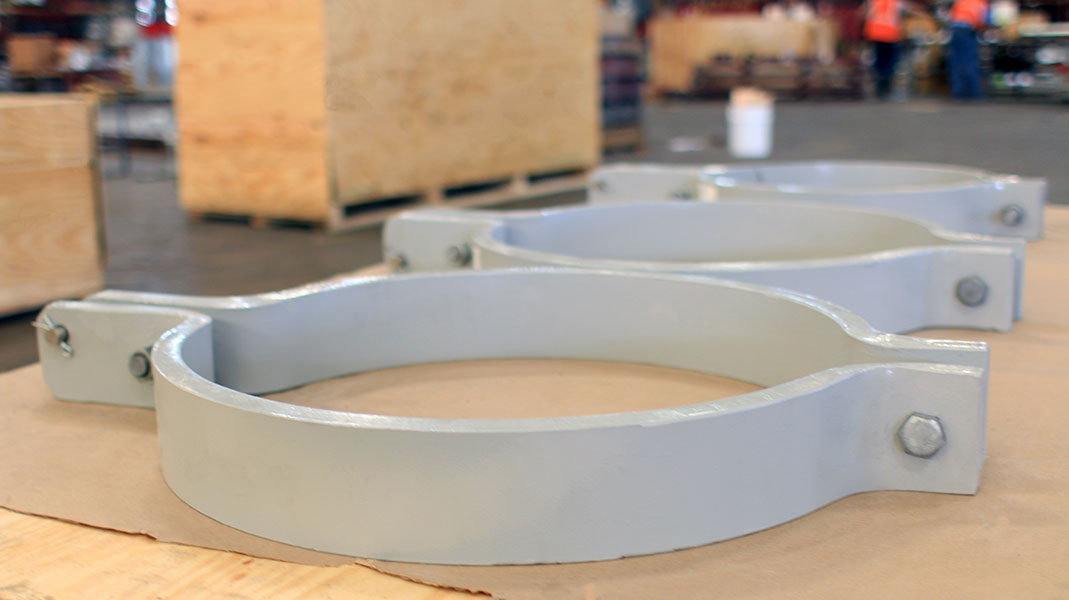

Pipe Clamps & Risers

A pipe clamp is a bolted pipe attachment which clamps around the pipe to connect the pipe to the remainder of a pipe hanger assembly. Piping Technology & Products, Inc. maintains an extensive inventory of pipe clamps required for pipe hanger and support assemblies. The pipe clamps and risers can be manufactured with galvanized or black finishes depending upon customer specifications.

Acid Plants

Ammonia Plant

Chemical Plant

Clean Fuels

Cogeneration Plant

Cold / Cryogenc Service

Commercial

Electric Plant

Energy Facility

Ethylene Plant

Heat Recovery Steam Generation Plant

Hospital

LLDPE Chemical Plant

LNG Plant

MTBE Plant

See All

A pipe clamp is a pipe attachment which clamps around the pipe to connect the pipe to the remainder of ...Continue Reading

When using pipe clamps as part of an anchoring assembly, the resistance to the pipe movement can be developed in ...Continue Reading

The most common method for supporting vertical piping would be to first weld shear lugs into position, and then utilize ...Continue Reading

Riser clamps are a two point load bearing component and are usually used for vertical running pipe lines wherein shear ...Continue Reading

More FAQs…

GENERAL DIMENSIONS & SPECIFICATIONS

- Fig. 2: Adjustable Band Hanger

- Fig. 42: Yoke U-Bolt

- Fig. 43: Heavy Duty Yoke U-Bolt

- Fig. 50: Light Two Bolt Pipe Clamp

- Fig. 60: Heavy Two Bolt Clamp

- Fig. 70: Light Three Bolt Pipe Clamp

- Fig. 70A: Alloy Three Bolt Pipe Clamp

- Fig. 80: Heavy Three Bolt Pipe Clamp

- Fig. 90: Riser Clamp

- Fig. 190: Fabricated Riser Clamp

Fig. 2: Adjustable Band Hanger

ADJUSTMENT: This hanger provides for a vertical adjustment of 1 to 2 inches with the pipe and hanger in position. A temporary support is not required while adjustment is being made.

FINISH: Hangers can be furnished galvanized. Specify when ordering.

ORDERING: Specify figure number, pipe size and description.

| PIPE SIZE | A | B | C | D | E | WGT. / C APPROX. | MAX. RECOM. LOAD (lb.) |

|---|---|---|---|---|---|---|---|

| 1/2 | 3/8 | 1 13/16 | 2 5/16 | 2 1/2 | 1 1/8 | 10 | 610 |

| 3/4 | 3/8 | 2 1/16 | 2 5/8 | 2 1/2 | 1 5/16 | 14 | 610 |

| 1 | 3/8 | 2 3/16 | 2 7/8 | 2 1/2 | 1 7/16 | 15 | 610 |

| 1 1/4 | 3/8 | 2 9/16 | 3 7/16 | 2 1/2 | 1 13/16 | 18 | 610 |

| 1 1/2 | 3/8 | 2 3/4 | 3 11/16 | 2 1/2 | 1 15/16 | 23 | 610 |

| 2 | 3/8 | 3 | 4 3/16 | 2 1/2 | 2 3/16 | 24 | 610 |

| 2 1/2 | 1/2 | 3 7/8 | 5 5/16 | 3 1/2 | 3 | 35 | 970 |

| 3 | 1/2 | 4 1/4 | 6 | 3 1/2 | 3 5/16 | 36 | 970 |

| 3 1/2 | 1/2 | 4 1/2 | 6 1/2 | 3 1/2 | 3 9/16 | 37 | 970 |

| 4 | 5/8 | 4 7/8 | 7 1/8 | 4 | 3 13/16 | 84 | 1250 |

| 5 | 5/8 | 5 11/16 | 8 7/16 | 4 | 4 5/8 | 93 | 1250 |

| 6 | 3/4 | 6 3/8 | 9 11/16 | 4 1/2 | 5 3/16 | 171 | 1600 |

| 8 | 7/8 | 7 9/16 | 11 7/8 | 4 1/2 | 6 3/16 | 271 | 1800 |

| 10 | 7/8 | 8 5/8 | 14 3/16 | 4 1/2 | 6 3/16 | 319 | 1800 |

| 12 | 7/8 | 9 5/8 | 16 1/4 | 4 1/2 | 6 3/16 | 478 | 1800 |

Fig. 42: Yoke U-Bolt

MATERIAL: Yoke, load bolt and load distribution strap is chrome molybdenum steel. U-Bolt is stainless steel.

SERVICE: Recommended for suspension of high temperature piping requiring 4 to 6 inches of insulation.

MAX. TEMP: 1100°F

ORDERING: Specify figure number, pipe size and description.

| FIG. 42 | STANDARD | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PIPE SIZE | MAX. RECOM. LOAD (lbs.) | B | C | D | E | F | G | H | APPROX. WEIGHT (lbs. per 100) | ||

| @ 950° F | @ 1050°F | @ 1100° F | |||||||||

| 8 5/8 – 10 13/16 | 9500 | 9100 | 8800 | 9 1/2 | 2 | 4 | 13 3/4 | 1 1/2 | 7/8 | 14 1/2 | 4900 |

| 10 7/8 – 12 13/16 | 9500 | 9100 | 8800 | 10 1/2 | 2 | 4 | 14 3/4 | 1 1/2 | 7/8 | 16 1/2 | 5400 |

| 12 7/8 – 14 1/8 | 9500 | 9100 | 8800 | 11 1/4 | 2 | 4 | 15 1/2 | 1 1/2 | 7/8 | 18 | 5900 |

| 14 3/16 – 16 1/8 | 12500 | 12000 | 11500 | 13 | 2 1/4 | 5 | 16 3/4 | 1 3/4 | 1 | 21 | 10400 |

| 16 3/16 – 18 1/8 | 12500 | 12000 | 11500 | 14 | 2 1/4 | 5 | 17 3/4 | 1 3/4 | 1 | 23 | 11300 |

| 18 3/16 – 20 1/4 | 12500 | 12000 | 11500 | 15 | 2 1/4 | 5 | 18 3/4 | 1 3/4 | 1 | 25 | 12500 |

| 20 5/16 – 22 1/4 | 15500 | 15000 | 14500 | 16 1/2 | 2 1/4 | 5 | 20 | 2 | 1 1/8 | 28 | 16200 |

| 22 5/16 – 24 1/4 | 15500 | 15000 | 14500 | 17 1/2 | 2 1/4 | 5 | 21 | 2 | 1 1/8 | 30 | 17600 |

| 24 5/16 – 26 1/4 | 15500 | 15000 | 14500 | 18 1/2 | 2 1/4 | 5 | 22 | 2 | 1 1/8 | 32 | 19300 |

| 26 5/16 – 28 1/4 | 20000 | 19200 | 18500 | 20 | 2 1/2 | 6 | 23 3/4 | 2 1/4 | 1 1/4 | 34 1/2 | 27400 |

| 28 5/16 – 30 1/4 | 20000 | 19200 | 18500 | 21 | 2 1/2 | 6 | 24 3/4 | 2 1/4 | 1 1/4 | 36 1/2 | 29800 |

Fig. 43: Heavy Duty Yoke U-Bolt

MATERIAL: Yoke, load bolt and load distribution strap is chrome molybdenum steel. U-Bolt is stain-less steel.

SERVICE: Recommended for suspension of high temperature piping requiring 4 to 6 inches of insulation.

MAX. TEMP: 1100°F

ORDERING: Specify figure number, nominal pipe size, and description.

NOTE: Strap provided on Fig. 43 only.

| FIG. 43 | HEAVY DUTY | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PIPE SIZE | MAX. RECOM. LOAD (lbs.) | B | C | D | E | F | G | H | APPROX. WEIGHT (lbs. per 100) | ||

| @ 950° F | @ 1050° F | @ 1100° F | |||||||||

| 8 5/8 – 10 13/16 | 13500 | 12000 | 11500 | 10 1/4 | 2 1/4 | 5 | 14 | 1 3/4 | 1 | 15 1/4 | 7200 |

| 10 7/8 – 12 13/16 | 16500 | 15000 | 14500 | 11 3/4 | 2 1/4 | 5 | 15 1/4 | 2 | 1 1/8 | 17 3/4 | 10300 |

| 12 7/8 – 14 1/8 | 16500 | 15000 | 14500 | 12 1/2 | 2 1/4 | 5 | 16 | 2 | 1 1/8 | 19 1/4 | 11000 |

| 14 3/16 – 16 1/8 | 20000 | 19200 | 18500 | 13 3/4 | 2 1/2 | 6 | 17 1/2 | 2 1/4 | 1 1/4 | 22 | 16700 |

| 16 3/16 – 18 1/8 | 20000 | 19200 | 18500 | 14 3/4 | 2 1/2 | 6 | 18 1/2 | 2 1/4 | 1 1/4 | 24 | 18000 |

| 18 3/16 – 20 1/4 | 23700 | 22700 | 21900 | 16 | 2 3/4 | 6 1/2 | 20 | 2 1/2 | 1 3/8 | 26 1/2 | 22800 |

| 20 5/16 – 22 1/4 | 23700 | 22700 | 21900 | 17 | 2 3/4 | 6 1/2 | 21 | 2 1/2 | 1 3/8 | 28 1/2 | 24600 |

| 22 5/16 – 24 1/4 | 29000 | 28000 | 27000 | 18 1/2 | 3 | 7 | 22 3/4 | 2 3/4 | 1 1/2 | 30 3/4 | 32500 |

| 24 5/16 – 26 1/4 | 29000 | 28000 | 27000 | 19 1/2 | 3 | 7 | 23 3/4 | 2 3/4 | 1 1/2 | 32 3/4 | 34000 |

| 26 5/16 – 28 1/4 | 29000 | 28000 | 27000 | 20 1/2 | 3 | 7 | 24 3/4 | 2 3/4 | 1 1/2 | 34 3/4 | 35500 |

| 28 5/16 – 30 1/4 | 29000 | 28000 | 27000 | 21 1/2 | 3 | 7 | 25 3/4 | 2 3/4 | 1 1/2 | 36 3/4 | 36900 |

| 36 | 29000 | 28000 | 27000 | 24 1/2 | 3 | 7 | 28 1/2 | 2 3/4 | 1 1/2 | 43 1/4 | 42000 |

Fig. 50: Light Two Bolt Pipe Clamp

SIZE RANGE: 1/2 inch thru 36 inches

MATERIAL: Carbon steel

FINISH: Black or galvanized; furnished black unless otherwise specified.

SERVICE: Recommended for suspension of cold pipe lines or hot lines where little or no insulation is required.

MAX. TEMP.: 750°F

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD, lbs. | B | C | D | E | F | STOCK SIZE | H | APPROX. WEIGHT | |

|---|---|---|---|---|---|---|---|---|---|---|

| @ 650° F | @ 750° F | G | lbs. per each | |||||||

| 1/2 | 500 | 445 | 1 | 1/2 | 1 17/32 | 1 | 5/16 | 1/8 x 1 | 1 17/32 | 0.29 |

| 3/4 | 500 | 445 | 1 1/8 | 1/2 | 1 21/32 | 1 1/8 | 5/16 | 1/8 x 1 | 1 21/32 | 0.33 |

| 1 | 500 | 445 | 1 1/8 | 1/2 | 1 29/32 | 1 3/8 | 5/16 | 1/8 x 1 | 1 21/32 | 0.35 |

| 1 1/4 | 500 | 445 | 1 7/16 | 1/2 | 1 31/32 | 1 7/16 | 5/16 | 1/8 x 1 | 1 31/32 | 0.37 |

| 1 1/2 | 800 | 715 | 1 9/16 | 1/2 | 2 5/32 | 1 5/8 | 5/16 | 1/8 x 1 | 2 3/32 | 0.43 |

| 2 | 1040 | 930 | 2 1/8 | 1/2 | 2 3/4 | 2 1/8 | 1/2 | 1/4 x 1 | 2 3/4 | 1.1 |

| 2 1/2 | 1040 | 930 | 2 1/2 | 5/8 | 3 1/4 | 2 5/8 | 1/2 | 1/4 x 1 | 3 1/8 | 1.2 |

| 3 | 1040 | 930 | 2 13/16 | 5/8 | 3 9/16 | 2 15/16 | 1/2 | 1/4 x 1 | 3 7/16 | 1.4 |

| 3 1/2 | 1040 | 930 | 3 1/8 | 5/8 | 3 13/16 | 3 3/16 | 1/2 | 1/4 x 1 | 3 3/4 | 1.5 |

| 4 | 1040 | 930 | 3 7/16 | 3/4 | 4 3/8 | 3 5/8 | 5/8 | 1/4 x 1 1/4 | 4 3/16 | 2.3 |

| 5 | 1040 | 930 | 4 | 3/4 | 4 15/16 | 4 3/16 | 5/8 | 1/4 x 1 1/4 | 4 3/4 | 2.6 |

| 6 | 1615 | 1440 | 4 7/8 | 7/8 | 5 7/8 | 5 | 3/4 | 3/8 x 1 1/2 | 5 3/4 | 5.4 |

| 8 | 1615 | 1440 | 6 | 1 | 7 | 6 1/8 | 3/4 | 3/8 x 1 1/2 | 6 7/8 | 6.5 |

| 10 | 2490 | 2220 | 7 5/16 | 1 | 8 9/16 | 7 7/16 | 7/8 | 1/2 x 2 | 8 7/16 | 13.6 |

| 12 | 2490 | 2220 | 8 1/4 | 1 | 9 9/16 | 8 7/16 | 7/8 | 1/2 x 2 | 9 3/8 | 15.2 |

| 14 | 2490 | 2220 | 9 | 1 1/8 | 10 5/8 | 9 1/4 | 7/8 | 1/2 x 2 1/2 | 10 3/8 | 20.5 |

| 16 | 2490 | 2220 | 10 | 1 1/8 | 11 5/8 | 10 1/4 | 7/8 | 1/2 x 2 1/2 | 11 3/8 | 22.3 |

| 18 | 3060 | 2730 | 11 1/2 | 1 1/4 | 13 | 11 5/8 | 1 | 5/8 x 2 1/2 | 12 7/8 | 31.6 |

| 20 | 3060 | 2730 | 12 1/2 | 1 3/8 | 14 1/8 | 12 3/4 | 1 1/8 | 5/8 x 2 1/2 | 13 7/8 | 35.8 |

| 24 | 3060 | 2730 | 15 | 1 5/8 | 16 7/8 | 15 1/4 | 1 1/4 | 5/8 x 3 | 16 5/8 | 53.1 |

| 30 | 3500 | 3360 | 18 1/4 | 2 | 21 1/4 | 19 | 1 3/4 | 3/4 x 4 | 20 5/8 | 113.9 |

| 36 | 4000 | 3570 | 22 1/2 | 2 1/2 | 25 1/2 | 23 | 2 | 1 x 5 | 25 | 219.0 |

Fig. 60: Heavy Two Bolt Clamp

SIZE RANGE: 3 inches thru 36 inches

MATERIAL: Carbon steel

FINISH: Black or galvanized; furnished black unless otherwise specified.

SERVICE: Recommended for suspension of cold or hot pipe lines with heavy load having little or no insulation.

MAX. TEMP.: 750°F

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD, lbs. | B | C | D | E | F | STOCK SIZE | H | K | APPROX. WEIGHT (lbs. per each) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 650° F | @ 750° F | G | |||||||||

| 3 | 3370 | 3005 | 2 15/16 | 1 | 4 | 3 1/8 | 3/4 | 5/16 x 2 | 3 13/16 | 5/8 | 3.60 |

| 3 1/2 | 3370 | 3005 | 3 1/4 | 1 | 4 1/4 | 3 3/8 | 3/4 | 5/16 x 2 | 3 13/16 | 5/8 | 3.90 |

| 4 | 3515 | 3135 | 3 9/16 | 1 | 4 7/8 | 3 3/4 | 7/8 | 3/8 x 2 | 4 11/16 | 5/8 | 5.50 |

| 5 | 3515 | 3135 | 4 1/8 | 1 | 5 1/2 | 4 3/8 | 7/8 | 3/8 x 2 | 5 1/4 | 5/8 | 6.30 |

| 6 | 4865 | 4340 | 5 | 1 1/8 | 6 5/8 | 5 1/4 | 1 | 1/2 x 2 1/2 | 6 3/8 | 7/8 | 11.70 |

| 8 | 4865 | 4340 | 6 1/8 | 1 1/8 | 7 5/8 | 6 1/4 | 1 | 1/2 x 2 1/2 | 7 1/2 | 7/8 | 13.90 |

| 10 | 6010 | 5360 | 7 9/16 | 1 1/4 | 9 1/16 | 7 11/16 | 1 1/4 | 5/8 x 2 1/2 | 8 15/16 | 7/8 | 22.30 |

| 12 | 8675 | 7740 | 9 | 1 5/8 | 10 7/8 | 9 1/4 | 1 1/2 | 3/4 x 3 | 10 5/8 | 7/8 | 38.10 |

| 14 | 9120 | 8135 | 9 3/4 | 1 5/8 | 11 7/8 | 10 | 1 1/2 | 3/4 x 4 | 11 5/8 | 7/8 | 46.80 |

| 16 | 9120 | 8135 | 10 3/4 | 1 5/8 | 12 7/8 | 11 | 1 1/2 | 3/4 x 4 | 12 5/8 | 7/8 | 51.40 |

| 18 | 13800 | 12305 | 14 1/2 | 3 | 17 1/4 | 14 1/2 | 2 | 3/4 x 6 | 17 1/4 | 3 | 130.10 |

| 20 | 15300 | 13645 | 16 | 3 | 18 3/4 | 16 | 2 | 1 x 5 | 18 3/4 | 3 | 163.60 |

| 24 | 16300 | 14535 | 18 1/2 | 3 1/4 | 21 1/2 | 18 1/2 | 2 1/4 | 1 x 6 | 21 1/2 | 3 1/4 | 215.00 |

| 28 | 18000 | 16055 | 20 1/2 | 3 1/4 | 23 1/2 | 20 1/2 | 2 1/4 | 1 x 8 | 23 1/2 | 3 1/4 | 303.00 |

| 30 | 20500 | 18285 | 22 1/2 | 3 1/2 | 26 | 22 1/2 | 2 1/2 | 1 1/4 x 7 | 26 | 3 1/2 | 365.40 |

| 32 | 23750 | 21180 | 23 1/2 | 3 1/2 | 27 | 23 1/2 | 2 1/2 | 1 1/4 x 8 | 27 | 3 1/2 | 432.00 |

| 34 | 25000 | 22295 | 25 | 3 1/2 | 28 1/2 | 25 | 2 1/2 | 1 1/2 x 8 | 28 1/2 | 3 1/2 | 534.00 |

| 36 | 28000 | 24975 | 26 1/2 | 3 1/2 | 30 1/4 | 26 1/2 | 2 3/4 | 1 1/2 x 8 | 33 3/4 | 3 1/2 | 575.00 |

Fig. 70: Light Three Bolt Pipe Clamp

SIZE RANGE: 1/2 inch thru 36 inches

MATERIAL: Carbon steel

FINISH: Black or galvanized; furnished black unless otherwise specified.

SERVICE: Recommended for suspension of cold or hot pipe lines requiring little insulation or insulation up to 4 inches

MAX. TEMP.: 750°F

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD, lbs. | B | C | D | E | F | G | H | APPROX. WEIGHT | |

|---|---|---|---|---|---|---|---|---|---|---|

| @ 650° F | @ 750° F | lbs. per each | ||||||||

| 1/2 | 950 | 850 | 15/16 | 5/16 | 2 7/8 | 2 7/16 | 3/8 | 3/16 x 1 | 1 3/8 | 0.66 |

| 3/4 | 950 | 850 | 15/16 | 5/8 | 2 7/8 | 2 7/16 | 3/8 | 3/16 x 1 | 1 3/8 | 0.70 |

| 1 | 950 | 850 | 1 1/16 | 5/8 | 3 | 2 9/16 | 3/8 | 3/16 x 1 | 1 1/2 | 0.76 |

| 1 1/4 | 950 | 850 | 1 1/4 | 5/8 | 3 1/8 | 2 11/16 | 3/8 | 3/16 x 1 | 1 11/16 | 0.81 |

| 1 1/2 | 1545 | 1380 | 1 13/16 | 1 1/16 | 4 7/8 | 4 1/8 | 5/8 | 1/4 x 1 1/4 | 2 3/8 | 2.30 |

| 2 | 1545 | 1380 | 2 1/8 | 1 1/16 | 5 7/8 | 5 1/8 | 5/8 | 1/4 x 1 1/4 | 2 11/16 | 2.60 |

| 2 1/2 | 1545 | 1380 | 2 5/16 | 1 1/16 | 6 1/8 | 5 3/8 | 5/8 | 1/4 x 1 1/4 | 2 15/16 | 2.70 |

| 3 | 1545 | 1380 | 2 3/4 | 1 1/16 | 6 11/16 | 5 15/16 | 5/8 | 1/4 x 1 1/4 | 3 1/2 | 3.00 |

| 4 | 2500 | 2230 | 3 3/8 | 1 1/16 | 7 5/8 | 6 1/2 | 3/4 | 5/16 x 2 | 4 1/2 | 6.70 |

| 5 | 2500 | 2230 | 3 15/16 | 1 1/16 | 8 1/8 | 7 | 3/4 | 5/16 x 2 | 5 | 7.00 |

| 6 | 2865 | 2555 | 4 3/4 | 1 7/16 | 9 11/16 | 8 9/16 | 7/8 | 3/8 x 2 1/2 | 6 1/8 | 11.50 |

| 8 | 2865 | 2555 | 5 3/4 | 1 7/16 | 10 11/16 | 9 9/16 | 7/8 | 3/8 x 2 1/2 | 7 1/8 | 13.20 |

| 10 | 3240 | 2890 | 6 7/8 | 1 7/16 | 12 | 10 5/8 | 1 | 1/2 x 2 1/2 | 8 1/4 | 19.80 |

| 12 | 3240 | 2890 | 7 7/8 | 1 7/16 | 13 | 11 5/8 | 1 | 1/2 x 2 1/2 | 9 1/4 | 22.30 |

| 14 | 4300 | 3835 | 9 1/16 | 2 | 14 5/16 | 12 11/16 | 1 1/4 | 5/8 x 3 | 10 11/16 | 37.70 |

| 16 | 4300 | 3835 | 10 1/16 | 2 | 15 5/16 | 13 11/16 | 1 1/4 | 5/8 x 3 | 11 11/16 | 41.40 |

| 18 | 4300 | 3835 | 11 1/16 | 2 | 16 5/16 | 14 11/16 | 1 1/4 | 5/8 x 3 | 12 11/16 | 44.90 |

| 20 | 5490 | 4900 | 12 3/8 | 2 | 17 5/8 | 15 7/8 | 1 1/2 | 3/4 x 3 | 14 | 57.30 |

| 24 | 4500 | 4015 | 14 3/8 | 2 | 19 5/8 | 17 7/8 | 1 1/2 | 3/4 x 3 | 16 | 65.90 |

| 28 | 6000 | 5340 | 17 1/2 | 2 1/4 | 24 1/4 | 21 3/4 | 1 1/2 | 3/4 x 4 | 20 | 112.30 |

| 30 | 7500 | 6675 | 18 1/2 | 2 1/2 | 26 1/8 | 23 3/8 | 1 1/2 | 3/4 x 5 | 21 1/4 | 150.00 |

| 36 | 10500 | 9345 | 22 1/2 | 3 | 32 1/4 | 28 3/4 | 1 3/4 | 1 x 5 | 26 | 257.50 |

Fig. 70A: Alloy Three Bolt Pipe Clamp

SIZE RANGE: 1/2 inch thru 36 inches

MATERIAL: Chrome molybdenum steel (ASTM A387)

FINISH: Black

SERVICE: Recommended for suspension of hot pipe lines requiring up to 4″ of insulation.

MAX. TEMP.: 1050°F

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD, lbs. | B | C | D | E | F | G | H | APPROX. WEIGHT (lbs. per each) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 750° F | @ 1000° F | @ 1050° F | |||||||||

| 1/2 | 860 | 610 | 455 | 15/16 | 5/16 | 2 7/8 | 2 7/16 | 3/8 | 3/16 x 1 | 1 3/8 | 0.66 |

| 3/4 | 860 | 610 | 455 | 15/16 | 5/8 | 2 7/8 | 2 7/16 | 3/8 | 3/16 x 1 | 1 3/8 | 0.70 |

| 1 | 860 | 610 | 455 | 1 1/16 | 5/8 | 3 | 2 9/16 | 3/8 | 3/16 x 1 | 1 1/2 | 0.76 |

| 1 1/4 | 860 | 610 | 455 | 1 1/4 | 5/8 | 3 1/8 | 2 11/16 | 3/8 | 3/16 x 1 | 1 11/16 | 0.81 |

| 1 1/2 | 1410 | 1000 | 745 | 1 13/16 | 1 1/16 | 4 7/8 | 4 1/8 | 5/8 | 1/4 x 1 1/4 | 2 3/8 | 2.30 |

| 2 | 1410 | 1000 | 745 | 2 1/8 | 1 1/16 | 5 7/8 | 5 1/8 | 5/8 | 1/4 x 1 1/4 | 2 11/16 | 2.60 |

| 2 1/2 | 1410 | 1000 | 745 | 2 5/16 | 1 1/16 | 6 1/8 | 5 3/8 | 5/8 | 1/4 x 1 1/4 | 2 15/16 | 2.70 |

| 3 | 1410 | 1000 | 745 | 2 3/4 | 1 1/16 | 6 11/16 | 5 15/16 | 5/8 | 1/4 x 1 1/4 | 3 1/2 | 3.00 |

| 4 | 2290 | 1625 | 1200 | 3 3/8 | 1 1/16 | 7 5/8 | 6 1/2 | 3/4 | 5/16 x 2 | 4 1/2 | 6.70 |

| 5 | 2290 | 1625 | 1200 | 3 15/16 | 1 1/16 | 8 1/8 | 7 | 3/4 | 5/16 x 2 | 5 | 7.00 |

| 6 | 2620 | 1860 | 1380 | 4 3/4 | 1 7/16 | 9 11/16 | 8 9/16 | 7/8 | 3/8 x 2 1/2 | 6 1/8 | 11.50 |

| 8 | 2620 | 1860 | 1380 | 5 3/4 | 1 7/16 | 10 11/16 | 9 9/16 | 7/8 | 3/8 x 2 1/2 | 7 1/8 | 13.20 |

| 10 | 2970 | 2100 | 1565 | 6 7/8 | 1 7/16 | 12 | 10 7/16 | 1 | 1/2 x 2 1/2 | 8 1/4 | 19.80 |

| 12 | 2970 | 2095 | 1555 | 7 7/8 | 1 7/16 | 13 | 11 7/16 | 1 | 1/2 x 2 1/2 | 9 1/4 | 22.30 |

| 14 | 3915 | 2795 | 2060 | 9 1/16 | 2 | 14 5/16 | 12 11/16 | 1 1/4 | 5/8 x 3 | 10 11/16 | 37.70 |

| 16 | 3915 | 2795 | 2060 | 10 1/16 | 2 | 15 5/16 | 13 11/16 | 1 1/4 | 5/8 x 3 | 11 11/16 | 41.40 |

| 18 | 3915 | 2795 | 2060 | 11 1/16 | 2 | 16 5/16 | 14 11/16 | 1 1/4 | 5/8 x 3 | 12 11/16 | 44.90 |

| 20 | 4995 | 3550 | 2635 | 12 3/8 | 2 | 17 5/8 | 15 7/8 | 1 1/2 | 3/4 x 3 | 14 | 57.30 |

| 24 | 4995 | 3550 | 2635 | 14 3/8 | 2 | 19 5/8 | 17 7/8 | 1 1/2 | 3/4 x 3 | 16 | 65.90 |

| 28 | 5475 | 3890 | 2900 | 17 1/2 | 2 1/4 | 24 1/4 | 21 3/4 | 1 1/2 | 3/4 x 4 | 20 | 112.30 |

| 30 | 6850 | 4860 | 3630 | 18 1/2 | 2 1/2 | 26 1/8 | 23 3/8 | 1 1/2 | 3/4 x 5 | 21 1/4 | 150.00 |

| 36 | 9580 | 6800 | 5070 | 22 1/2 | 3 | 32 1/4 | 28 3/4 | 1 3/4 | 1 x 5 | 26 | 257.50 |

Fig. 80: Heavy Three Bolt Pipe Clamp

SIZE RANGE: 1/2 inch thru 36 inches

MATERIAL: Carbon steel

FINISH: Black or galvanized; furnished black unless otherwise specified.

SERVICE: Recommended for suspension of cold pipe lines or hot lines where little or no insulation is required.

MAX. TEMP.: 750°F

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD, lbs. | B | C | D | E | F | G | H | APPROX. WEIGHT lbs. per each | |

|---|---|---|---|---|---|---|---|---|---|---|

| @ 650° F | @ 750° F | |||||||||

| 1 1/2 | 2710 | 2420 | 2 1/8 | 1 | 5 13/16 | 5 | 3/4 | 3/8 x 2 | 3 1/8 | 5.5 |

| 2 | 2710 | 2420 | 3 | 1 | 6 1/16 | 5 1/16 | 3/4 | 3/8 x 2 | 4 | 5.7 |

| 3 | 2710 | 2420 | 3 5/8 | 1 1/2 | 8 | 6 1/2 | 3/4 | 3/8 x 2 | 5 1/8 | 7.5 |

| 4 | 3500 | 3125 | 4 1/2 | 1 3/4 | 9 | 7 | 7/8 | 3/8 x 2 1/2 | 6 1/2 | 10.7 |

| 6 | 3500 | 3125 | 4 3/4 | 1 3/4 | 10 3/16 | 8 15/16 | 1 | 3/8 x 2 1/2 | 6 | 12.0 |

| 8 | 4800 | 4285 | 6 | 2 | 11 3/8 | 10 1/8 | 1 1/8 | 1/2 x 2 1/2 | 7 1/4 | 18.5 |

| 10 | 5500 | 4910 | 7 1/4 | 2 1/4 | 13 1/8 | 11 3/8 | 1 1/4 | 1/2 x 3 1/2 | 9 | 30.3 |

| 12 | 7000 | 6250 | 8 5/8 | 2 1/2 | 14 5/16 | 12 9/16 | 1 3/8 | 5/8 x 3 1/2 | 10 3/8 | 42.0 |

| 14 | 9500 | 8485 | 9 5/8 | 2 1/2 | 15 1/2 | 13 1/2 | 1 1/2 | 3/4 x 4 | 11 5/8 | 60.0 |

| 16 | 10000 | 8930 | 10 7/8 | 3 | 17 1/8 | 14 7/8 | 1 3/4 | 3/4 x 4 1/2 | 13 1/8 | 80.0 |

| 18 | 13800 | 12325 | 12 1/2 | 3 1/2 | 18 1/4 | 16 1/4 | 2 | 1 x 4 | 14 1/2 | 115.0 |

| 20 | 15300 | 13665 | 13 1/2 | 3 1/2 | 19 3/4 | 17 1/4 | 2 | 1 x 5 | 16 | 140.0 |

| 24 | 16300 | 14555 | 15 1/2 | 3 1/2 | 22 5/16 | 19 5/16 | 2 | 1 x 6 | 18 1/2 | 190.0 |

| 28 | 18000 | 16055 | 18 7/8 | 4 | 31 3/4 | 27 1/4 | 2 1/4 | 1 x 7 | 23 3/8 | 354.0 |

| 30 | 20500 | 18285 | 19 7/8 | 4 1/4 | 32 3/4 | 28 1/4 | 2 1/4 | 1 x 8 | 24 3/8 | 406.0 |

| 36 | 28000 | 24975 | 24 5/8 | 4 1/2 | 40 1/4 | 34 3/4 | 2 3/4 | 1 1/2 x 8 | 30 1/8 | 678.0 |

Fig. 90: Riser Clamp

SIZE RANGE: 1/2″ thru 24″

MATERIAL: Carbon steel

FINISH: Black or galvanized; furnished black unless otherwise specified.

SERVICE: For support and steadying of steel pipe risers either insulated or bare, cast iron pipe, or conduit.

MAX. TEMP.: 650°F

ORDERING: Specify figure number, pipe size, description and finish.

| PIPE SIZE | MAX. RECOM. LOAD | APPROX. WEIGHT | LENGTH | STOCK SIZE | BOLT SIZE |

|---|---|---|---|---|---|

| lbs. | lbs. per 100 | A | |||

| 1/2 | 255 | 123 | 9 3/8 | 3/16 x 1 1/4 | 3/8 x 1 1/2 |

| 3/4 | 255 | 136 | 9 3/8 | 3/16 x 1 1/4 | 3/8 x 1 1/2 |

| 1 | 255 | 138 | 9 5/8 | 3/16 x 1 1/4 | 3/8 x 1 1/2 |

| 1 1/4 | 390 | 195 | 10 | 1/4 x 1 1/4 | 3/8 x 1 1/2 |

| 1 1/2 | 390 | 201 | 10 3/8 | 1/4 x 1 1/4 | 3/8 x 1 1/2 |

| 2 | 390 | 217 | 10 3/4 | 1/4 x 1 1/4 | 7/16 x 2 |

| 2 1/2 | 390 | 229 | 11 1/4 | 1/4 x 1 1/4 | 7/16 x 2 |

| 3 | 530 | 250 | 12 | 1/4 x 1 1/4 | 7/16 x 2 |

| 3 1/2 | 670 | 330 | 13 | 1/4 x 1 1/2 | 1/2 x 2 |

| 4 | 810 | 342 | 13 1/2 | 1/4 x 1 1/2 | 1/2 x 2 |

| 5 | 1160 | 493 | 14 1/2 | 1/4 x 2 | 1/2 x 2 |

| 6 | 1570 | 526 | 15 1/2 | 1/4 x 2 | 1/2 x 2 |

| 8 | 2500 | 986 | 18 1/2 | 3/8 x 2 | 5/8 x 2 1/2 |

| 10 | 2500 | 1112 | 20 3/4 | 3/8 x 2 | 5/8 x 2 1/2 |

| 12 | 2700 | 1662 | 22 3/4 | 1/2 x 2 | 5/8 x 3 |

| 14 | 2700 | 1925 | 24 | 1/2 x 2 | 5/8 x 3 |

| 16 | 2900 | 3250 | 26 | 5/8 x 2 1/2 | 3/4 x 3 1/2 |

| 18 | 2900 | 3375 | 28 | 5/8 x 2 1/2 | 3/4 x 3 1/2 |

| 20 | 2900 | 3500 | 30 | 5/8 x 2 1/2 | 3/4 x 3 1/2 |

| 24 | 3200 | 5070 | 36 | 5/8 x 3 | 7/8 x 3 1/2 |

Fig. 190: Fabricated Riser Clamp

SERVICE:

In situations where the use of a welded lug attachment would create an undesirable crushing effect on the pipe wall, this clamp can transfer the load from the pipe wall to the riser clamp by means of hold-down lugs welded to the pipe.

Clamps may be furnished in either Carbon or Alloy steel with bolting to suit, using an allowable stress of 10,000 PSI. Temperature correction factors listed in “CHART A” are based on allowable stresses listed in MSS-SP-58.

METHODS OF SELECTION:

1. Determine total load to be supported and service temperature of the piping system.

2. Refer to “CHART A (table below)” and determine the temperature correction factor for the clamp material being used.

3. Multiply total load by the correction factor to obtain a corrected load.

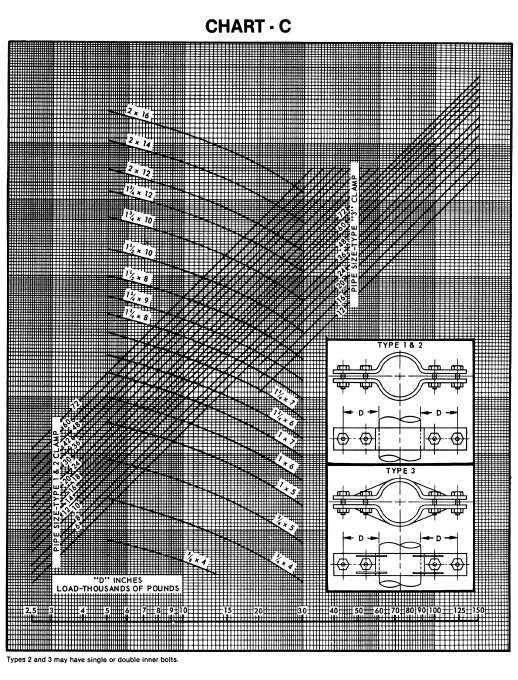

4. Refer to “CHART C (below)” and locate the point determined by the intersection of the total load co-ordinate and the pipe size curve. Project this point horizontally until it intersects with the “D” dimension coordinate. Directly above this point is the required stock size.

5. The bolt diameter is obtained by using the uncorrected total load and referring to “CHART B (below)”.

ORDERING: Specify pipe outside diameter, total load, design temperature, material and dimension “D” or center to center of hanger rods.

NOTE: Pipe clamp can be fabricated to any specified material.

| CHART A - STRESS-TEMPERATURE CORRECTION FACTORS | |||||||||||||

| Material Specification | DESIGN TEMPERATURE °F | ||||||||||||

| ASTM | GRADE | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 |

| A 36 | - | 0.8 | 0.83 | 0.89 | 1.06 | - | - | - | - | - | - | - | - |

| A . 387 | 11 | 0.66 | 0.66 | 0.66 | 0.66 | 0.69 | 0.76 | 0.91 | 1.53 | - | - | - | - |

| A . 387 | 22 | 0.66 | 0.66 | 0.66 | 0.66 | 0.69 | 0.76 | 0.91 | 1.28 | 1.72 | 2.38 | - | - |

| A . 240 | 304 | 0.94 | 0.95 | 0.96 | 0.97 | 0.99 | 1 | 1.02 | 1.02 | 1.11 | 1.21 | 1.45 | 1.81 |

| CHART B – CLAMP SPACING AND BOLT SIZES | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uncorrected Total Load lb. | 3,400 | 4,700 | 6,200 | 8,000 | 10,000 | 12,000 | 16,000 | 19,000 | 25,000 | 32,000 | 40,000 | 55,000 | 67,000 | 82,000 | 96,000 | 118,000 | 135,000 | 154,000 |

| BOLT – B | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 | 1 3/4 | 2 | 2 1/4 | 2 1/2 | 2 3/4 | 3 | 3 1/4 | 3 1/2 | 3 3/4 | 4 |

| BOLT – C | – | – | – | 3/4 | 7/8 | 1 | 1 | 1 1/8 | 1 3/8 | 1 1/2 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 3/4 | 3 | 3 |

| SPACE – S | 7/8 | 1 | 1 1/4 | 1 1/2 | 1 1/2 | 1 3/4 | 1 7/8 | 2 1/4 | 2 1/4 | 2 1/2 | 3 | 3 1/4 | 3 1/2 | 4 | 4 | 4 1/4 | 4 1/2 | 4 3/4 |

PT&P’s entire range of Pipe Clamps can be integrated with TPI Clips as well as vibration pads.

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});