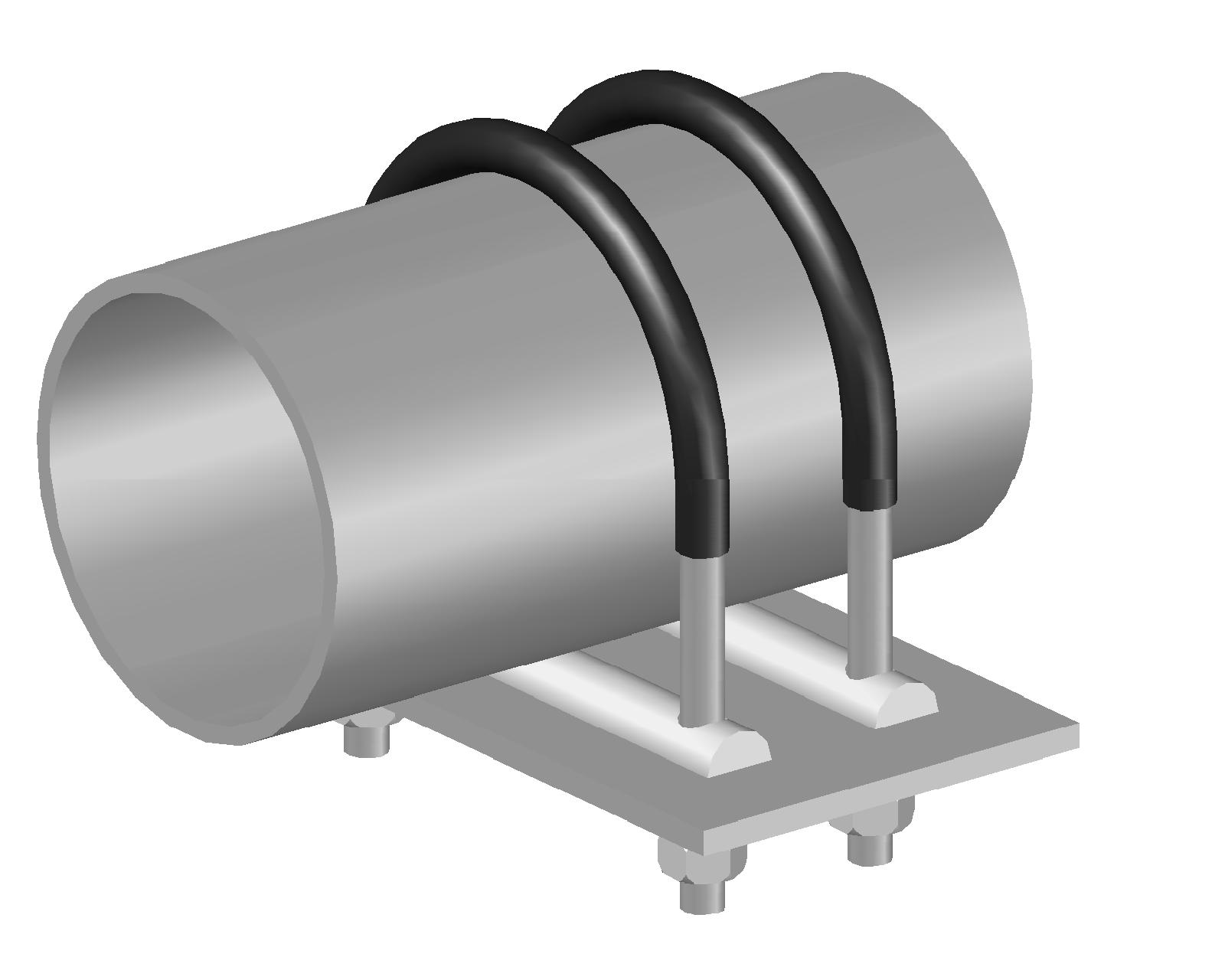

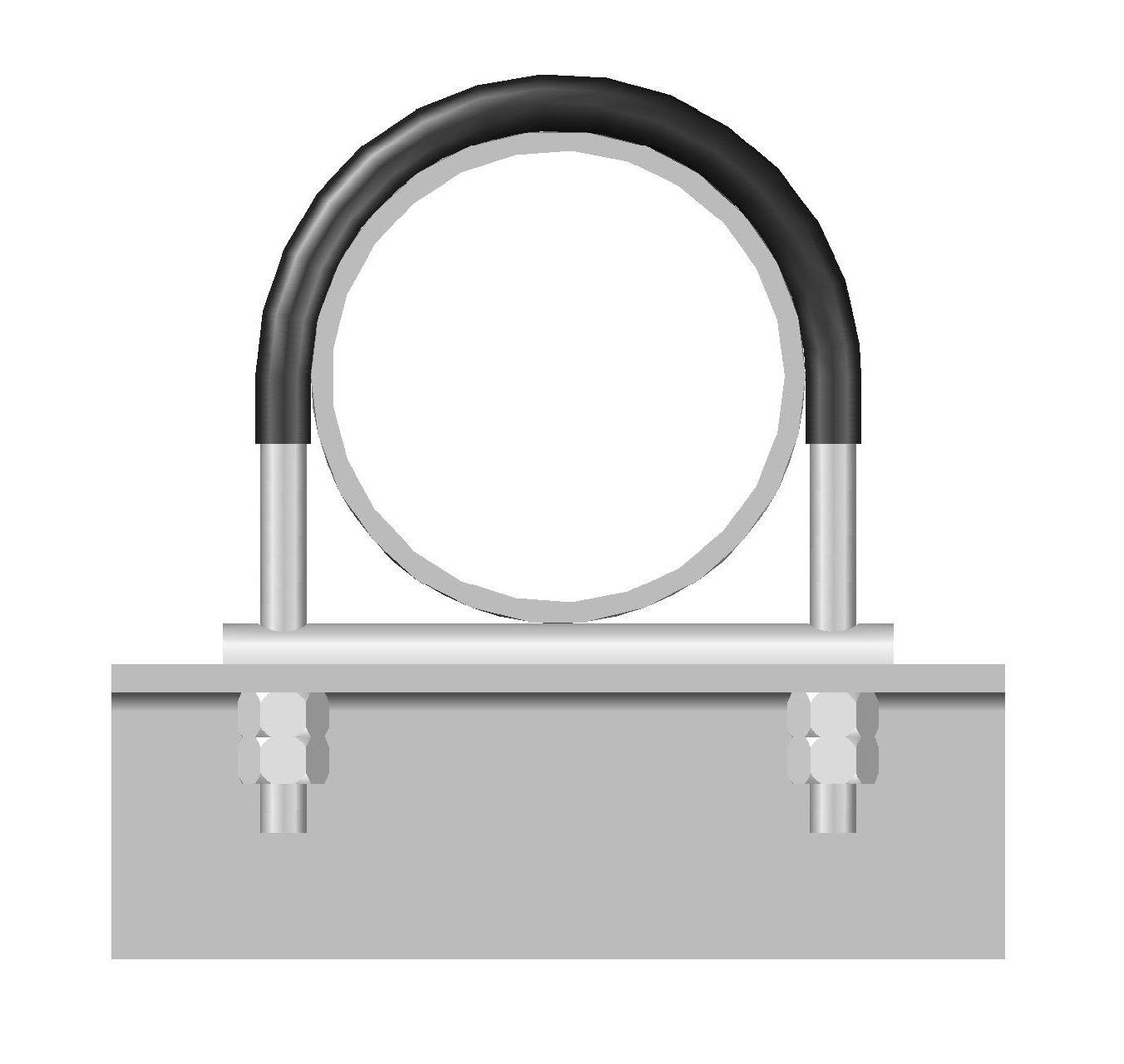

U-Bolts

U-bolts are a u-shaped rod with threaded ends, that fits around a pipe and is attached to a supporting member.

Ammonia Plant

Chemical Plant

Clean Fuels

Commercial

Electric Plant

Energy Facility

Ethylene Plant

LLDPE Chemical Plant

LNG Plant

MTBE Plant

Natural Gas Combined Cycle Facility

Natural Gas Processing & Separation

Oil Refinery

Oil Sand Mine

Paper Manufacturer

See All

U-bolts can be utilized as pipe guides when the horizontal forces are relatively small (usually 10% or less) compared with ...Continue Reading

Linked eye rods are primarily used in rod hanger assemblies where lateralor axial pipe movement must be accommodated. Linked Eye ...Continue Reading

An eye rod is a hanger rod where the lower section consists of either a formed portion (to form an ...Continue Reading

Long tangent refers to the length of the straight leg portion of the u-bolt which specifies the height of the ...Continue Reading

In order to specify a u-bolt for pipes, you must provide the diameter of the pipe, the material, the tangent ...Continue Reading

When installing clevises, first you should disengage the pin connection of the clevis. Then align the clevis pin holes with ...Continue Reading

More FAQs…

GENERAL DIMENSIONS & SPECIFICATIONS

- U-Bolts Information

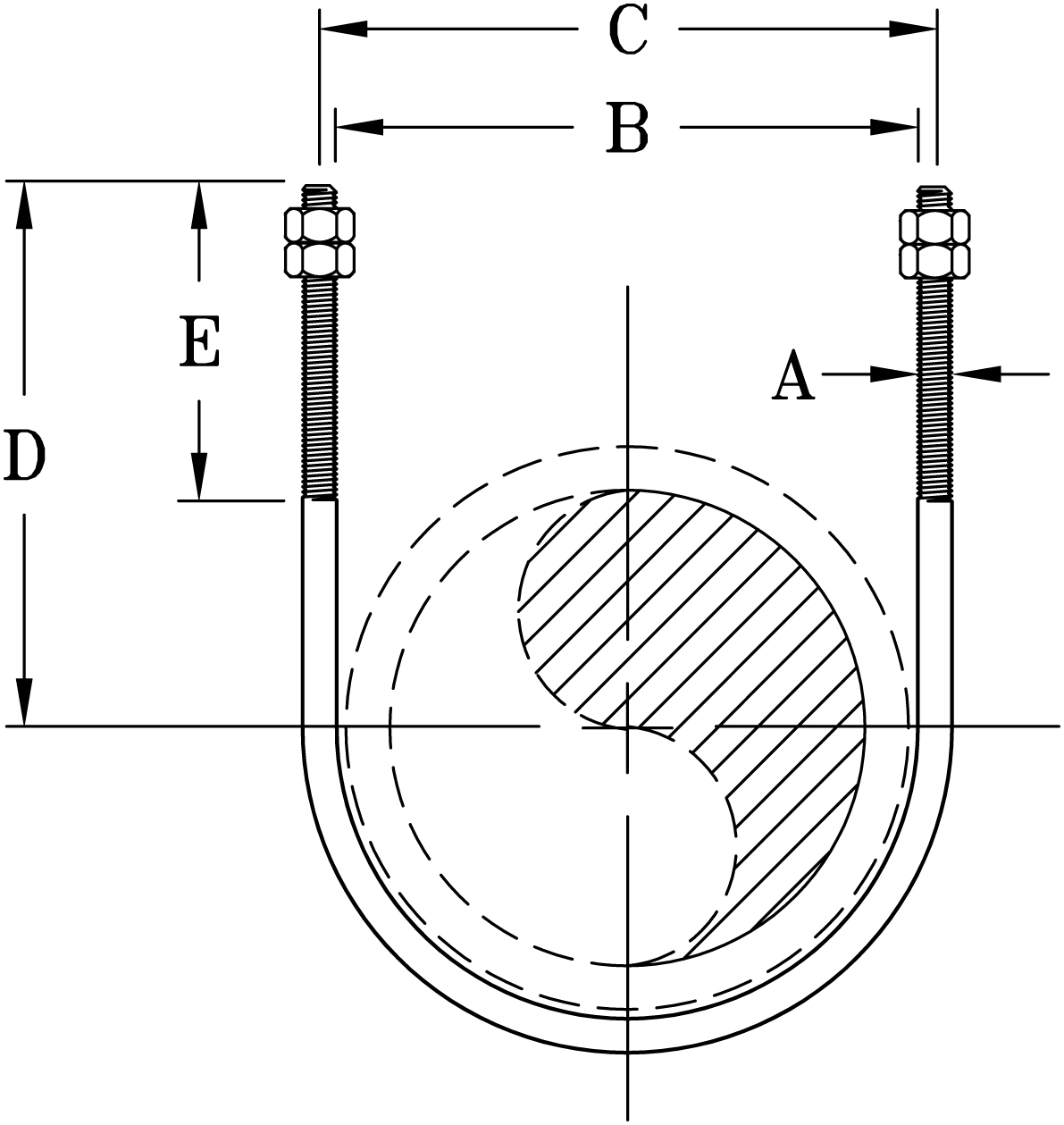

- Fig. 100: Tangent U-Bolt

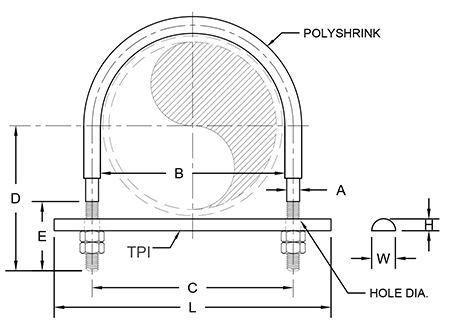

- Fig. 100-TPI: Long Tangent U-Bolt with Thermal Plastic Isolator (TPI) & Isolator Coating

- Fig. 100-TPI-VP: Long Tangent U-Bolt with TPI & Vibration Pad "Super U-Bolt"

- Request a Quote

The humble U-Bolt has been a staple of Operating Plants for decades so we know it is an unusual time to be launching U-Bolt innovation. However, PT&P has seen many customers struggle with issues around U-Bolts. In fact, one of the challenges is that the U-Bolt is used so often that it is difficult to get the right configuration. Some of the challenges with U-Bolts include:

Contact Corrosion – the interface of non-insulated steel piping with a U-Bolt is subject to accelerated corrosion at the point of contact. This is due to crevice corrosion which occurs due to the crevice formed next to the contact between the Pipe and base of the U-Bolt. *View more on contact corrosion

Thermal Growth Issues – PT&P has seen many U-Bolts that were not designed to accommodate the axial movement associated with thermal growth.

Corrosion of U-Bolt – certain environments can lead to accelerated corrosion of U-Bolts which are made with traditional galvanized steel.

Sizing – some customers struggle with unusual sizing requirements

Coating of U – some customers struggle with getting the right coating on the U portion of the U-Bolt

The Super U-Bolt

PT&P’s Super U-Bolt provides customers with solutions to these issues by providing the broadest range of options:

Vibration Energy Absorption – PT&P offers customers the option to add a Vibration Pad which converts some of the mechanical energy of Vibration to heat. A traditional U-Bolt just stiffens the piping system by causing it to resist movement. However, this does not remove the vibration energy from the system and it continues down the piping system. Vibration pads offer energy absorption of up to 80% of the mechanical energy being converted to heat! *View more vibration solutions

Eliminate Contact Corrosion with TPI – PT&P’s half-round thermoplastics limit the touchpoint between the piping and U-Bolt.

Material Customization – Customers can specify a broad range of materials including various grades of stainless and even Super Alloys.

Custom Finish on U – PT&P offers a standard plasticized finish. Custom finishes such as Neoprene can also be specified to suit particular applications.

Custom Sizes – PT&P’s unique mass customization manufacturing operation allows us to customize sizes far more easily than any other provider. *View more on customization

*View more on manufacturing

Allowance for Axial Movement – If axial movement is desired, PT&P can provide a configuration that offers a low coefficient of friction. Options include PTFE coating or TPI.

Types of U-Bolts:

Fig. 100 – Tangent U-Bolt

Fig. 100-TPI: Long Tangent U-Bolt with Thermal Plastic Isolator & & Isolator Coating

Fig. 100-TPI-VP: Long Tangent U-Bolt with TPI & Vibration Pad “Super U-Bolt”

Fig. 100: Tangent U-Bolt

MATERIAL: Carbon steel

FINISH: Black. Galvanized upon request.

ORDERING: Specify figure number, pipe size, description, and finish, if other than black.

NOTE:

• U-bolts are furnished with four hexagon nuts or are furnished with two hexagon nuts.

• Special U-bolts with longer tangents and threads and special materials can be furnished as specified.

| PIPE SIZE | MAX. RECOM. LOAD (lb.) | A | B | C | D | E | WEIGHT per 100 |

|---|---|---|---|---|---|---|---|

| 1/2 | 580 | 1/4 | 7/8 | 1 1/8 | 2 1/2 | 2 1/2 | 12 |

| 3/4 | 580 | 1/4 | 1 1/8 | 1 3/8 | 2 5/8 | 2 1/2 | 13 |

| 1 | 580 | 1/4 | 1 3/8 | 1 5/8 | 2 3/4 | 2 1/2 | 14 |

| 1 1/4 | 1460 | 3/8 | 1 3/4 | 2 1/8 | 2 7/8 | 2 1/2 | 38 |

| 1 1/2 | 1460 | 3/8 | 2 | 2 3/8 | 3 | 2 1/2 | 39 |

| 2 | 1460 | 3/8 | 2 1/2 | 2 7/8 | 3 1/4 | 2 1/2 | 42 |

| 2 1/2 | 2700 | 1/2 | 3 | 3 1/2 | 3 3/4 | 3 | 90 |

| 3 | 2700 | 1/2 | 3 5/8 | 4 1/8 | 4 | 3 | 99 |

| 3 1/2 | 2700 | 1/2 | 4 1/8 | 4 5/8 | 4 1/4 | 3 | 109 |

| 4 | 2700 | 1/2 | 4 5/8 | 5 1/8 | 4 1/2 | 3 | 115 |

| 5 | 2700 | 1/2 | 5 5/8 | 6 1/8 | 5 | 3 | 128 |

| 6 | 4320 | 5/8 | 6 3/4 | 7 3/8 | 6 1/8 | 3 3/4 | 239 |

| 8 | 4320 | 5/8 | 8 3/4 | 9 3/8 | 7 1/8 | 3 3/4 | 283 |

| 10 | 6460 | 3/4 | 10 7/8 | 11 5/8 | 8 3/8 | 4 | 479 |

| 12 | 9960 | 7/8 | 12 7/8 | 13 3/4 | 9 5/8 | 4 1/4 | 764 |

| 14 | 9960 | 7/8 | 14 1/8 | 15 | 10 1/4 | 4 1/4 | 820 |

| 16 | 9960 | 7/8 | 16 1/8 | 17 | 11 1/4 | 4 1/4 | 870 |

| 18 | 11800 | 1 | 18 1/8 | 19 1/8 | 12 5/8 | 4 3/4 | 1350 |

| 20 | 11800 | 1 | 20 1/8 | 21 1/8 | 13 5/8 | 4 3/4 | 1460 |

| 24 | 11800 | 1 | 24 1/8 | 25 1/8 | 15 5/8 | 4 3/4 | 1710 |

| 30 | 11800 | 1 | 30 1/8 | 31 1/8 | 18 5/8 | 4 3/4 | 1920 |

| 36 | 11800 | 1 | 36 1/8 | 37 1/8 | 21 5/8 | 4 3/4 | 2326 |

Fig. 100-TPI: Long Tangent U-Bolt with Thermal Plastic Isolator (TPI) & Isolator Coating

MATERIAL: Carbon steel

FINISH: Black or Galvanized with Isolated Coating (furnished black unless otherwise specified.)

ORDERING: Specify figure number, pipe size, description and finish, operating temperature and any other special requirements

NOTE:

• U-bolts are furnished with four hexagon nuts, thermal plastic isolator (TPI), and isolator coating.

• Special U-bolts with longer tangents, threads and special material can be furnished as specified

• Thermal Plastic Isolator (TPI) color = white

• Maximum Service Temperature = 181°F

• Coefficient of friction = 0.25

• Compressive strength = 15,000 psi

• Higher temperature thermal plastic isolators (TPI) are available on request

• Isolator Coating: Tensile Strength = 2,100 psi

Learn more about Thermoplastic Isolators, visit the technical page: Thermoplastic Isolator (TPI) – Technical Information

|

NOMINAL PIPE SIZE |

MAX. RECOM. LOAD (lb.) | Rod Dia | B | C | D | E | TPI | |||

|---|---|---|---|---|---|---|---|---|---|---|

| L | Hole Dia | W | H | |||||||

| 1/2 | 580 | 1/4 | 1 | 1 7/16 | 3 1/2 | 3 1/2 | 2 1/2 | 3/8 | 3/4 | 5/16 |

| 3/4 | 580 | 1/4 | 1 3/16 | 1 5/8 | 3 5/8 | 3 1/2 | 3 | 3/8 | 3/4 | 5/16 |

| 1 | 580 | 1/4 | 1 1/2 | 1 15/16 | 3 3/4 | 3 1/2 | 3 | 3/8 | 3/4 | 5/16 |

| 1 1/4 | 1460 | 3/8 | 1 13/16 | 2 3/8 | 3 7/8 | 3 1/2 | 3 1/2 | 1/2 | 1 | 7/16 |

| 1 1/2 | 1460 | 3/8 | 2 1/16 | 2 5/8 | 4 | 3 1/2 | 4 | 1/2 | 1 | 7/16 |

| 2 | 1460 | 3/8 | 2 1/2 | 3 1/16 | 4 1/4 | 3 1/2 | 4 1/2 | 1/2 | 1 | 7/16 |

| 2 1/2 | 2700 | 1/2 | 3 | 3 11/16 | 4 3/4 | 4 | 5 | 5/8 | 1 | 7/16 |

| 3 | 2700 | 1/2 | 3 5/8 | 4 5/16 | 5 | 4 | 6 | 5/8 | 1 | 7/16 |

| 3 1/2 | 2700 | 1/2 | 4 1/8 | 4 13/16 | 5 1/4 | 4 | 7 | 5/8 | 1 | 7/16 |

| 4 | 2700 | 1/2 | 4 5/8 | 5 5/16 | 5 1/2 | 4 | 7 | 5/8 | 1 | 7/16 |

| 5 | 2700 | 1/2 | 5 5/8 | 6 5/16 | 6 | 4 | 8 | 5/8 | 1 | 7/16 |

| 6 | 4320 | 5/8 | 6 3/4 | 7 9/16 | 7 1/8 | 4 3/4 | 9 | 11/16 | 1 | 7/16 |

| 8 | 4320 | 5/8 | 8 3/4 | 9 9/16 | 8 1/8 | 4 3/4 | 11 | 11/16 | 1 | 7/16 |

| 10 | 6460 | 3/4 | 10 7/8 | 11 13/16 | 9 3/8 | 5 | 13 1/2 | 7/8 | 1 1/2 | 11/16 |

| 12 | 9960 | 7/8 | 12 7/8 | 13 15/16 | 10 5/8 | 5 1/4 | 16 | 1 | 1 1/2 | 11/16 |

| 14 | 9960 | 7/8 | 14 1/8 | 15 3/16 | 11 1/4 | 5 1/4 | 17 | 1 | 1 1/2 | 11/16 |

| 16 | 9960 | 7/8 | 16 1/8 | 17 3/16 | 12 1/4 | 5 1/4 | 19 | 1 | 1 1/2 | 11/16 |

| 18 | 11800 | 1 | 18 1/8 | 19 5/16 | 13 5/8 | 5 3/4 | 21 1/2 | 1 1/8 | 1 1/2 | 11/16 |

| 20 | 11800 | 1 | 20 1/8 | 21 5/16 | 14 5/8 | 5 3/4 | 23 1/2 | 1 1/8 | 1 1/2 | 11/16 |

| 24 | 11800 | 1 | 24 1/8 | 25 5/16 | 16 5/8 | 5 3/4 | 27 1/2 | 1 1/8 | 1 1/2 | 11/16 |

| 30 | 11800 | 1 | 30 1/8 | 31 5/16 | 19 5/8 | 5 3/4 | 33 1/2 | 1 1/8 | 1 1/2 | 11/16 |

| 36 | 11800 | 1 | 36 1/8 | 37 5/16 | 22 5/8 | 5 3/4 | 39 1/2 | 1 1/8 | 1 1/2 | 11/16 |

Fig. 100-TPI-VP: Long Tangent U-Bolt with TPI & Vibration Pad

Pictured below is a Super U-Bolt made of stainless steel (304) with a Vibration Pad and TPI added. We know of no other company that offers a U-Bolt with both vibration dampening and contact corrosion solutions.

Figure 1 – PT&P Super U-Bolt with TPI and Vibration Pad

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});