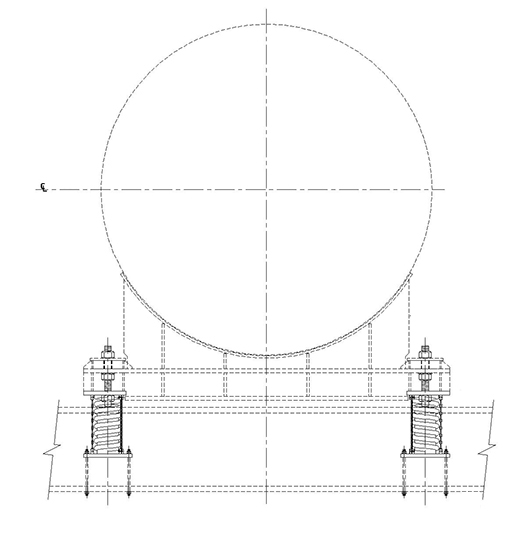

| Type: | Variable Spring Supports with Graphite Slide Plates |

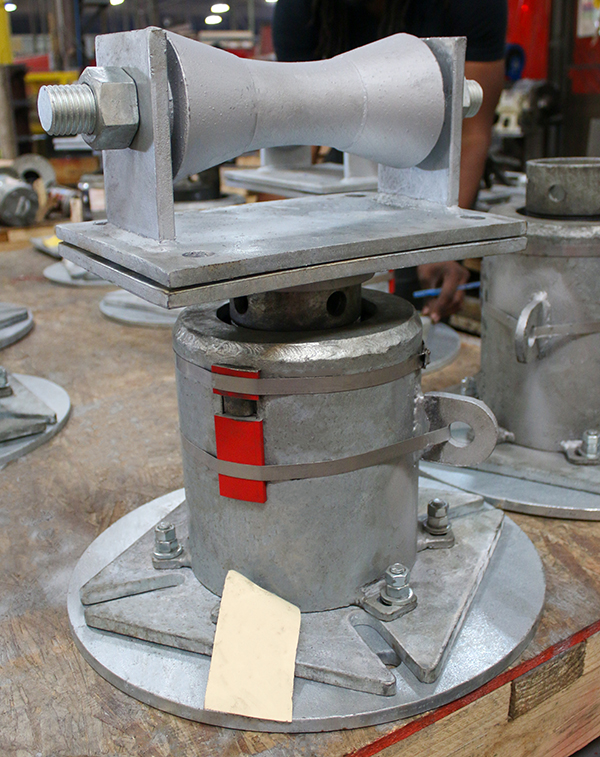

| Materials: | CS | HDG | High Heat Aluminum Finish | Graphite |

| Load Range: | 420 lb. to 7650 lb. | 0.65″ Upward Movement |

| Design: | 700°F Temperature | Q.C. & Load Tests |

PT&P custom designed an F-type variable spring supports with graphite slide plates for an oil refinery in California. Client inspection O.C. inspections and load tests were conducted prior to shipment.

The graphite slide plates are used to accommodate the axial and lateral movement of the pipeline. Each assembly is equipped with specially designed “round” base plates (instead of the standard square plates) and is designed for temperatures up to 700°F. The spring cans are designed for a load range from 420 lb. to 7,650 lb. and movements up to 0.65″. In this case, they are finished with high-heat aluminum instead of our standard hot-dipped galvanized finish due to the high-temperature requirements in which these units will be operating. We have the unique capability to work with different materials based on the design needs. Variable spring supports, along with our array of engineered support solutions, stand as a fundamental pillar of our business. They enable us to actively collaborate with our clients, whether it involves the products we’ve manufactured, systems subjected to pipe stress and Finite Element Analysis (FEA), or items serviced through the expertise of our field service team.

For many of our products, we have the ability to build and deliver support in less than 24 hours should an emergency arise. It is useful to keep our emergency information handy on your phone and computers should an unforeseen moment arise. Please share this with your maintenance, fixed equipment, and reliability teams. To bookmark or for more information about our emergency assistance, please click here.

PT&P REF. ORIGINAL POST 09242018

Read More