrain the movement to one plane of angular movement. In addition, the hinge mechanism restrains pressure thrust and can be used to bear weight by the Piping Designer.

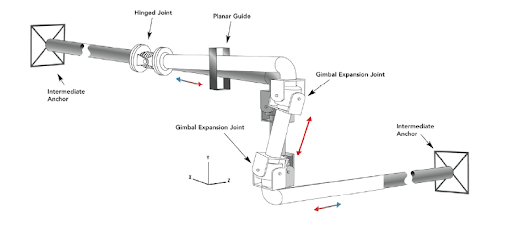

- Gimbal expansion joint – this type of expansion joint is used to constrain the movement to two planes of angular movement. In addition, the gimbal mechanism restrains pressure thrust and can be used to bear weight by the Piping Designer. Gimbal EJs are most commonly found in some Refinery FCC designs.

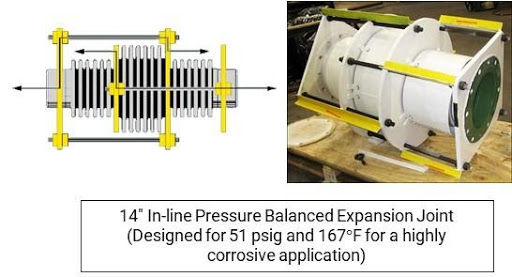

- In-Line pressure balanced expansion joint – This is a type of expansion joint that is used to restrain pressure thrust while allowing for axial compression and expansion. The inner and outer bellows work together to simultaneously restrain pressure thrust and allow axial movement. In-line pressure balanced EJ is useful when there is no room for anchoring. US Bellows sees these EJs used around sensitive equipment such as Turbines and Compressors.

- Elbow pressure balanced expansion joint – these have a similar function to an in-line pressure balanced EJ to allow for axial movement while also restraining pressure thrust.

- Externally pressurized expansion joint – with these expansion joints, the media flows through an integral liner and does not flow through the inside of the bellow. As a result, these bellows offer the following advantages:

- Support higher pressure applications

- Allow for higher levels of axial movement due to lack of squirm pressure

- A hardened exterior offers better resistance to difficult environments

- Media can be drained during turnarounds to limit damage to bellows

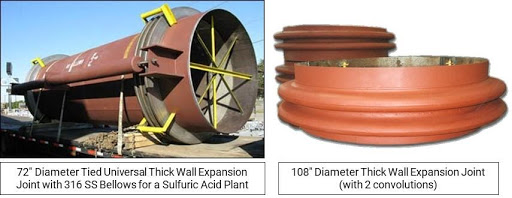

- Thick-walled expansion joints – these can be used to provide longer life in challenging environments. Thick-walled EJs will have higher spring rates which must be taken into account in the design phase.

- Rectangular expansion joints – these have a variety of applications in the power, petrochemical, refining, chemical, and steel industries in ducting.

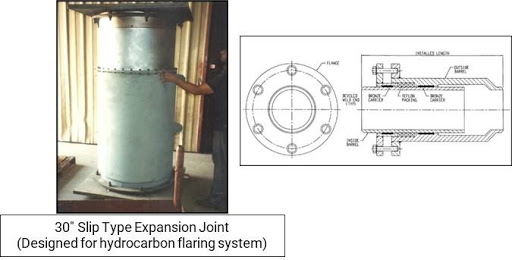

- Slip-Type expansion joints – these are used to support large axial movement in ducting systems. Design details include a selection of packing and seals and perhaps resistance to abrasive solids. Special features such as “wipers” can be included to prevent potential clogging of the space provided for slip movement.

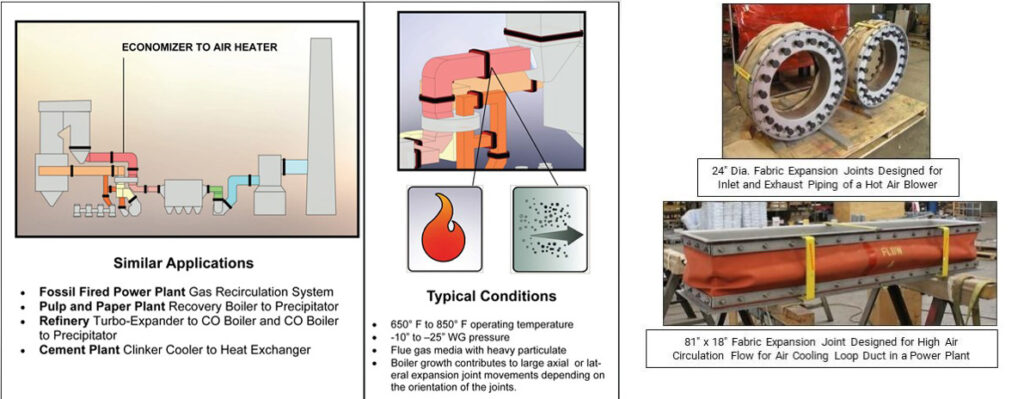

Fabric Expansion Joints

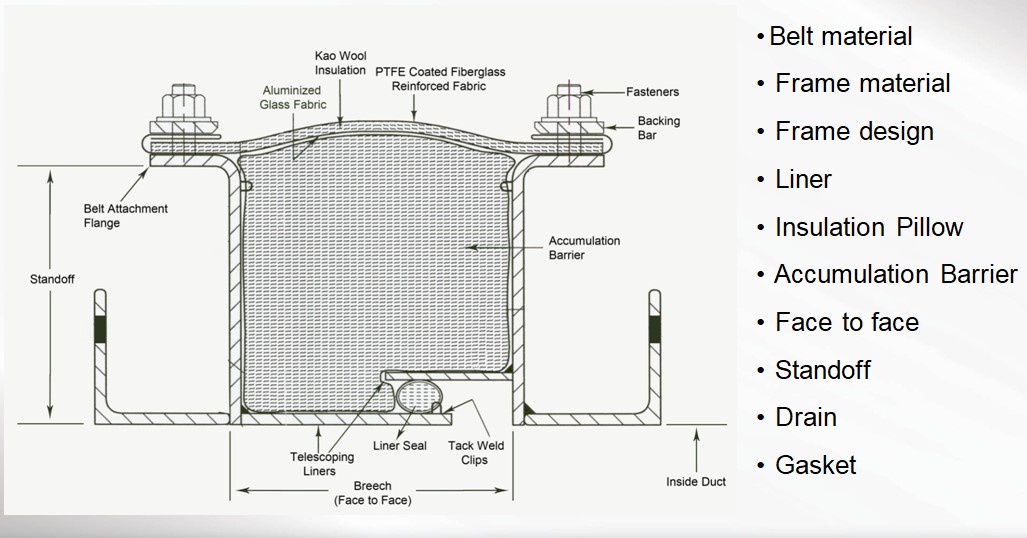

Fabric expansion joints are commonly used in low-pressure environments such as exhaust and ducting. The major advantage of fabric expansion joints is that they support a large degree of movement in a limited space. They also allow for easy replacement of fabric without a replacement of the Fabric EJ frame.

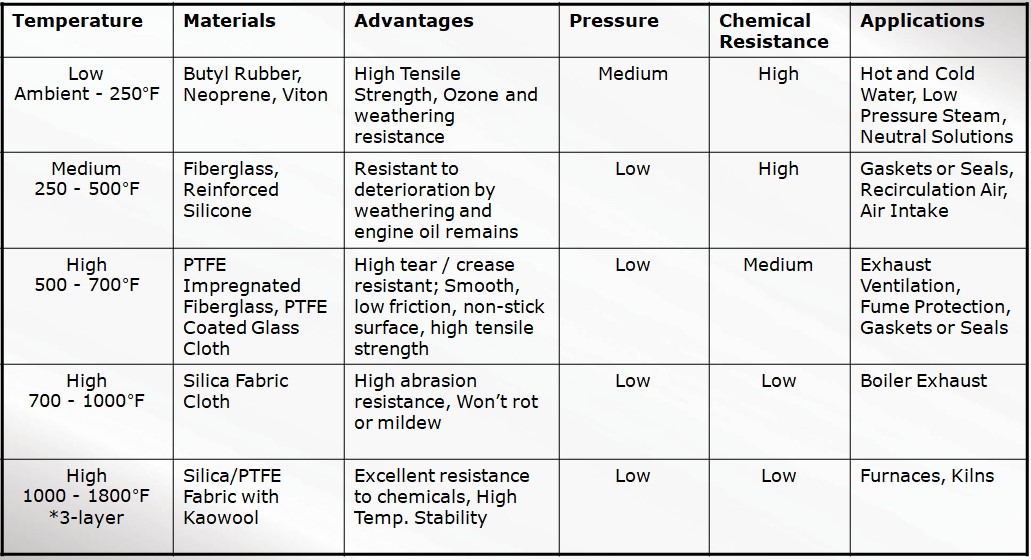

There is a wide variety of materials used in fabric EJs to support different design conditions as shown in the table below.

Rubber Expansion Joints

US Bellows also offers rubber EJs for environments where rubber better suits the conditions.

Custom Expansion Joints

Without our unique engineering expertise in expansion joints, pipe stress, and engineered pipe supports, PT&P/US Bellows had developed hundreds of custom designs for unique customer requirements.