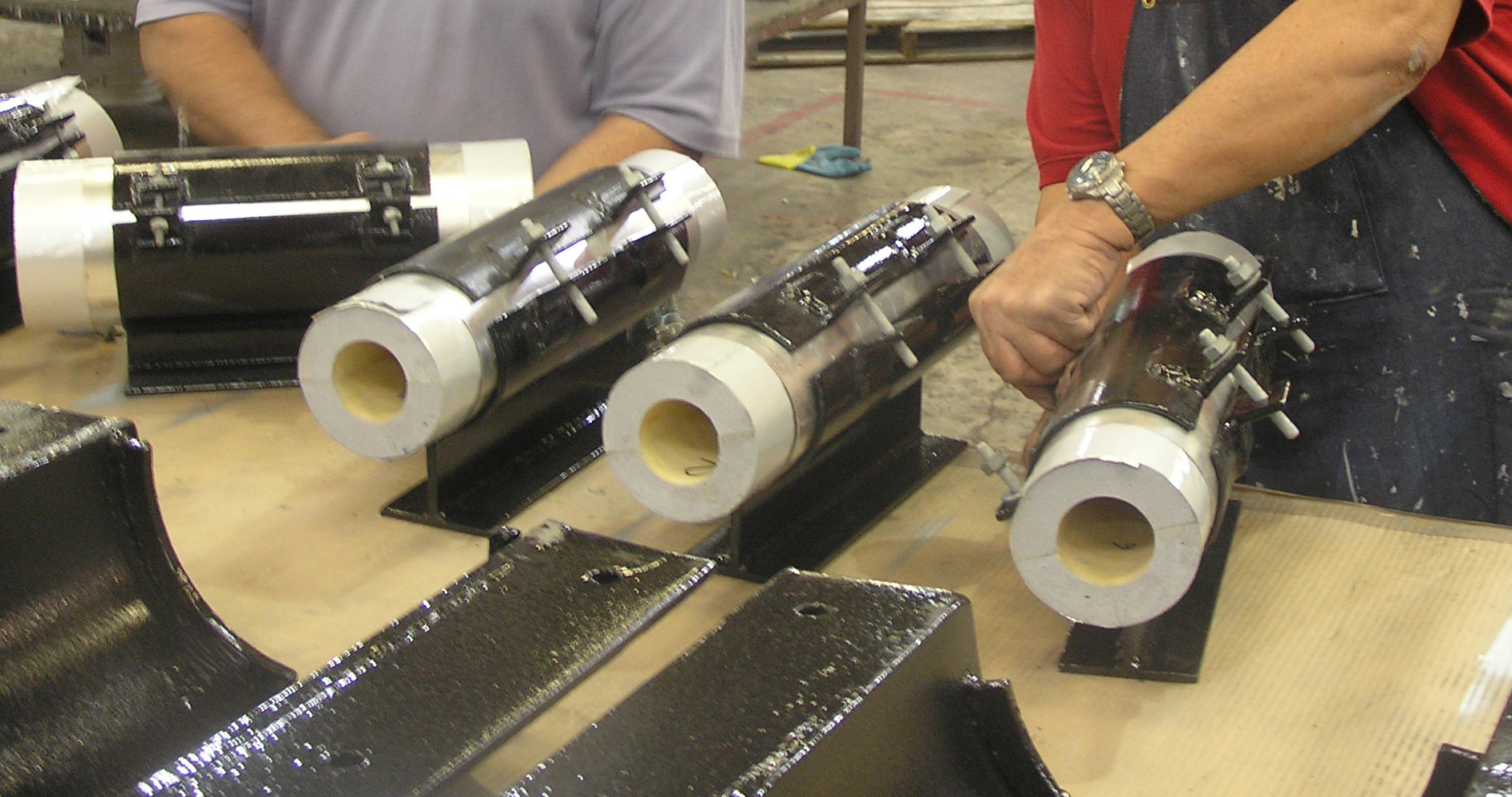

Insulated Supports (Figures 4500 – 4800)

Insulated pipe supports are designed to prevent direct heat transfer between pipes and their supports. Thus, they reduce heat loss due to conduction at each support. They serve the following purposes: Carry the load and allow necessary movement at each suppose point, provide insulation in the support area where the regular pipe insulation cannot be installed and minimize the cost of field installation by reducing installation time. The supports are not welded to the pipe and each unit is shipped completely assembled (except for the riser supports and anchor supports, both of which require some welding).

Acid Plants

Ammonia Plant

Chemical Plant

Clean Fuels

Cogeneration Plant

Cold / Cryogenc Service

Commercial

Electric Plant

Energy Facility

Ethylene Plant

Heat Recovery Steam Generation Plant

Hospital

LLDPE Chemical Plant

LNG Plant

MTBE Plant

See All

General Dimensions & Specifications

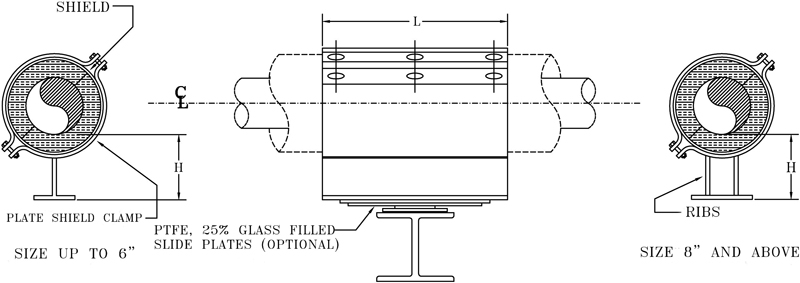

Fig. 4500: Insulated Shoe Support for Hot Pipe (Hot Shoe)

MATERIAL: Shield and jacket – Galvanized carbon steel.

INSULATION: Asbestos free calcium silicate and/or high-density calcium silicate.

BONDING: Insulation, galvanized jacket and shield can be bonded per customer specifications.

OPTIONS: Support design can be modified for length, insulation thickness, higher load and axial movement. Slide plates are available upon request. Please specify by “-SL” after figure number.

HOW TO ORDER: Specify figure number, pipe size, description, insulation, thickness, and slide plate material, if desired.

| PIPE SIZE | H (in.) | L (in.) | AXIAL MVMT. (in.) | LOAD CAPACITY (lb.) | APPROX. WEIGHT (lb.) |

| 3 | 4 | 12 | 4 | 350 | 39 |

| 4 | 4 | 12 | 4 | 375 | 50 |

| 6 | 4 | 12 | 4 | 675 | 77 |

| 8 | 4 | 12 | 4 | 900 | 99 |

| 10 | 4 | 12 | 4 | 1100 | 108 |

| 12 | 4 | 12 | 4 | 1325 | 122 |

| 14 | 4 | 12 | 4 | 1500 | 127 |

| 16 | 4 | 12 | 4 | 1700 | 137 |

| 18 | 4 | 12 | 4 | 1875 | 191 |

| 20 | 4 | 12 | 4 | 2075 | 205 |

| 24 | 4 | 12 | 4 | 2500 | 232 |

“H” dimension given above is based on 2″ insulation thickness. Please mention in your inquiry if it is different than listed above. Contact us for your requirements other than those listed above.

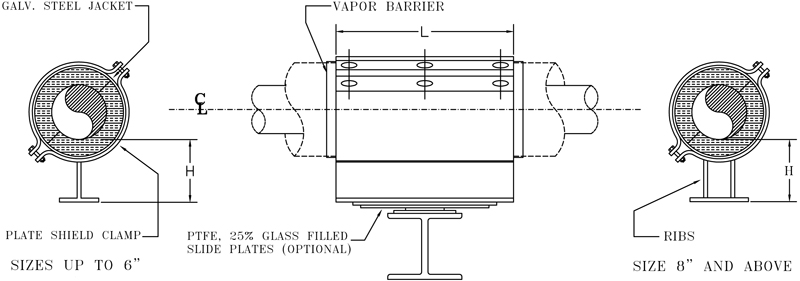

Fig. 4600: Insulated Shoe Support for Cold Pipe (Cold Shoes)

MATERIAL: Shield and jacket – Galvanized carbon steel.

INSULATION: High density Polyurethane (PUF)

BONDING: Galvanized jacket, vapor barrier and polyurethane insulation can be bonded per customer specifications.

COATING: Inside surface of polyurethane insulation is covered with pressure sensitive tape and exposed surfaces are coated with monolar mastic.

OPTIONS: Support design can be modified for length, insulation thickness, higher load capacity, and axial movement. Slide plates are also available upon request. Please specify by “-SL” after figure number.

HOW TO ORDER: Specify figure number, pipe size, description, insulation, thickness, and slide plate material, if desired.

| PIPE SIZE | H (in.) | L (in.) | AXIAL MVMT. (in.) | LOAD CAPACITY (lb.) | APPROX. WEIGHT (lb.) |

| 3 | 4 | 12 | 4 | 320 | 38 |

| 4 | 4 | 12 | 4 | 610 | 44 |

| 6 | 4 | 12 | 4 | 900 | 75 |

| 8 | 4 | 12 | 4 | 1490 | 100 |

| 10 | 4 | 12 | 4 | 1850 | 108 |

| 12 | 4 | 12 | 4 | 2200 | 123 |

| 14 | 4 | 12 | 4 | 5900 | 132 |

| 16 | 4 | 12 | 4 | 6700 | 143 |

| 18 | 4 | 12 | 4 | 7500 | 197 |

| 20 | 4 | 12 | 4 | 8400 | 212 |

| 24 | 4 | 12 | 4 | 10100 | 240 |

“H” dimension given above is based on 2″ insulation thickness. Please mention in your inquiry if it is different than listed above. Contact us for your requirements other than those listed above.

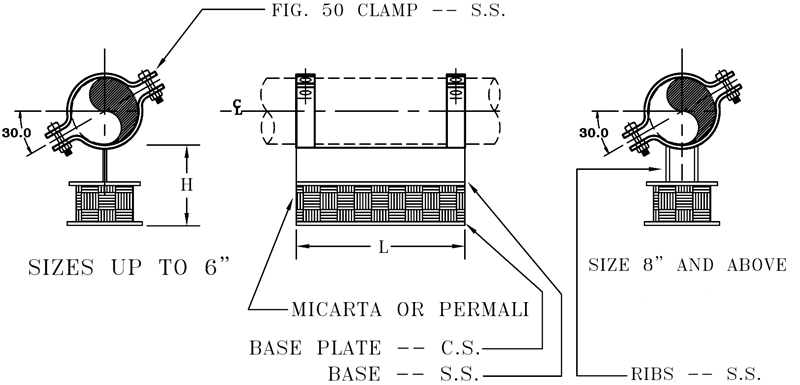

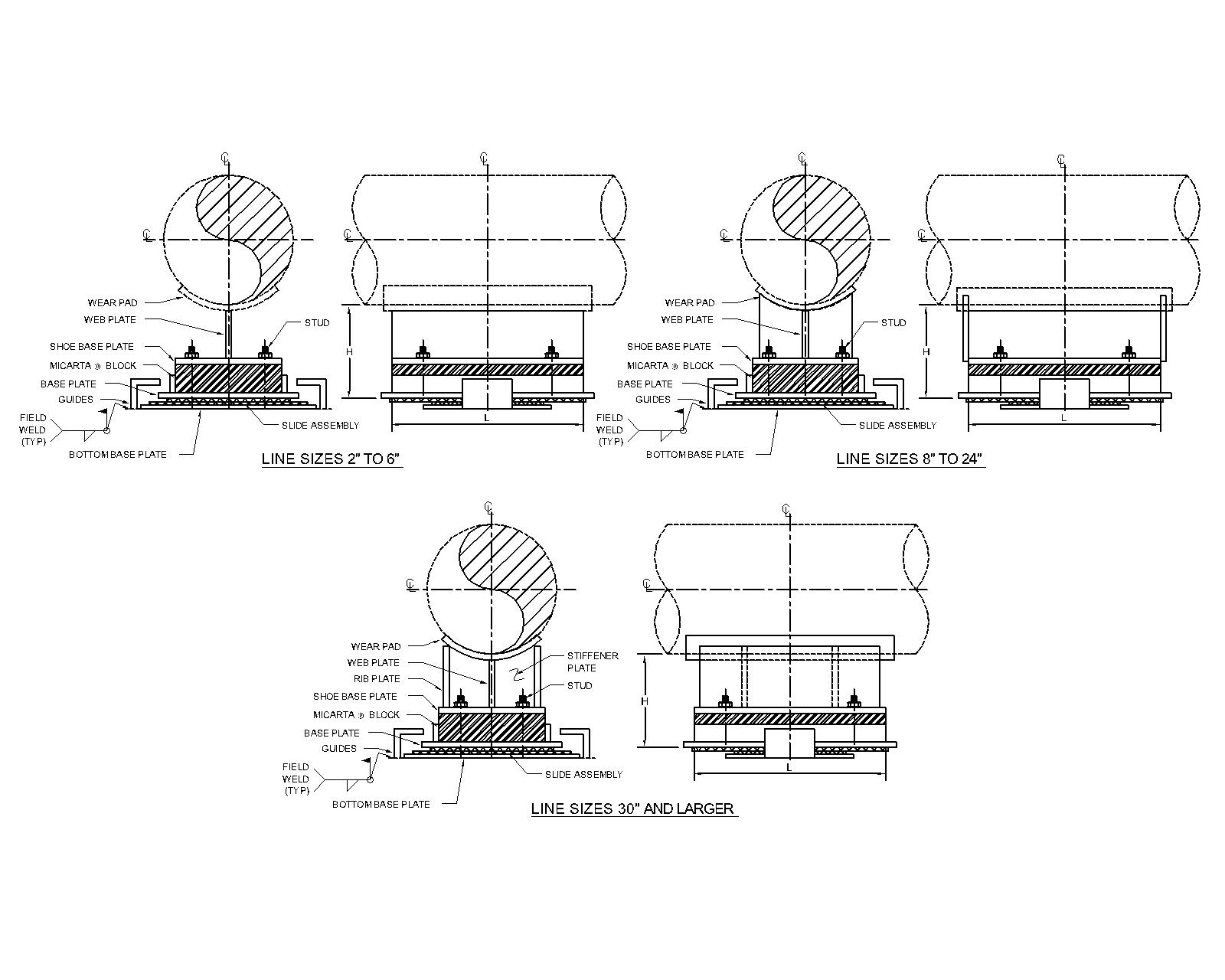

Fig. 4700: Clamped Shoe for Insulated Cold Lines

MATERIAL: Clamps and base – stainless steel. Base plate – carbon steel.

INSULATION: Micarta® or Permali®

OPTIONS: Support design can be modified for length, insulation thickness and axial movement. Slide plates and guides are also available upon request.

HOW TO ORDER: Specify figure number, pipe size and insulation thickness. Also specify any special dimensions.

| PIPE SIZE | H (in.) | L (in.) | Axial Movement (in.) | Vertical Load (lb.) | APPROX. WEIGHT (lb.) |

| 3 | 6 | 12 | 4 | 4000 | 34 |

| 4 | 6 | 12 | 4 | 5000 | 35 |

| 6 | 6 | 12 | 4 | 6000 | 52 |

| 8 | 6 | 12 | 4 | 6000 | 60 |

| 10 | 6 | 12 | 4 | 8000 | 93 |

| 12 | 6 | 12 | 4 | 8000 | 136 |

| 14 | 6 | 12 | 4 | 8000 | 164 |

| 16 | 6 | 12 | 4 | 12000 | 183 |

| 18 | 8 | 12 | 4 | 12000 | 352 |

| 20 | 8 | 12 | 4 | 15000 | 415 |

| 24 | 8 | 12 | 4 | 15000 | 538 |

Contact us for your requirements other than those listed above.

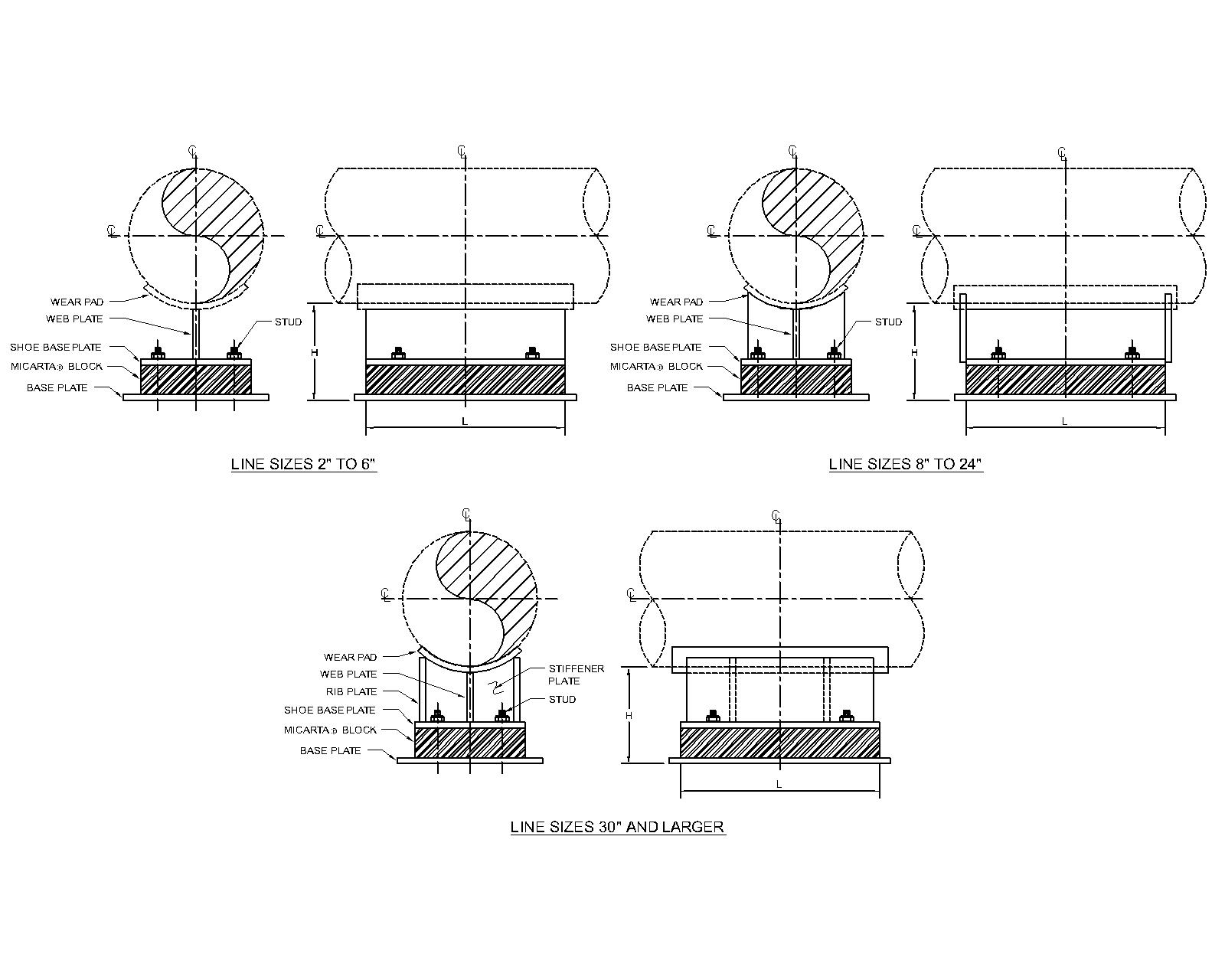

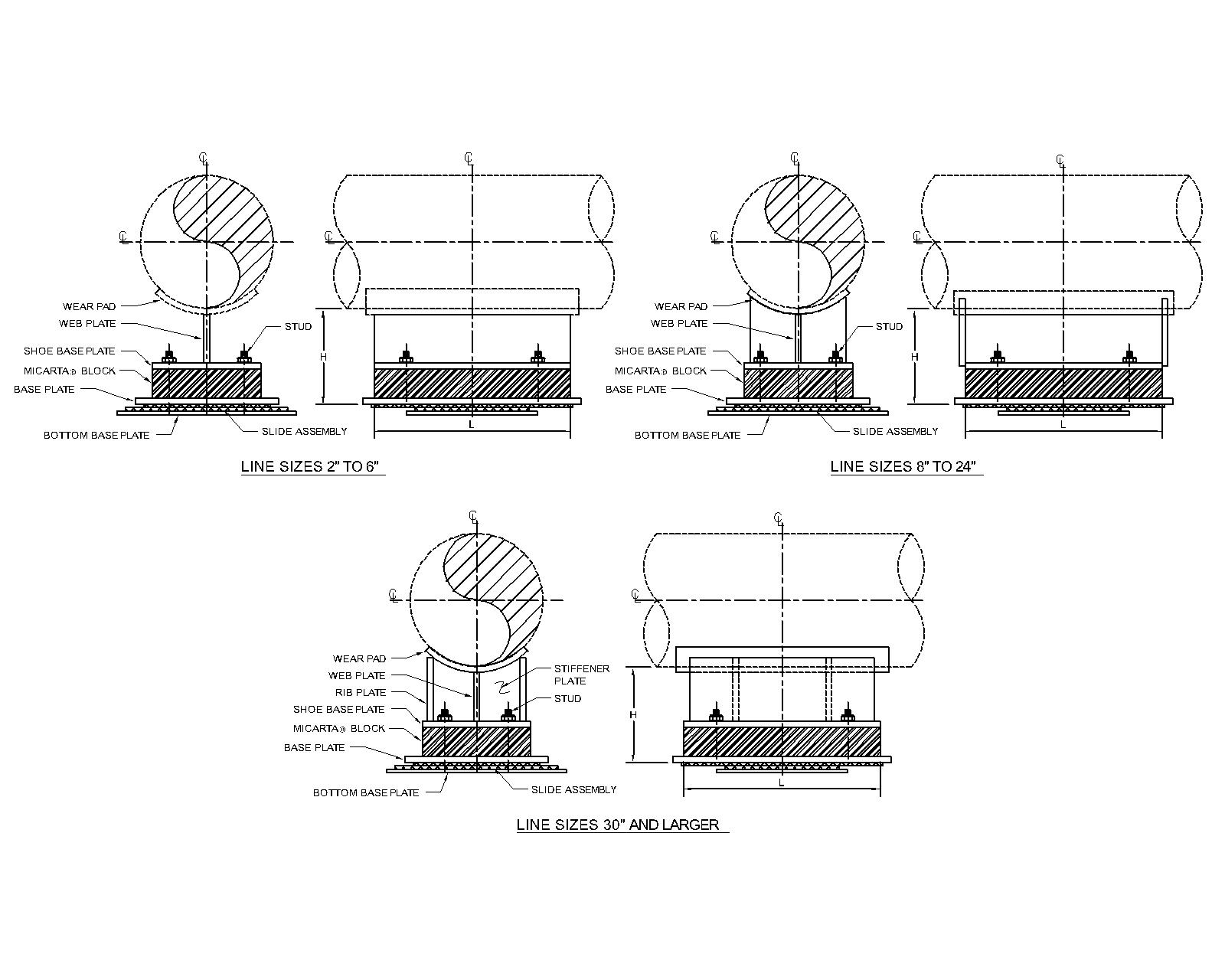

Fig. 4800-A: Insulated Cold Shoe with G10 (Anchor)

SIZE RANGE: 2″ thru 54″

MATERIAL: Shoe: Same as pipe material / Bottom plate: carbon steel

INSULATION: G10

OPTIONS: Support design can be modified for length, insulation thickness and axial movement. Slide plates are provided depending on pipe movement

HOW TO ORDER: Specify figure number, pipe size, description.

| PIPE SIZE | SHOE LENGTH (L) | SHOE HEIGHT (H) | AXIAL LOAD (Lbs) | LATERAL LOAD (Lbs) | COMPRESSION LOAD (Lbs) | AXIAL MOVEMENT (In) |

| 2 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 3 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 4 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 6 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 8 | 12 | 6 | 11,000 | 10,000 | 21,330 | 4 |

| 10 | 12 | 6 | 11,000 | 10,000 | 21,330 | 4 |

| 12 | 12 | 6 | 11,000 | 11,000 | 50,516 | 4 |

| 14 | 12 | 6 | 11,000 | 11,000 | 50,516 | 4 |

| 16 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 18 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 20 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 24 | 18 | 6 | 11,000 | 11,000 | 60,624 | 4 |

| 30 | 18 | 6 | 44,000 | 44,000 | 132,602 | 4 |

| 36 | 24 | 6 | 45,000 | 45,000 | 176,390 | 4 |

| 40 | 24 | 6 | 45,000 | 46,000 | 251,464 | 4 |

| 42 | 24 | 6 | 45,000 | 46,000 | 251,464 | 4 |

| 48 | 24 | 6 | 45,000 | 46,000 | 269,426 | 4 |

| 54 | 24 | 6 | 45,500 | 46,000 | 287,387 | 4 |

Fig. 4800-G: Insulated Cold Shoe with G10 (Guides)

SIZE RANGE: 2″ thru 54″

MATERIAL: Shoe: Same as pipe material / Bottom plate: carbon steel

INSULATION: G10

OPTIONS: Support design can be modified for length, insulation thickness and axial movement. Slide plates are provided depending on pipe movement

HOW TO ORDER: Specify figure number, pipe size, description.

| PIPE SIZE | SHOE LENGTH (L) | SHOE HEIGHT (H) | AXIAL LOAD (Lbs) | LATERAL LOAD (Lbs) | COMPRESSION LOAD (Lbs) | AXIAL MOVEMENT (In) |

| 2 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 3 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 4 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 6 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 8 | 12 | 6 | 11,000 | 10,000 | 21,330 | 4 |

| 10 | 12 | 6 | 11,000 | 10,000 | 21,330 | 4 |

| 12 | 12 | 6 | 11,000 | 11,000 | 50,516 | 4 |

| 14 | 12 | 6 | 11,000 | 11,000 | 50,516 | 4 |

| 16 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 18 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 20 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 24 | 18 | 6 | 11,000 | 11,000 | 60,624 | 4 |

| 30 | 18 | 6 | 44,000 | 44,000 | 132,602 | 4 |

| 36 | 24 | 6 | 45,000 | 45,000 | 176,390 | 4 |

| 40 | 24 | 6 | 45,000 | 46,000 | 251,464 | 4 |

| 42 | 24 | 6 | 45,000 | 46,000 | 251,464 | 4 |

| 48 | 24 | 6 | 45,000 | 46,000 | 269,426 | 4 |

| 54 | 24 | 6 | 45,500 | 46,000 | 287,387 | 4 |

Fig. 4800-S: Insulated Cold Shoe with G10 (Slides)

SIZE RANGE: 2″ thru 54″

MATERIAL: Shoe: Same as pipe material / Bottom plate: carbon steel

INSULATION: G10

OPTIONS: Support design can be modified for length, insulation thickness and axial movement. Slide plates are provided depending on pipe movement

HOW TO ORDER: Specify figure number, pipe size, description.

| PIPE SIZE | SHOE LENGTH (L) | SHOE HEIGHT (H) | AXIAL LOAD (Lbs) | LATERAL LOAD (Lbs) | COMPRESSION LOAD (Lbs) | AXIAL MOVEMENT (In) |

| 2 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 3 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 4 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 6 | 12 | 6 | 7,000 | 2,371 | 20,207 | 4 |

| 8 | 12 | 6 | 11,000 | 10,000 | 21,330 | 4 |

| 10 | 12 | 6 | 11,000 | 10,000 | 21,330 | 4 |

| 12 | 12 | 6 | 11,000 | 11,000 | 50,516 | 4 |

| 14 | 12 | 6 | 11,000 | 11,000 | 50,516 | 4 |

| 16 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 18 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 20 | 12 | 6 | 11,000 | 11,000 | 50,517 | 4 |

| 24 | 18 | 6 | 11,000 | 11,000 | 60,624 | 4 |

| 30 | 18 | 6 | 44,000 | 44,000 | 132,602 | 4 |

| 36 | 24 | 6 | 45,000 | 45,000 | 176,390 | 4 |

| 40 | 24 | 6 | 45,000 | 46,000 | 251,464 | 4 |

| 42 | 24 | 6 | 45,000 | 46,000 | 251,464 | 4 |

| 48 | 24 | 6 | 45,000 | 46,000 | 269,426 | 4 |

| 54 | 24 | 6 | 45,500 | 46,000 | 287,387 | 4 |

Size Range: For use with 1/2″ through 72″, most designs. insulation thickness of 1″. 1-1/2″, 2″, 2-1/2″, 3″, 3-1/2″, 4″ and larger sizes where specified.

How to Size: Refer to “Insulation Chart” below for Sizing the Insulation Material.

Ordering: Specify figure number, pipe size, insulation thickness, and insulating material

Example:

Fig. 4700-4-3-B

• 4700 = Type of Insulated Shoe (cold)

• 4 = Nominal Pipe Size

• 3= Insulation Thickness

• B = Insulation Material (Micarta)

| NOMINAL INSULATION THICKNESS (in.) | INSULATION O.D. (in.) | APPROX. INSULATION THICKNESS (in.) |

Pipe size: 1/2" (O.840 O.D.) |

||

| 1 | 2 7/8 | 1 |

| 1 1/2 | 4 | 1 9/16 |

| 2 | 5 | 2 1/16 |

| 2 1/2 | 6 5/8 | 2 7/8 |

| 3 | 7 5/8 | 3 3/8 |

| 3 1/2 | 8 5/8 | 3 7/8 |

| 4 | 9 5/8 | 4 3/8 |

Pipe size: 3/4" (1.050 O.D.) |

||

| 1 | 2 7/8 | 7/8 |

| 1 1/2 | 4 | 1 7/16 |

| 2 | 5 | 1 15/16 |

| 2 1/2 | 6 5/8 | 2 3/4 |

| 3 | 7 5/8 | 3 1/4 |

| 3 1/2 | 8 5/8 | 3 3/4 |

| 4 | 9 5/8 | 4 1/4 |

Pipe size: 1" (1.315 O.D.) |

||

| 1 | 3 1/2 | 1 1/16 |

| 1 1/2 | 4 1/2 | 1 9/16 |

| 2 | 5 9/16 | 2 1/8 |

| 2 1/2 | 6 5/8 | 2 5/8 |

| 3 | 7 5/8 | 3 1/8 |

| 3 1/2 | 8 5/8 | 3 5/8 |

| 4 | 9 5/8 | 4 1/8 |

Pipe size: 1 1/4" (1.66 O.D.) |

||

| 1 | 3 1/2 | 15/16 |

| 1 1/2 | 5 | 1 11/16 |

| 2 | 5 9/16 | 1 15/16 |

| 2 1/2 | 6 5/8 | 2 1/2 |

| 3 | 7 5/8 | 3 |

| 3 1/2 | 8 5/8 | 3 1/2 |

| 4 | 9 5/8 | 4 |

Pipe size: 1 1/2" (1.90 O.D.) |

||

| 1 | 4 | 1 1/16 |

| 1 1/2 | 5 | 1 9/16 |

| 2 | 6 5/8 | 2 3/8 |

| 2 1/2 | 7 5/8 | 2 7/8 |

| 3 | 8 5/8 | 3 3/8 |

| 3 1/2 | 9 5/8 | 3 7/8 |

| 4 | 10 3/4 | 4 7/16 |

Pipe size: 2" (2 3/8" O.D.) |

||

| 1 | 4 1/2 | 1 1/16 |

| 1 1/2 | 5 9/16 | 1 9/16 |

| 2 | 6 5/8 | 2 1/8 |

| 2 1/2 | 7 5/8 | 2 5/8 |

| 3 | 8 5/8 | 3 1/8 |

| 3 1/2 | 9 5/8 | 3 5/8 |

| 4 | 10 3/4 | 4 3/16 |

Pipe size: 2 1/2" (2 7/8" O.D.) |

||

| 1 | 5 | 1 1/16 |

| 1 1/2 | 6 5/8 | 1 7/8 |

| 2 | 7 5/8 | 2 3/8 |

| 2 1/2 | 8 5/8 | 2 7/8 |

| 3 | 9 5/8 | 3 3/8 |

| 3 1/2 | 10 3/4 | 3 15/16 |

| 4 | 11 3/4 | 4 7/16 |

Pipe size: 3" (3 1/2" O.D.) |

||

| 1 | 5 9/16 | 1 |

| 1 1/2 | 6 5/8 | 1 9/16 |

| 2 | 7 5/8 | 2 1/16 |

| 2 1/2 | 8 5/8 | 2 9/16 |

| 3 | 9 5/8 | 3 1/16 |

| 3 1/2 | 10 3/4 | 3 5/8 |

| 4 | 11 3/4 | 4 1/8 |

Pipe size: 3 1/2" (4" O.D.) |

||

| 1 | 6 5/8 | 1 5/16 |

| 1 1/2 | 7 5/8 | 1 13/16 |

| 2 | 8 5/8 | 2 5/16 |

| 2 1/2 | 9 5/8 | 2 13/16 |

| 3 | 10 3/4 | 3 3/8 |

| 3 1/2 | 11 3/4 | 3 7/8 |

| 4 | 12 3/4 | 4 3/8 |

Pipe size: 4" (4 1/2" O.D.) |

||

| 1 | 6 5/8 | 1 1/16 |

| 1 1/2 | 7 5/8 | 1 9/16 |

| 2 | 8 5/8 | 2 1/16 |

| 2 1/2 | 9 5/8 | 2 9/16 |

| 3 | 10 3/4 | 3 1/8 |

| 3 1/2 | 11 3/4 | 3 5/8 |

| 4 | 12 3/4 | 4 1/8 |

Pipe size: 4 1/2" (5" O.D.) |

||

| 1 | 7 5/8 | 1 5/16 |

| 1 1/2 | 8 5/8 | 1 13/16 |

| 2 | 9 5/8 | 2 5/16 |

| 2 1/2 | 10 3/4 | 2 7/8 |

| 3 | 11 3/4 | 3 3/8 |

| 3 1/2 | 12 3/4 | 3 7/8 |

| 4 | 14 | 4 1/2 |

Pipe size: 5" (5 9/16" O.D.) |

||

| 1 | 7 5/8 | 1 |

| 1 1/2 | 8 5/8 | 1 1/2 |

| 2 | 9 5/8 | 2 |

| 2 1/2 | 10 3/4 | 2 9/16 |

| 3 | 11 3/4 | 3 1/16 |

| 3 1/2 | 12 3/4 | 3 9/16 |

| 4 | 14 | 4 3/16 |

Pipe size: 6" (6 5/8" O.D.) |

||

| 1 | 8 5/8 | 15/16 |

| 1 1/2 | 9 5/8 | 1 7/16 |

| 2 | 10 3/4 | 2 |

| 2 1/2 | 11 3/4 | 2 1/2 |

| 3 | 12 3/4 | 3 |

| 3 1/2 | 14 | 3 5/8 |

| 4 | 15 | 4 1/8 |

Pipe size: 7" (7 5/8" O.D.) |

||

| 1 | 9 5/8 | 1 |

| 1 1/2 | 10 3/4 | 1 1/2 |

| 2 | 11 3/4 | 2 |

| 2 1/2 | 12 3/4 | 2 1/2 |

| 3 | 14 | 3 1/8 |

| 3 1/2 | 15 | 3 5/8 |

| 4 | 16 | 4 1/8 |

Pipe size: 8" (8 5/8" O.D.) |

||

| 1 | 10 3/4 | 1 1/16 |

| 1 1/2 | 11 3/4 | 1 1/2 |

| 2 | 12 3/4 | 2 |

| 2 1/2 | 14 | 2 5/8 |

| 3 | 15 | 3 1/8 |

| 3 1/2 | 16 | 3 5/8 |

| 4 | 17 | 4 1/8 |

Pipe size: 9" (9 5/8" O.D.) |

||

| 1 | 11 3/4 | 1 1/16 |

| 1 1/2 | 12 3/4 | 1 1/2 |

| 2 | 14 | 2 |

| 2 1/2 | 15 | 2 5/8 |

| 3 | 16 | 3 1/8 |

| 3 1/2 | 17 | 3 5/8 |

| 4 | 18 | 4 1/8 |

Pipe size: 10" (10 3/4" O.D.) |

||

| 1 | 12 3/4 | 1 |

| 1 1/2 | 14 | 1 9/16 |

| 2 | 15 | 2 1/16 |

| 2 1/2 | 16 | 2 9/16 |

| 3 | 17 | 3 1/16 |

| 3 1/2 | 18 | 3 9/16 |

| 4 | 19 | 4 1/16 |

Pipe size: 11" (11 3/4" O.D.) |

||

| 1 | 14 | 1 1/8 |

| 1 1/2 | 15 | 1 9/16 |

| 2 | 16 | 2 1/16 |

| 2 1/2 | 17 | 2 9/16 |

| 3 | 18 | 3 1/16 |

| 3 1/2 | 19 | 3 9/16 |

| 4 | 20 | 4 1/16 |

Pipe size: 12" (12 3/4" O.D.) |

||

| 1 | 15 | 1 1/8 |

| 1 1/2 | 16 | 1 9/16 |

| 2 | 17 | 2 1/16 |

| 2 1/2 | 18 | 2 9/16 |

| 3 | 19 | 3 1/16 |

| 3 1/2 | 20 | 3 9/16 |

| 4 | 21 | 4 1/16 |

Pipe size: 14" (14" O.D.) |

||

| 1 | 16 | 2 |

| 1 1/2 | 17 | 1 7/16 |

| 2 | 18 | 1 15/16 |

| 2 1/2 | 19 | 2 7/16 |

| 3 | 20 | 2 15/16 |

| 3 1/2 | 21 | 3 7/16 |

| 4 | 22 | 3 15/16 |

| Large sizes, insulation O.D. are in 1" increments. Insulation thicknesses through 36" same as nominal. All dimensions rounded to the nearest 1/16". |

||

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});